Stacking device, loading machine and loading method

A loading machine and stacking technology, applied in the direction of conveyor control devices, loading/unloading, conveyor objects, etc., can solve the problem of high loading accuracy, box-type goods that cannot be squeezed and deformed, and loading in narrow stacking spaces Equipment operations and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

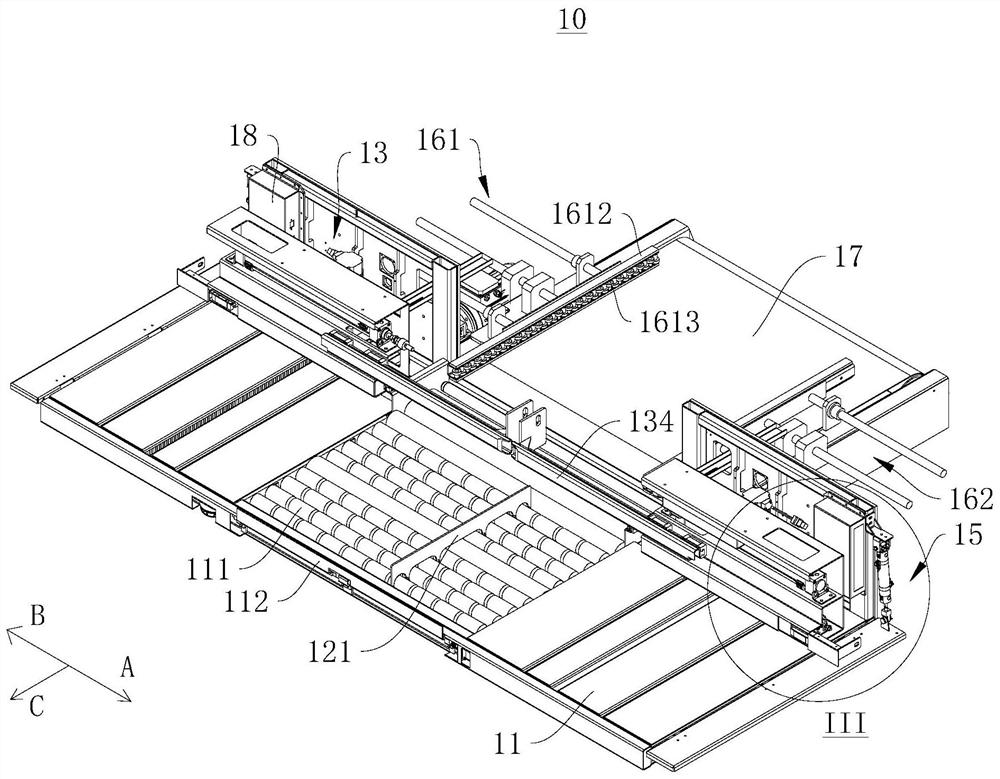

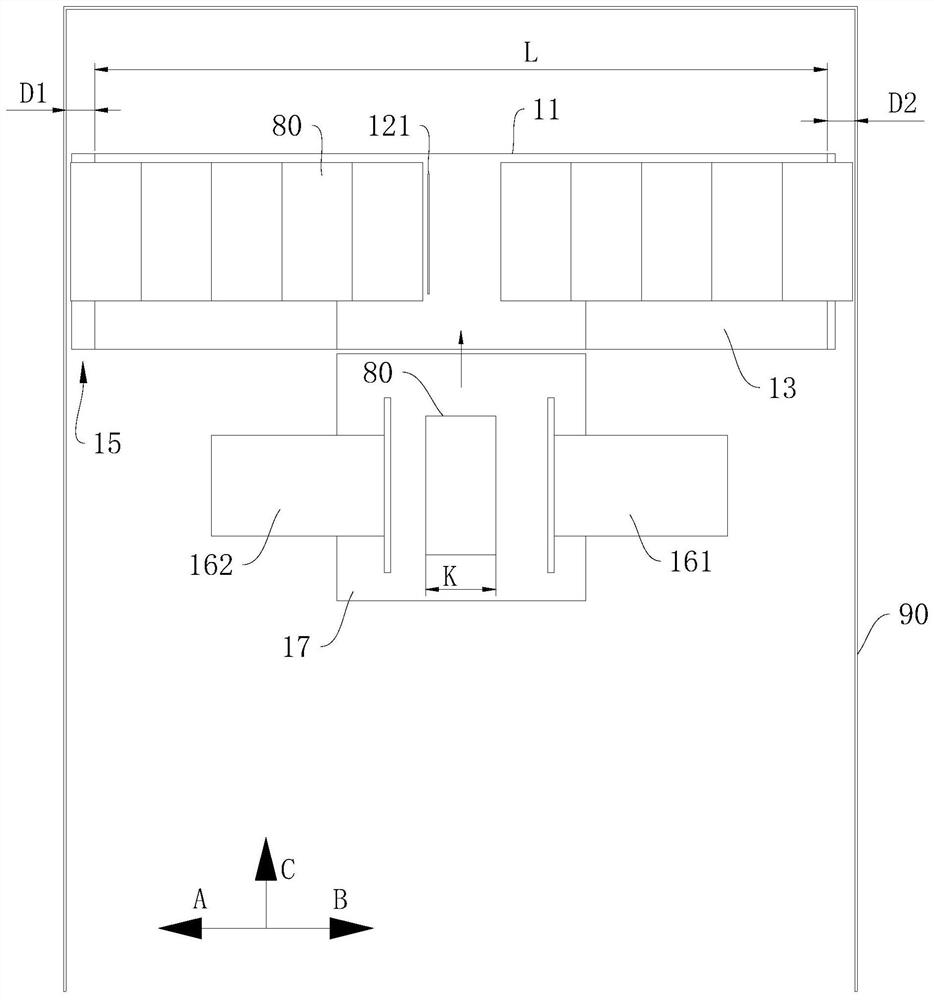

[0037] see figure 1 , figure 1 It is a schematic diagram of the three-dimensional structure of the stacking device 10 provided by the first embodiment of the present invention. figure 1 Among them, the direction indicated by the arrow A is the first direction A, the direction indicated by the arrow B is the second direction B, and the direction indicated by the arrow C is the third direction C.

[0038] The first embodiment of the present invention provides a stacking device 10 , the stacking device 10 has the characteristics of high utilization rate of the space of the compartment 90 and is not easy to squeeze the goods 80 . The stacking device 10 can be applied to a vehicle loading machine 100, a vehicle loading system, a logistics storage system, and the like.

[0039] The structural composition, working principle and beneficial effects of the stacking device 10 provided by the first embodiment of the present invention will be described in detail below.

[0040] see fig...

no. 2 example

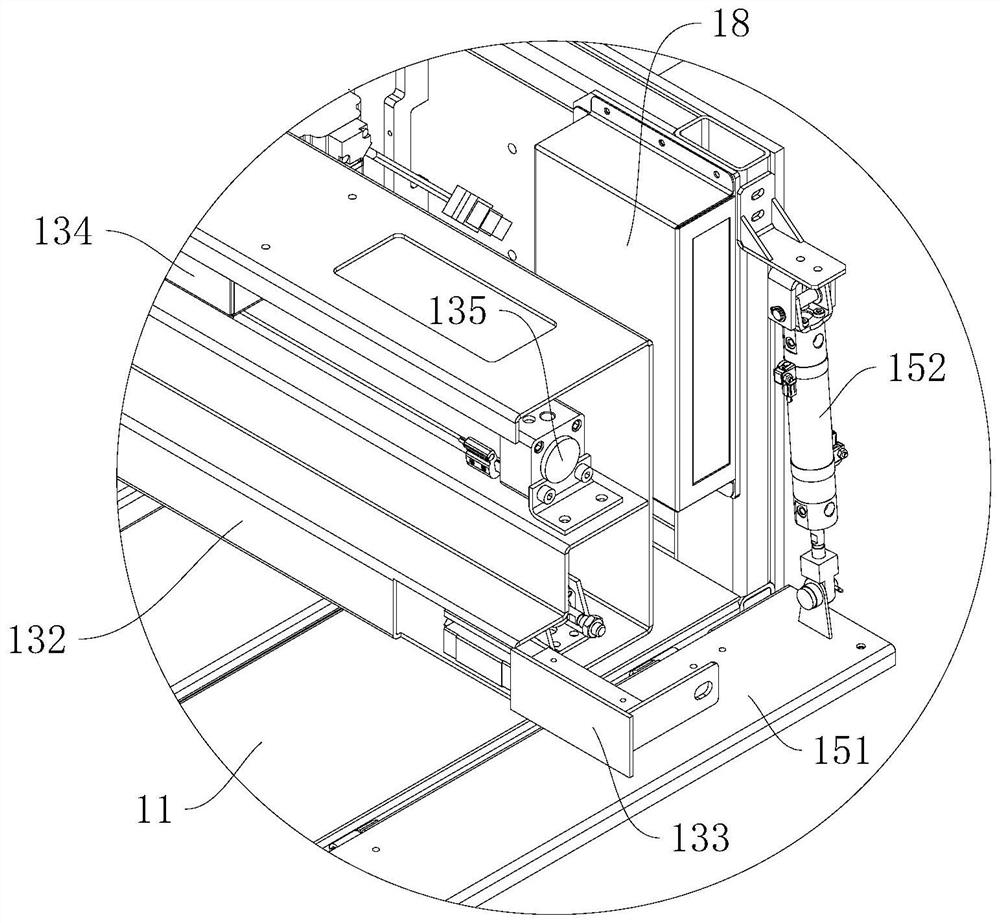

[0085] see Figure 4 , Figure 5 and Image 6 , Figure 4 It is a schematic perspective view of the three-dimensional structure of the vehicle loading machine 100 provided in the second embodiment of the present invention. Figure 5 It is a schematic diagram of the side structure of the vehicle loading machine 100 provided in the second embodiment of the present invention. Image 6 It is a three-dimensional schematic diagram of the connection between the cargo conveying line 20 of the vehicle loader 100 and the stacking device 10 provided by the second embodiment of the present invention.

[0086] The second embodiment of the present invention provides a vehicle loading machine 100. The vehicle loading machine 100 adopts the stacking device 10 provided by the first embodiment of the present invention. The vehicle loading machine 100 also has a compartment 90 with a high space utilization rate and is not easy to squeeze. Features of Press Cargo 80. The vehicle loading mach...

no. 3 example

[0094] see Figure 7 , Figure 7 It is a schematic flowchart of the loading method provided by the third embodiment of the present invention.

[0095] The third embodiment of the present invention provides a vehicle loading method, which is applied to the stacking device 10 or the vehicle loading machine 100 mentioned in the above embodiments, which also has a high space utilization rate of the compartment 90 and is not easy to squeeze Cargo 80 features.

[0096] It should be noted that the basic principles and technical effects of the loading method provided in this embodiment are the same as those of the above-mentioned embodiment. For a brief description, the part not mentioned in this embodiment can refer to Corresponding content.

[0097] The loading method includes:

[0098] Step S101: Move the cargo 80 along the first direction A or the second direction B according to the horizontal position data and the preset stacking data, so that both ends of the row of cargo 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com