A kind of preparation method of slm type 3d printing cufe alloy

A 3D printing and alloy technology, which is applied in the field of SLM-type 3D printing CuFe alloy preparation, can solve the problems of difficult casting and processing, increase the preparation process, reduce production efficiency, etc., and achieve simple and easy-to-promote processing methods, simple heat treatment process, The effect of reducing printing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

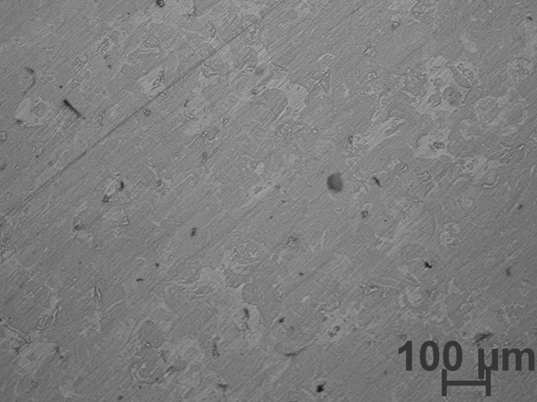

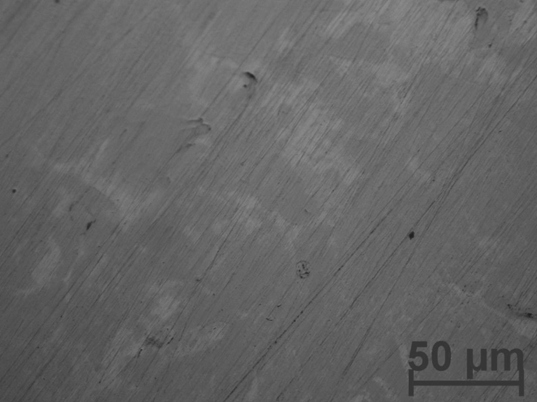

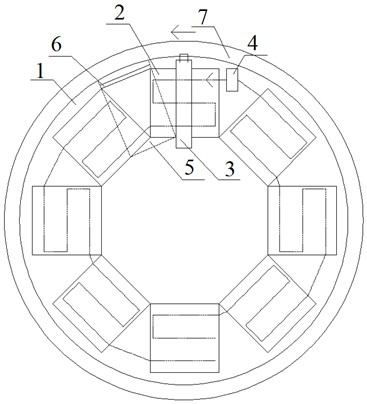

[0038] Such as Figure 5 Shown, a kind of SLM formula 3D prints CuFe alloy preparation method, comprises the following steps:

[0039] S1 ingredients: according to the composition requirements of the CuFe alloy material, select gas-atomized Cu powder: 60wt%, particle size 40μm; Fe powder: 40wt%, particle size 50μm; put the weighed gas-atomized Cu powder and Fe powder into the atmosphere In the protected ball mill, vacuumize to less than 10 -1 Pa, then fill it with hydrogen to 0.8MPa; then start ball milling, the ball-to-material ratio is 1:5, the ball milling time is 5 hours, and the sphericity is 95%.

[0040]S2 SLM3D printing: put the mixed CuFe powder into the powder bin of the 3D printing equipment, and use an ice shovel to tamp it for later use, prepare the 3D model of the required workpiece through the computer, the workpiece is a mechanical part, and connect the 3D printer to the computer , and processed according to the three-dimensional model, the processing method ...

Embodiment 2

[0047] This embodiment is basically the same as Embodiment 1, the difference is:

[0048] S1 ingredients: according to the composition requirements of the CuFe alloy material, select gas atomized Cu powder: 35wt%, Fe powder: 65wt%.

Embodiment 3

[0050] This embodiment is basically the same as Embodiment 1, the difference is:

[0051] S1 ingredients: according to the composition requirements of the CuFe alloy material, select gas atomized Cu powder: 20wt%, Fe powder: 80wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com