Test bed detecting reliability of stud tensioner and detection method thereof

A test bench and tensile machine technology, applied in the testing of mechanical components, the testing of machine/structural components, and the use of stable tension/pressure to test the strength of materials, etc., can solve problems such as failure to verify the performance of bolt tensile machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and embodiment the present invention is further introduced:

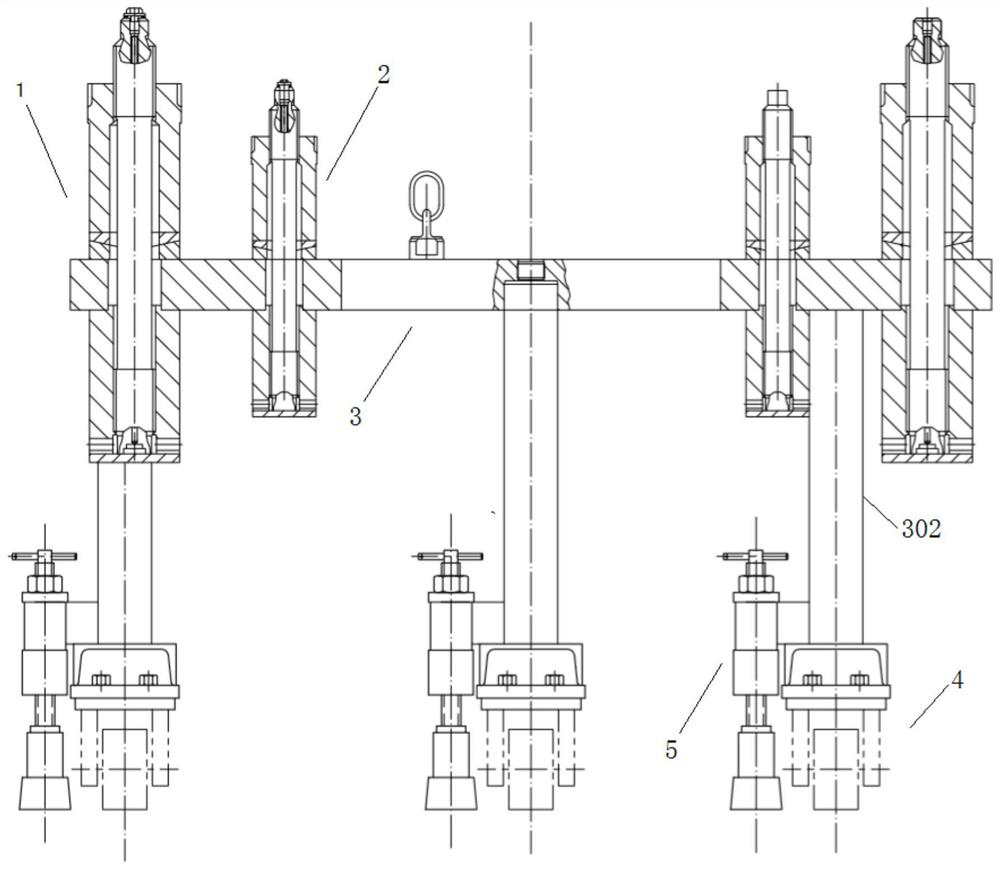

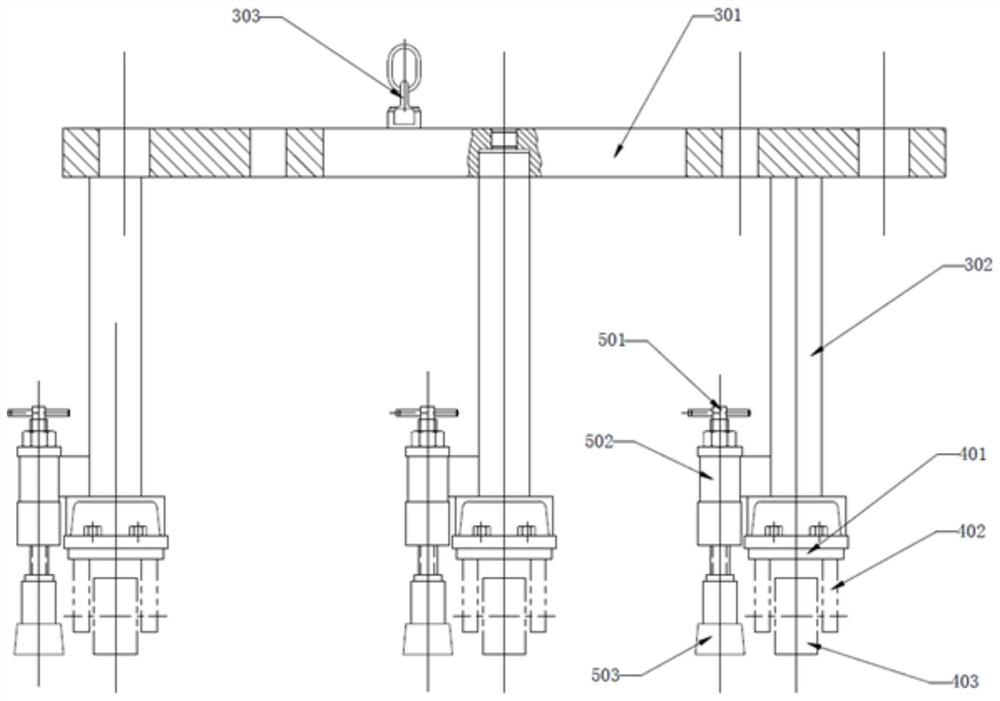

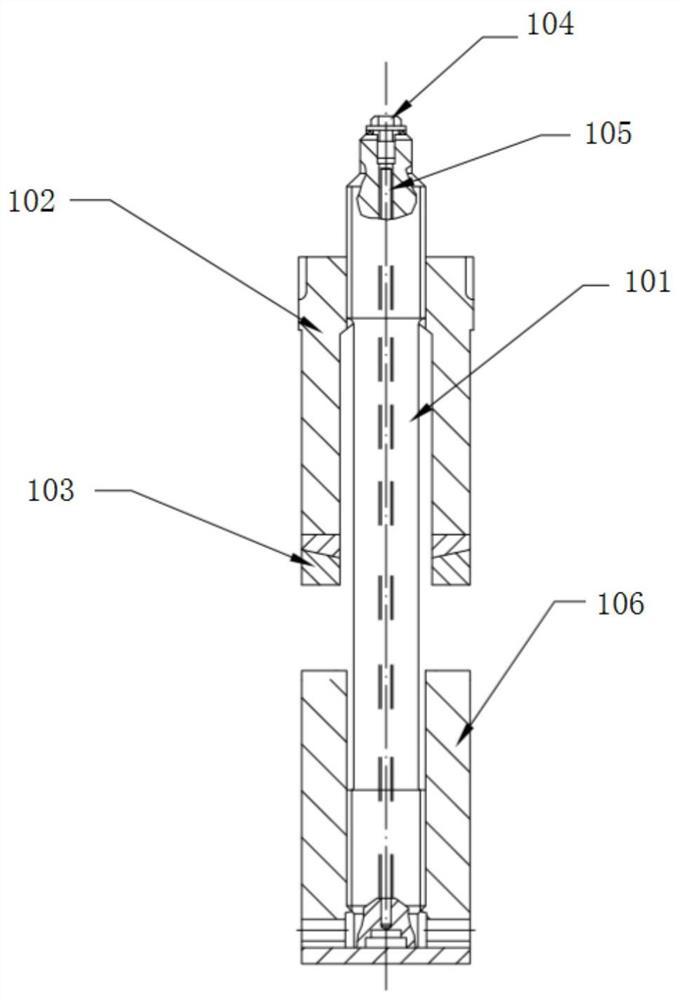

[0041] A test bench for testing the reliability of a bolt tensioning machine, comprising:

[0042]Several primary circuit top cover bolt assemblies 1, several secondary circuit top cover bolt assemblies 2, platform board 301, several support rods 302, several lifting lugs 303, several roller assemblies 4 and support foot assemblies 5; The lower surface of the platform board 301 is fixedly connected with several support rods 302, and the upper surface of the platform board 301 is evenly provided with several threaded through holes; each support rod 302 is provided with a roller assembly 4 and a support A foot assembly 5; the roller assembly 4 is fixedly connected to the supporting foot assembly 5;

[0043] The plurality of primary circuit top cover bolt assemblies 1 and the plurality of secondary circuit top cover bolt assemblies 2 are respectively fixed on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com