Open shoulder center positioning device for plate tensile sample

A tensile specimen, center positioning technology, applied in the direction of using optical devices, measuring devices, using stable tension/pressure to test the strength of materials, etc., can solve the problems of different sizes, false detection, and reduced automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further illustrated below in conjunction with the accompanying drawings and specific examples, and these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

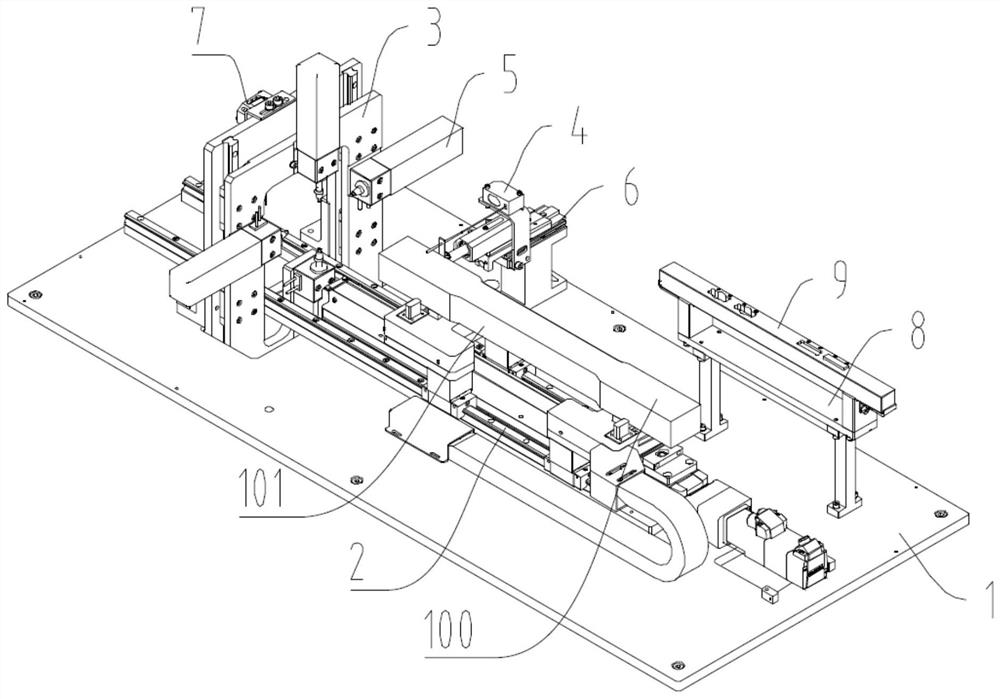

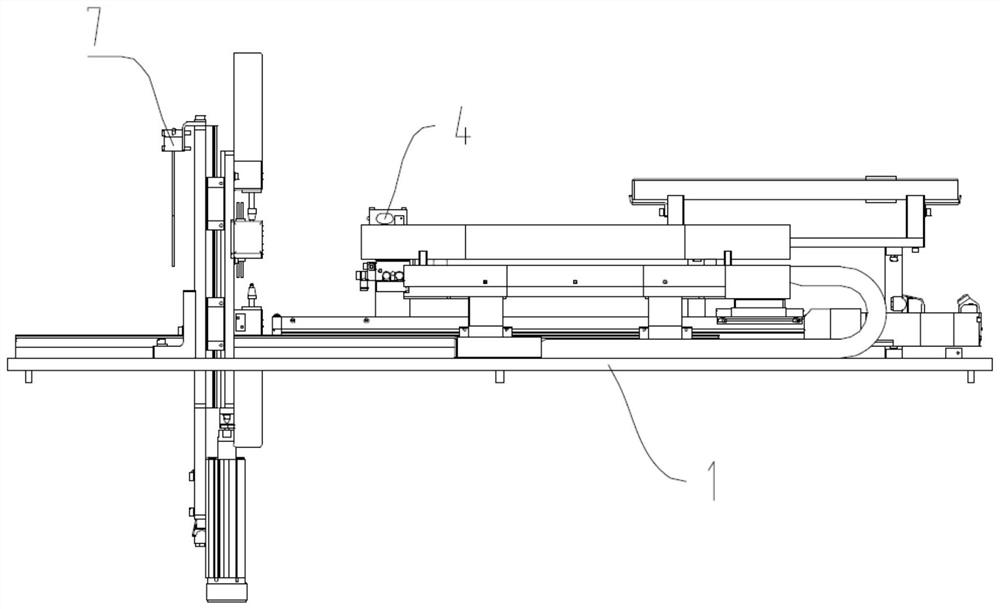

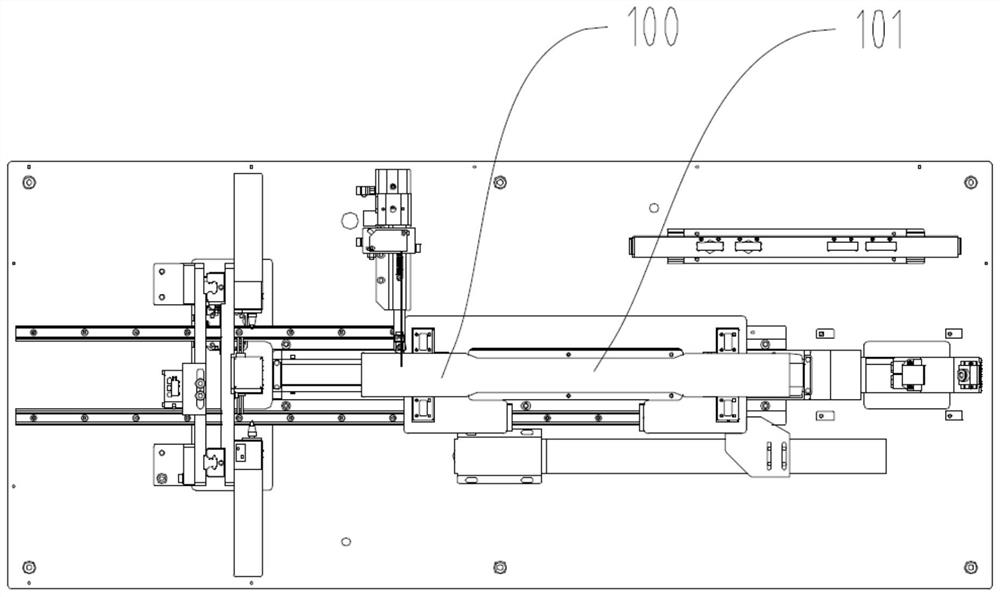

[0032] An open shoulder centering device for sheet tensile specimens, as attached Figure 1~3 As shown, it includes workbench 1, lateral sliding mechanism 2, vertical sliding mechanism 3, first laser distance measuring sensor 4, length meter group 5, auxiliary positioning mechanism 6, second laser distance measuring sensor 7, standard sample storage rack8.

[0033]The lateral sliding mechanism 2, the vertical sliding mechanism 3, and the first laser ranging sensor 4 are fixed on the workbench 1, and the sheet tensile sample 100 is fixed on the lateral sliding mechanism 2, and Driven to move laterally; the first laser ranging sensor 4 is set in alignment with the side wall of the sheet tensile sample 100 to identify t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com