Environment-friendly water-based nano color paste and preparation method thereof

A nano-color paste, water-based color paste technology, applied in the direction of pigment paste, ink, household appliances, etc., can solve the problems of low color paste stability and short shelf life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

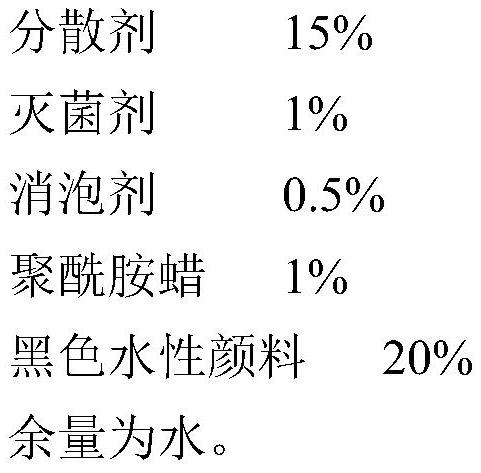

Embodiment 1

[0047] According to a kind of environment-friendly water-based nano color paste proposed by the present invention and preparation method thereof, at first, prepare each component of following weight ratio, altogether 20Kg:

[0048]

[0049] Surplus is water, and in the present embodiment, what dispersant adopts is Germany Digao 740 water-based dispersant, what sterilant adopts is Dow 7287, and the kind of sterilant is a lot, in the product of the present invention, basically as long as can Satisfy the effect of sterilization, and at the same time, non-toxic or low-toxic sterilizers to the human body can be used. The polyamide wax is Changxing Xiehe, and the models that can be used for water-based pigments can be domestic or imported.

[0050] Specifically, the proportion of water-based pigments in the environmentally friendly water-based nano-color paste accounts for 15-30%, which is higher than the traditional 15%, so the color is brighter when printing and saves costs; amo...

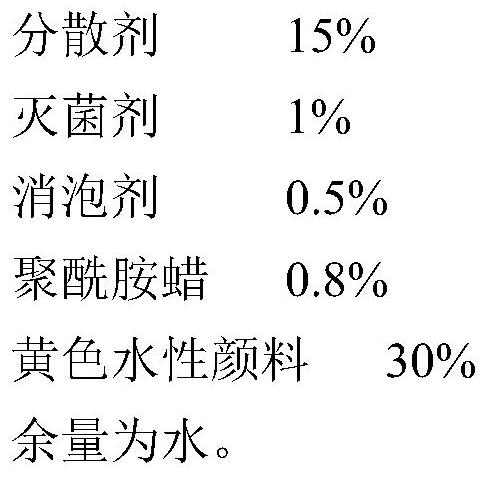

Embodiment 2

[0074] The preparation method of embodiment 2 is identical with embodiment 1, and difference is only in the weight ratio of each component, totally 20Kg, as follows:

[0075]

[0076] The d(0.1) is 0.035um, the d(0.5) is 0.060um, and the d(0.9) is 0.093um as measured by a Malvern particle size analyzer (model: MASTERSIZER 2000).

[0077] Compared with embodiment 1, embodiment 2 increases the proportion of pigment, and the beneficial effects are basically the same.

Embodiment 3

[0079] The preparation method of embodiment 3 is the same as embodiment 1, and the difference is only in the weight ratio of each component, as follows:

[0080]

[0081] The d(0.1) is 0.038um, the d(0.5) is 0.066um, and the d(0.9) is 0.098um as measured by a Malvern particle size analyzer (model: MASTERSIZER 2000).

[0082] Compared with embodiment 1, embodiment 3 further increases the proportion of pigment, and the beneficial effect is basically the same.

[0083] Implementation 1, Example 2, and Example 3 can be seen after being detected by the Malvern particle size analyzer, the product obtained by the method and formula ratio disclosed by the present invention has reached the nanometer level, the performance is more prominent, and the scope of application is wider.

[0084] Further, after verifying the particle size of the product, the stability of the product was also tested, and the obtained product was stored for 12 months before testing. The particle size of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com