A collaborative method of multi-processing robots in hardware flexible production workshop

A production workshop, hardware flexible technology, applied in the direction of instruments, comprehensive factory control, comprehensive factory control, etc., can solve problems such as congestion, collision, various conflicts and failures in complex workshops, and improve the level of automation and flexibility. , avoid the effect of calculating the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will now be described in further detail with reference to the accompanying drawings.

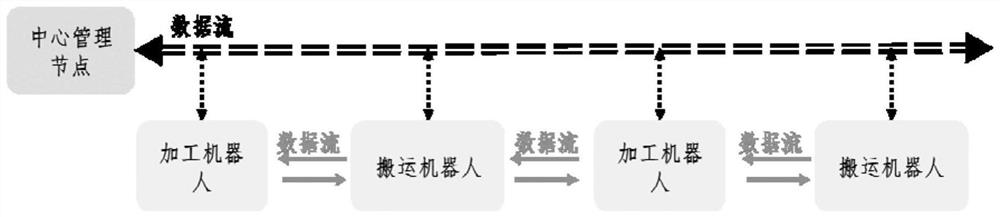

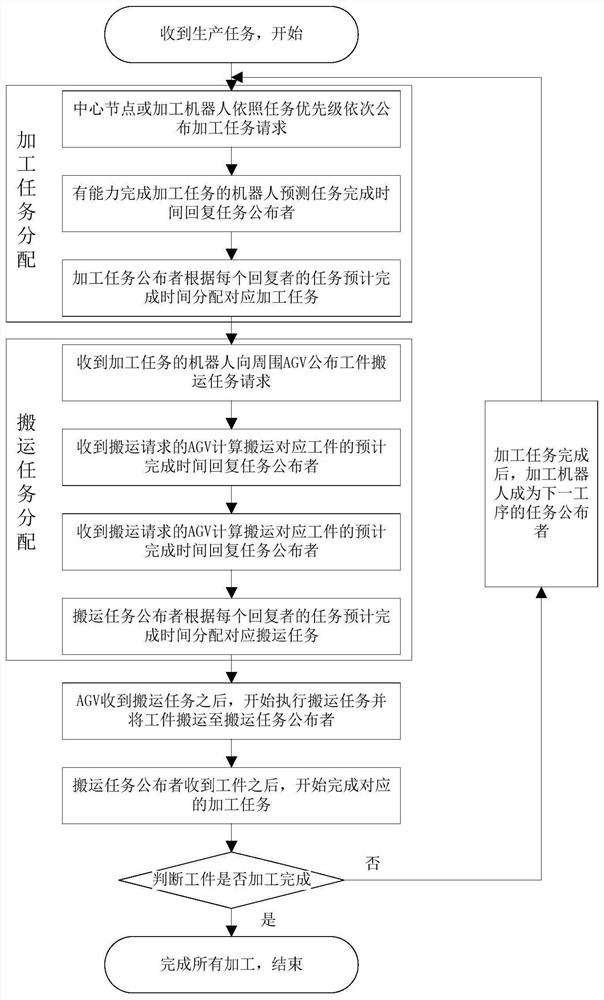

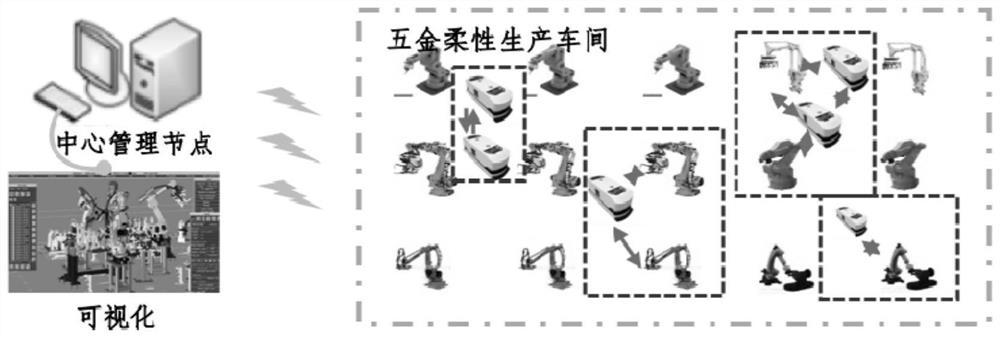

[0051] The multi-processing robot cooperation method of the hardware flexible workshop proposed by the present invention takes the processing robot as the main initiator of the main processing tasks and handling tasks in the workshop, and realizes the rapid assignment and execution of tasks through communication and cooperation with various surrounding processing robots; comprehensive application Distributed collaboration and centralized intervention and deployment methods solve various possible faults and congestion problems in the workshop, and improve the flexibility and automation level of the system. Specifically, the present invention will focus on a modular flexible production workshop including a variety of processing robots and AGVs, and study the distributed task allocation methods for the above-mentioned various processing robots. The application of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com