Anti-blocking type slag discharging system for slag scraper

A slag scraper and anti-blocking technology, applied in water/sewage multi-stage treatment, flotation water/sewage treatment, centrifugal separation water/sewage treatment, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

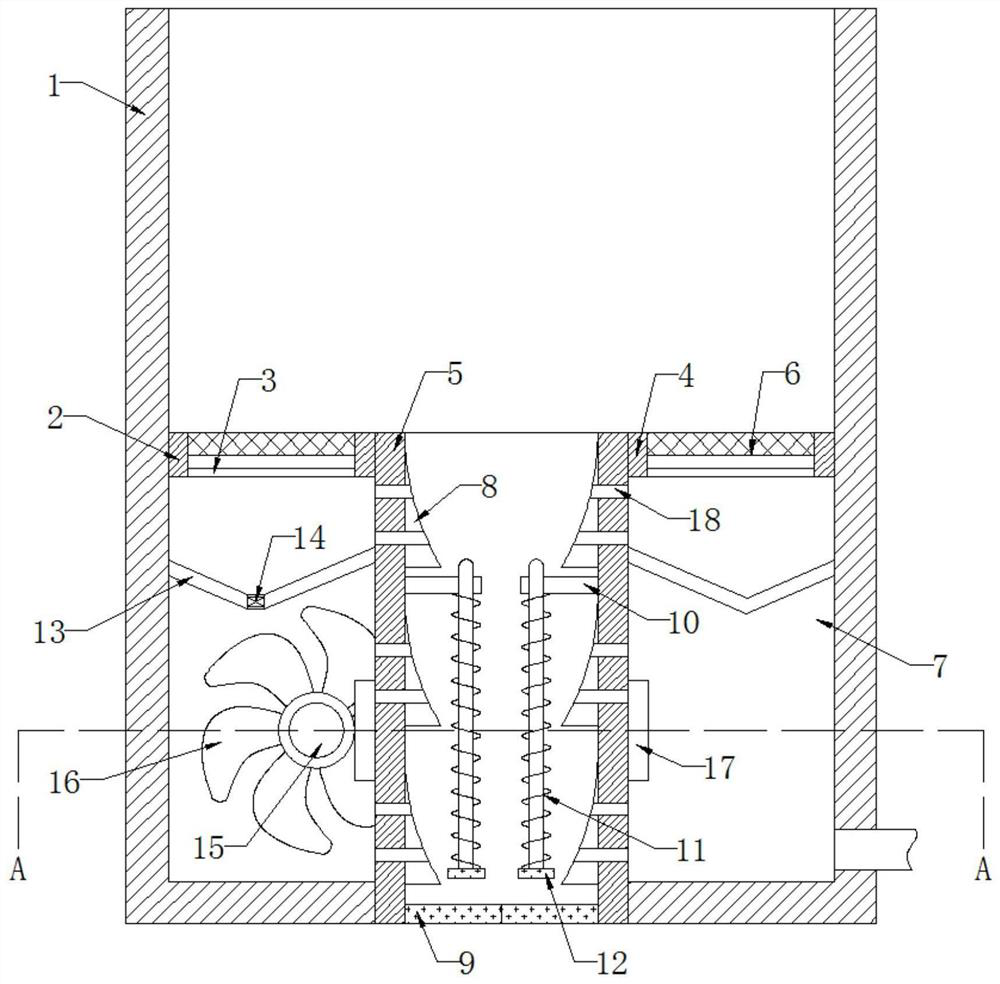

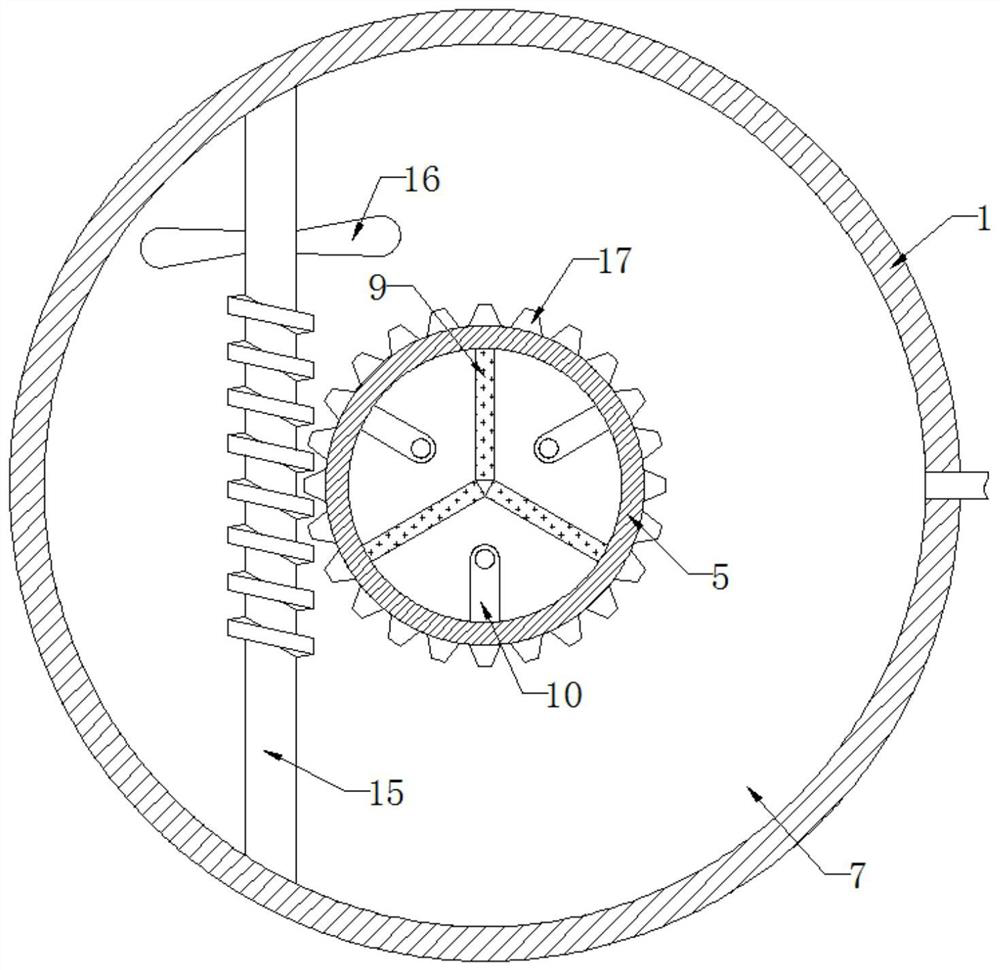

[0021] refer to Figure 1-2 , an anti-blocking slag discharge system for a slag scraper, comprising a slag collection box 1, a first circular ring 2 fixedly connected to the inner wall of the slag collection box 1, and a second circular ring 2 fixedly connected to the inner wall of the first circular ring 2 through a fixed rod 3 Ring 4, a filter screen 6 is fixedly connected between the first ring 2 and the second ring 4. Further, the filter screen 6 can filter, discharge and collect the sewage in the waste residue to avoid waste of water resources. The second ring 4 The inner wall is slidably connected with a slag discharge tube 5, the lower end of the slag discharge tube 5 runs through the lower end of the slag collection box 1 and is slidably connected with its side wall. pipe, which is convenient for the discharge and collection of sewage. The inner wall of the slag discharge cylinder 5 is fixedly connected with a plurality of arc-shaped deflectors 8 at equal intervals alo...

Embodiment 2

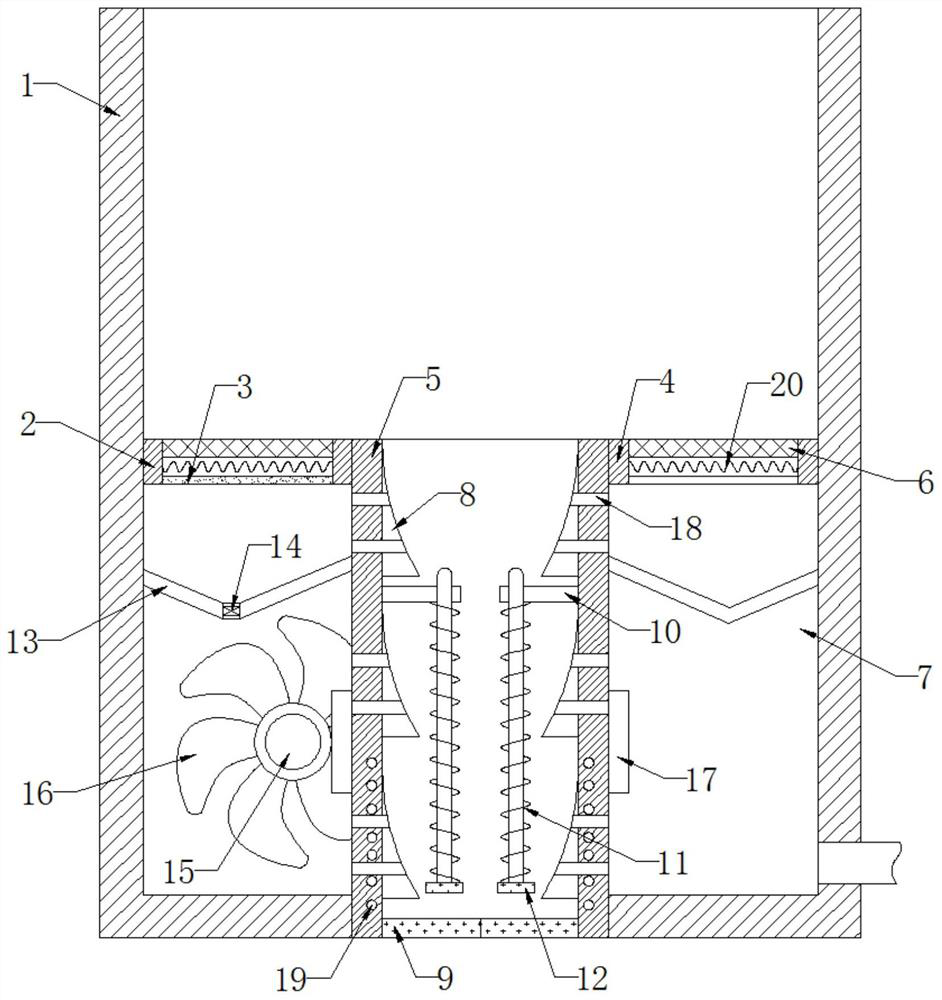

[0025] refer to image 3 , the difference from the first embodiment is that the fixed rod 3 is an electromagnetic fixed rod, and a helical coil 19 is embedded under the inner wall of the slag discharge cylinder 5, and the helical coil 19 is coupled with the fixed rod 3 through a switch module. Further, the helical coil 19 is The irregular setting makes the magnetic flux always change when the helical coil 19 cuts the magnetic induction line. The switch module is a rectangular wave generating module that alternately outputs high voltage and low voltage, so that the helical coil 19 can discontinuously control the fixed rod 3. Power is supplied, and then the fixed rod 3 is continuously magnetized and demagnetized periodically, and a vibrating spring 20 is fixedly connected under the inner walls of the first ring 2 and the second ring 4 .

[0026] In this embodiment, when the thimble 12 continuously moves up and down on the inner wall of the slag discharge cylinder 5 under the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com