Soilless culture equipment capable of automatically planting agricultural hydroponic vegetables

A technology for hydroponic vegetables and soilless culture, applied in soilless culture, botanical equipment and methods, cultivation and other directions, can solve problems such as root growth obstruction, nutritional imbalance, plant death, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

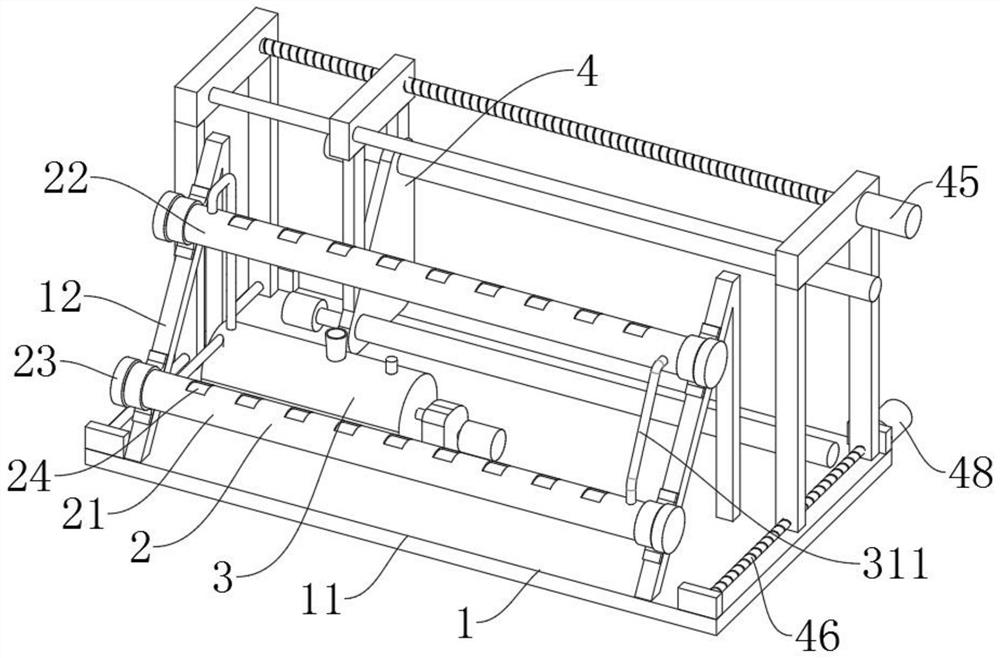

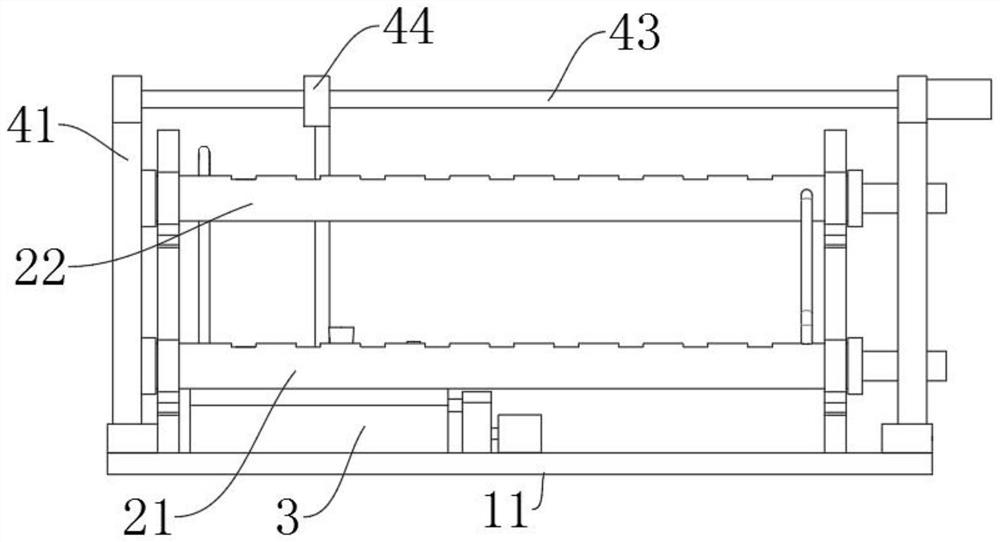

[0041] like Figure 1-Figure 7As shown, a soilless cultivation device capable of automatically planting agricultural hydroponic vegetables includes a support mechanism 1, a planting mechanism 2 is arranged on the support mechanism 1, a nutrient solution circulation mechanism 3 is arranged on the lower side of the planting mechanism 2, and the planting mechanism 2 The rear side is provided with a cleaning mechanism 4, the cleaning mechanism 4 is connected with the support mechanism 1, and the circulation mechanism 3 is connected with the planting mechanism 2;

[0042] The support mechanism 1 includes a base plate 11, the base plate 11 is provided with a support frame 12, the support frame 12 is welded to the base plate 11, and the support frame 12 is connected to the planting mechanism 2;

[0043] The planting mechanism 2 includes a lower planting tube 21 and an upper planting tube 22, and both ends of the lower planting tube 21 and the upper planting tube 22 are provided with ...

Embodiment 2

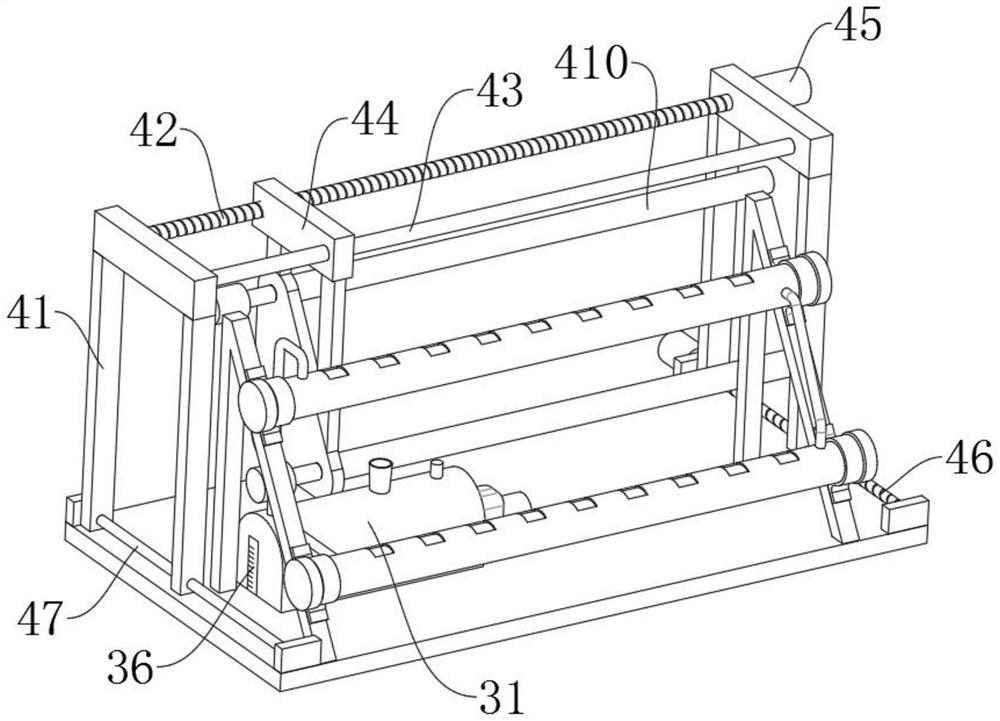

[0048] like Figure 1-Figure 6 , Figure 8 As shown, a soilless cultivation device capable of automatically planting agricultural hydroponic vegetables includes a support mechanism 1, a planting mechanism 2 is arranged on the support mechanism 1, a nutrient solution circulation mechanism 3 is arranged on the lower side of the planting mechanism 2, and the planting mechanism 2 The rear side is provided with a cleaning mechanism 4, the cleaning mechanism 4 is connected with the support mechanism 1, and the circulation mechanism 3 is connected with the planting mechanism 2;

[0049] The support mechanism 1 includes a base plate 11, the base plate 11 is provided with a support frame 12, the support frame 12 is welded to the base plate 11, and the support frame 12 is connected to the planting mechanism 2;

[0050] The planting mechanism 2 includes a lower planting tube 21 and an upper planting tube 22, and both ends of the lower planting tube 21 and the upper planting tube 22 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com