Transmission tower foundation treatment method for power plant

A transmission tower and foundation treatment technology, applied to towers, foundation structure engineering, sheet pile walls, etc., can solve problems such as easy collapse of the inner wall of the foundation pit, increased construction costs, and increased concrete spillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

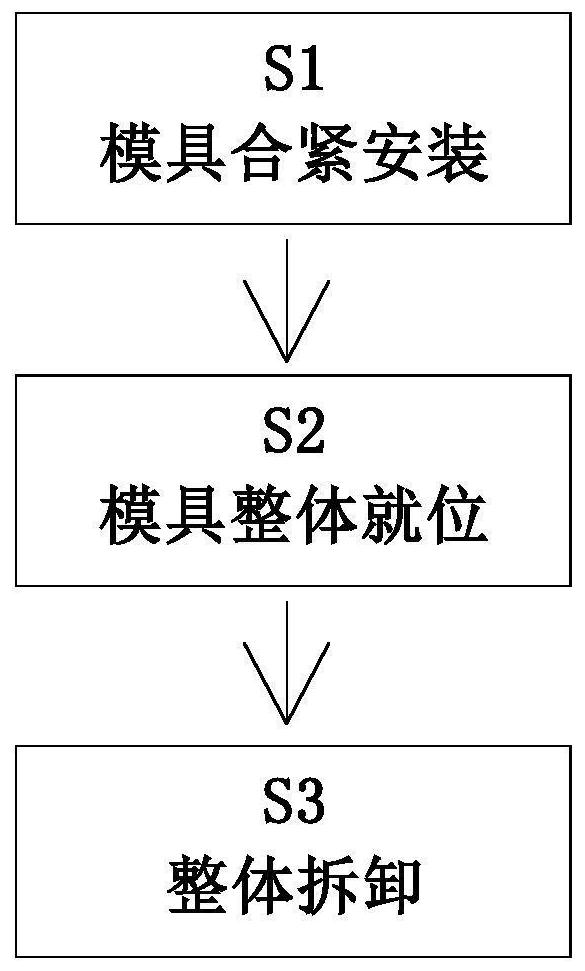

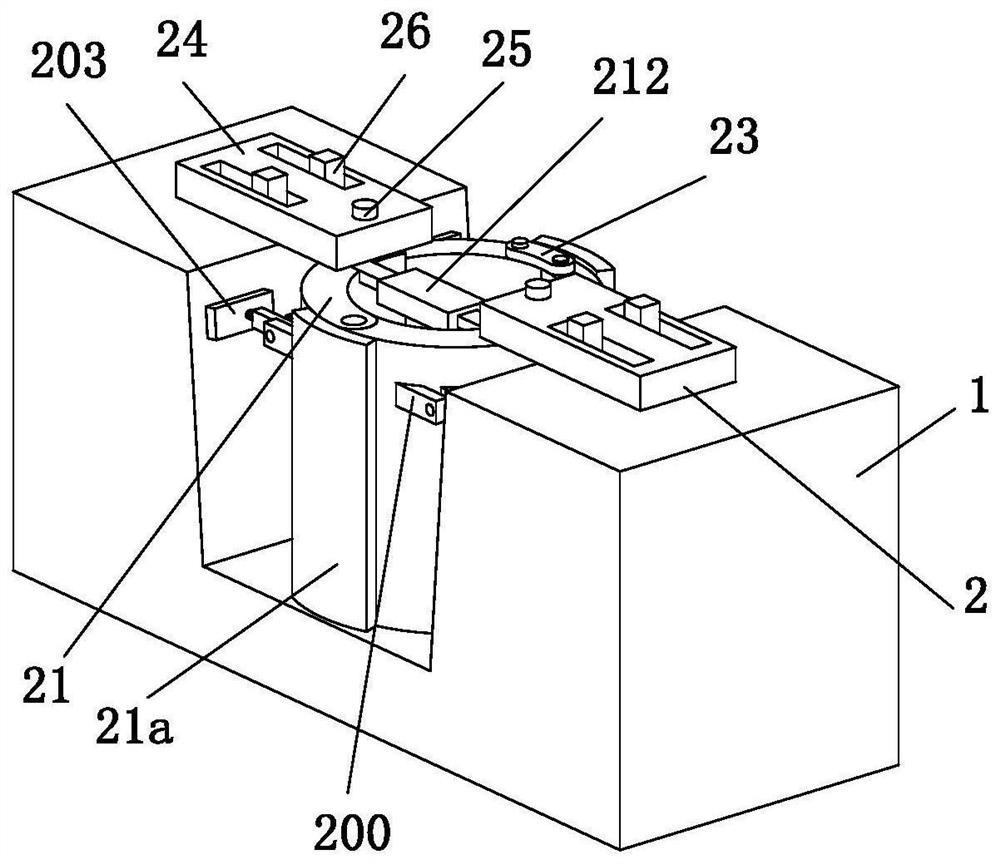

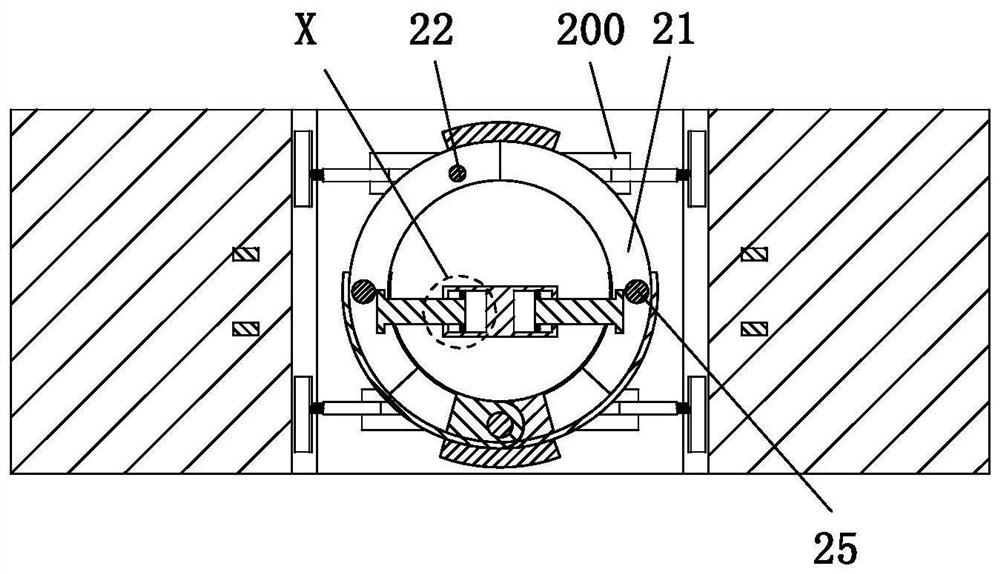

[0034] Such as Figure 1 to Figure 9 As shown, a power plant transmission tower foundation treatment method uses a power plant transmission tower foundation treatment device. The power plant transmission tower foundation treatment device includes a foundation pit 1 and a mold sleeve mechanism 2. The specific treatment methods for the foundation treatment of power plant transmission towers by the ground treatment device are as follows:

[0035] S1. Mold tightening installation: Tighten the bolts 25 manually to fix the fixing plate 24 on the arc formwork 21, and then manually turn the arc formwork 21 inward so that the two arc formworks 21 form a complete hollow column structure, At the same time, the left end of the elastic clip 23 is clamped on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com