Method for testing wrinkling performance of plate based on uniaxial tension of perforated sample

A technology of unidirectional stretching and testing methods, which is applied in the direction of measuring devices, analysis materials, instruments, etc., and can solve the problems of comparability and insufficient operation convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the embodiment of the square plate sample.

[0052] The sample material is an Al6061 aluminum alloy plate with a thickness of 0.8 mm, a yield strength of 188 MPa, an elastic modulus of 68900 MPa, and a Poisson's ratio of 0.4.

[0053] The sheet metal wrinkling performance test method based on the uniaxial tension of the sample with holes of the present invention, the specific steps are as follows:

[0054] (1) The side length dimension L of the square plate sample is 100mm;

[0055] (2) Determine the diameter d of the circular inner hole at the geometric center of the sample:

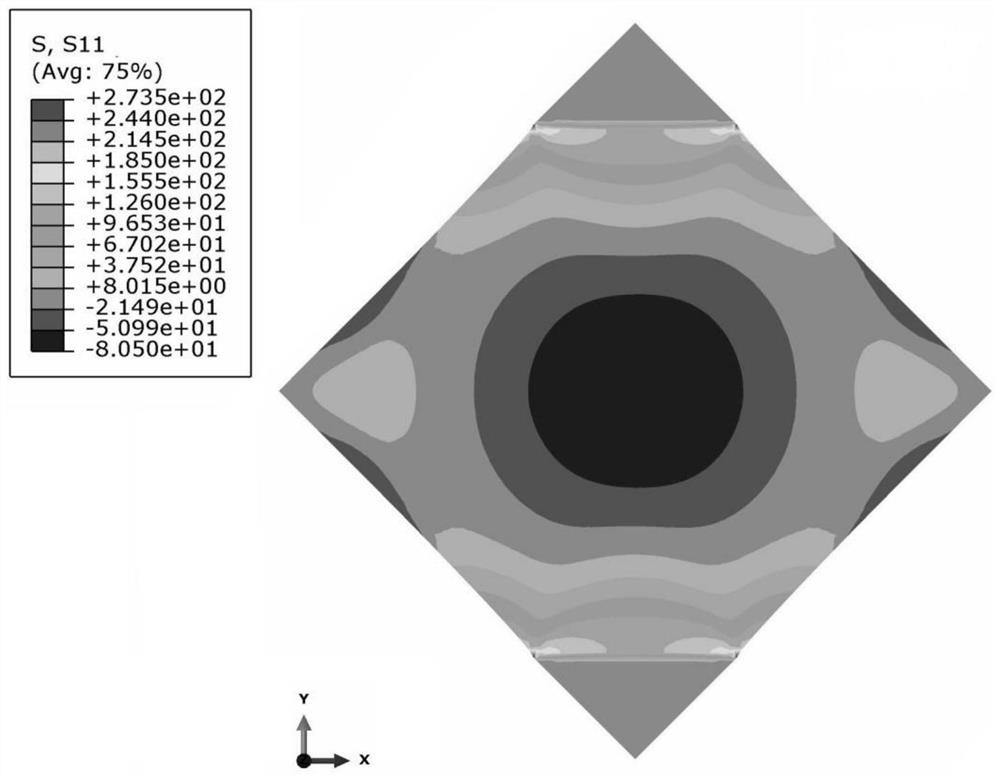

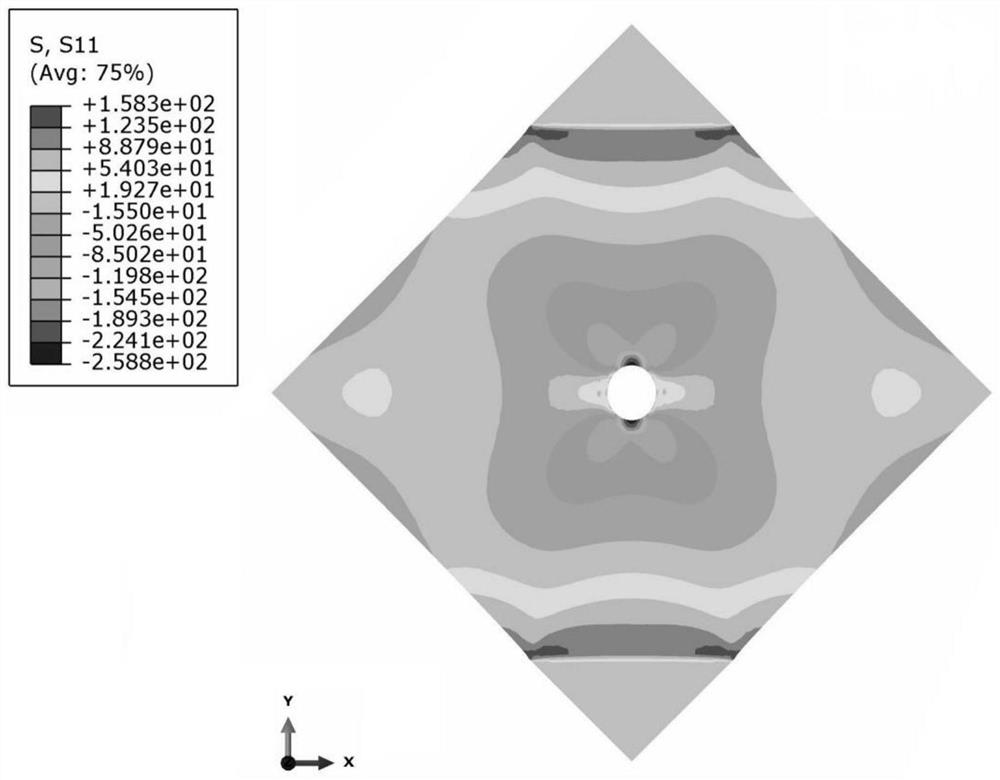

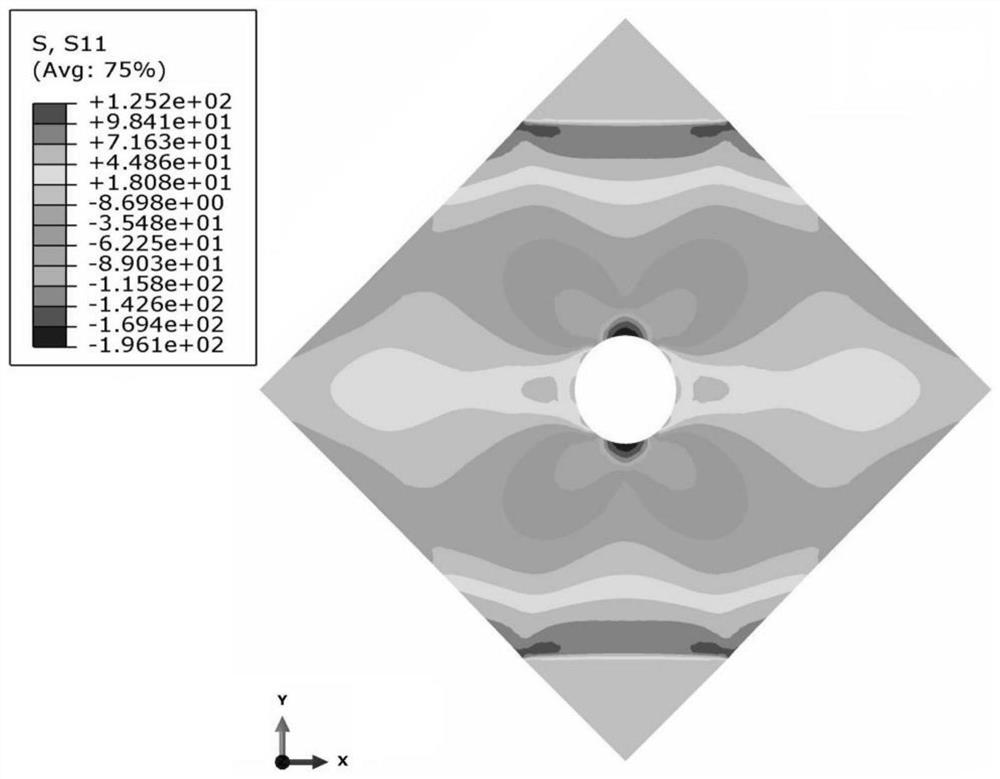

[0056] The finite element numerical simulation method is used to analyze the deformation of the sample during uniaxial tension, and to obtain the stress distribution and wrinkling state inside the sample; according to Figure 1-3 The X transverse compressive stress S of the simulated sample at the moment of wrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com