Agricultural peanut turnover, cleaning and beating-off device

A technology of flipping and cleaning peanuts, which is applied in agriculture, agricultural machinery and tools, and applications. It can solve the problems of insufficient cleaning, easy knocking of peanuts, and falling of peanuts, so as to improve safety, accuracy, and high work efficiency. , good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

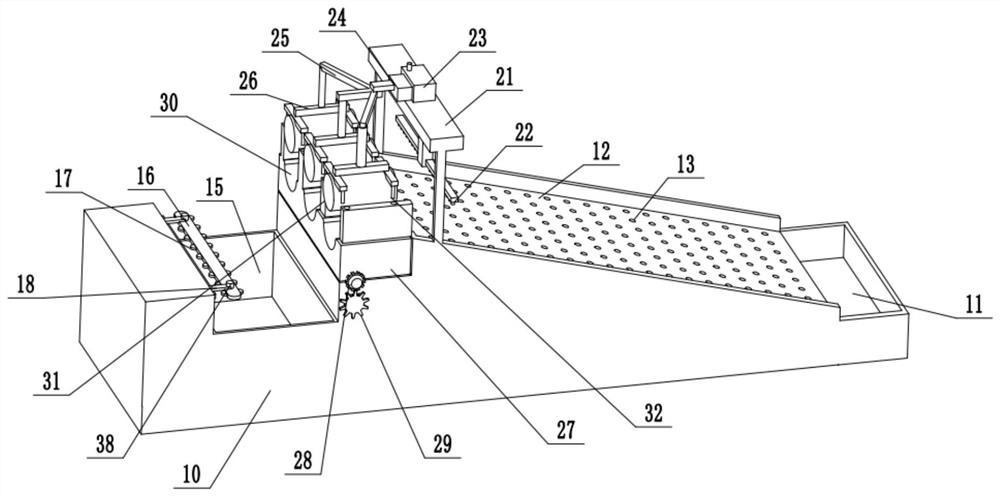

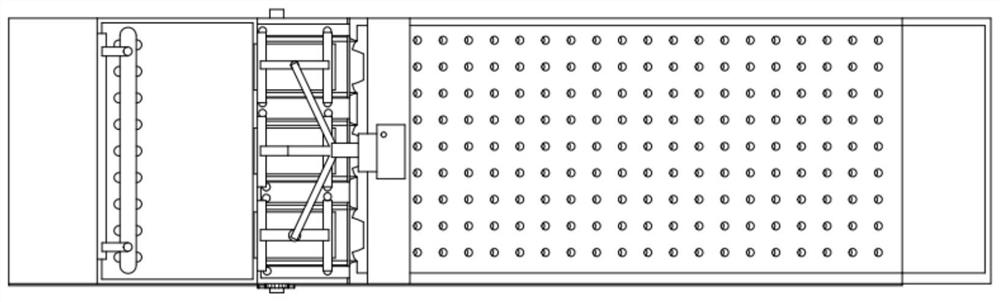

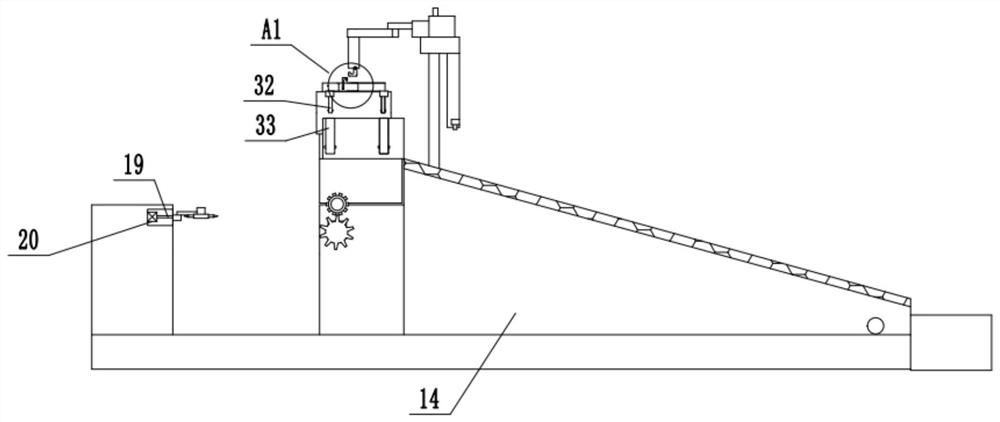

[0026] see Figure 1-4, a device for turning over, cleaning and knocking down peanuts for agriculture, comprising a base 10, a water spray row 22, and a cutting knife 17; the upper left side of the base 10 is provided with a group of second collecting tanks for storing the knocked-off peanuts downwards 15. On the top right side of the base 10, a set of blanking plates 12 with high left and low right are fixedly installed. The surface of the blanking plate 12 is provided with several sets of water filter holes 13 evenly distributed for filtering peanuts and muddy water. The bottom of the material plate 12 is communicated with a waste water chamber 14 arranged inside the base 10 , through which the muddy water from washing peanuts on the material plate 12 is collected. The bottom end of the blanking plate 12 is connected with a first collecting tank 11 fixed on the right end of the base 10 . The upper left side of the blanking plate 12 is fixedly installed with a group of top b...

Embodiment 2

[0029] On the basis of Embodiment 1, the inner surface of the peanut trough 30 and the outer surface of the pressure rod 31 are wrapped with a layer of rubber pads, which are used to prevent the two from contacting each other when the peanut branches and leaves are placed inside it. Large, the leaves are squeezed out of the water or the branches are broken, flowing and scattered randomly, which is not conducive to the safe operation of the equipment.

[0030] The working principle of the present invention is: when in use, first place the branches and leaves of the peanuts to be cleaned and knocked down inside the peanut trough 30, and place the fruit part under the water spray row 22 on the right side of the peanut trough 30, and then start the elevator 24 drives the pressing rod 31 connected to the bottom of the connecting frame 25 to move downwards, the branches and leaves of the peanuts are clamped and stabilized by the pressing rod 31 and the peanut groove 30, and then the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com