Lump coal-pulverized coal integration gasification furnace and lump coal-pulverized coal integration gasification method

A gasifier and lump powder technology, applied in the field of coal chemical industry, can solve the problems of complicated process flow, one-time investment and operation cost, management cost and difficulty increase, etc., to solve the problem of balance and furnace selection, The effect of wide selection of coal types, reducing investment costs and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

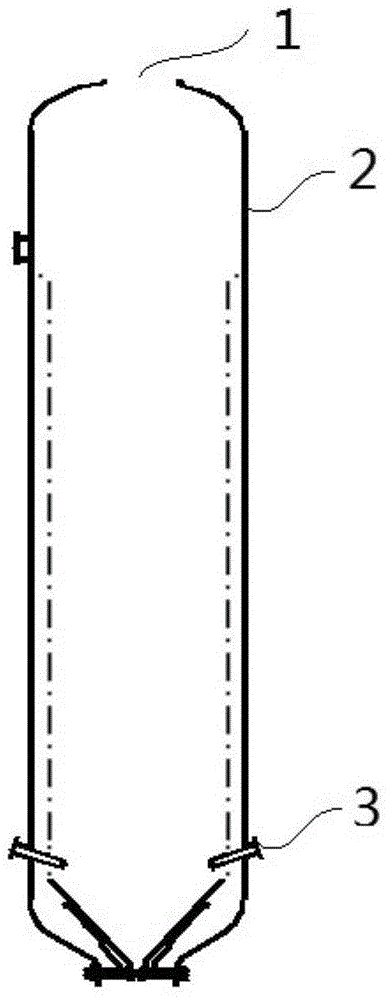

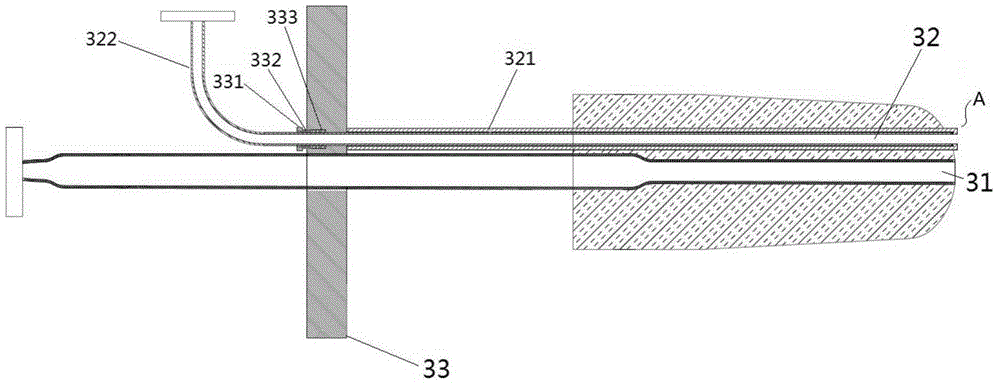

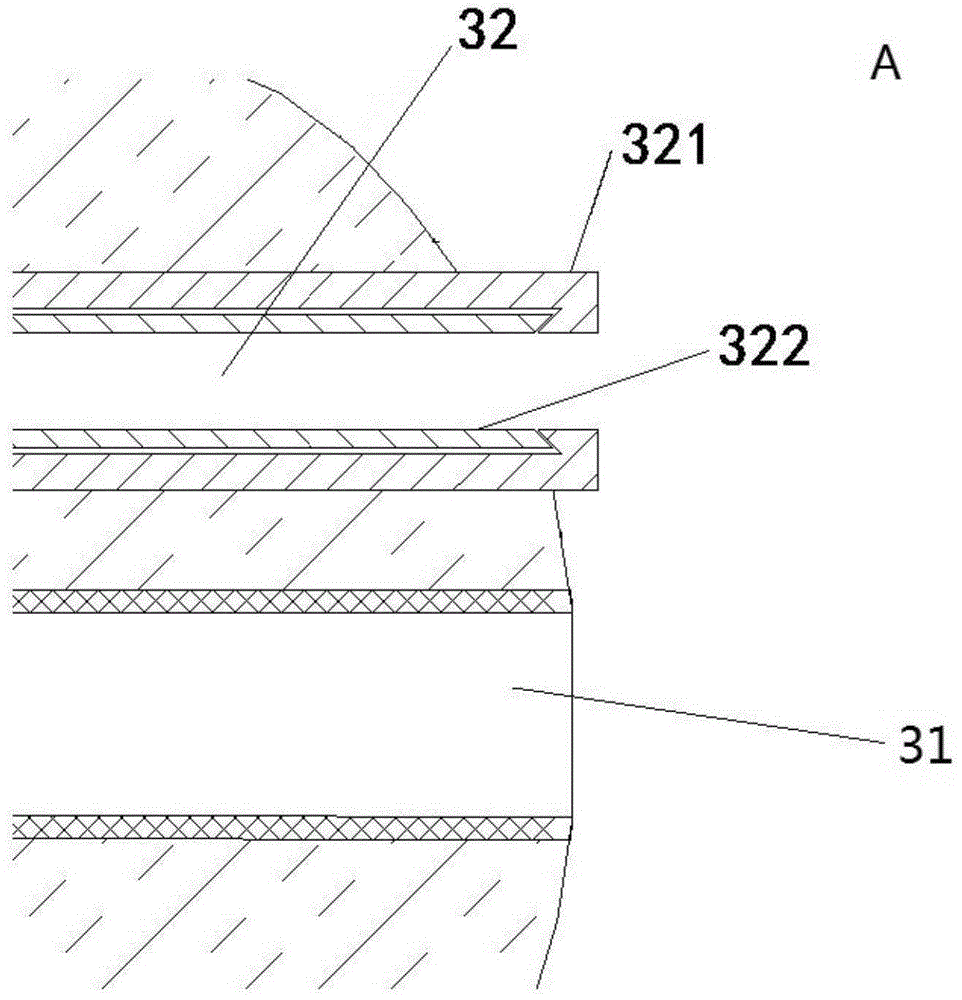

[0044] A plurality of nozzles 3 located at the lower part of the furnace body 2 can be used to respectively introduce gasification agent and pulverized coal into the furnace body 2, wherein some nozzles 3 are used to introduce gasification agent, and the remaining nozzles 3 are used to introduce pulverized coal. The pulverized coal in the raw material is carried by the carrier gas into the furnace body 2 through the pulverized coal channel 32 in the nozzle 3 by way of gas transportation. As an embodiment, the carrier gas is nitrogen.

[0045] As a preferred embodiment of the present application, the furnace body 2 is a pressurized furnace body.

[0046] As a specific embodiment of the present application, the plurality of nozzles 3 are single-channel nozzles with only one channel. Among them, the passages in several nozzles 3 are pulverized coal passages 32 for introducing pulverized coal into the furnace body 2 ; the passages in the remaining nozzles 3 are gasification agent p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com