Cloth winding machine for clothing processing and production

A cloth and clothing technology, applied in the field of cloth winding machinery for garment processing and production, can solve the problems of easy loosening of the winding cloth, reducing the practicality of the winding machinery, and reducing the convenience of the cloth winding drum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

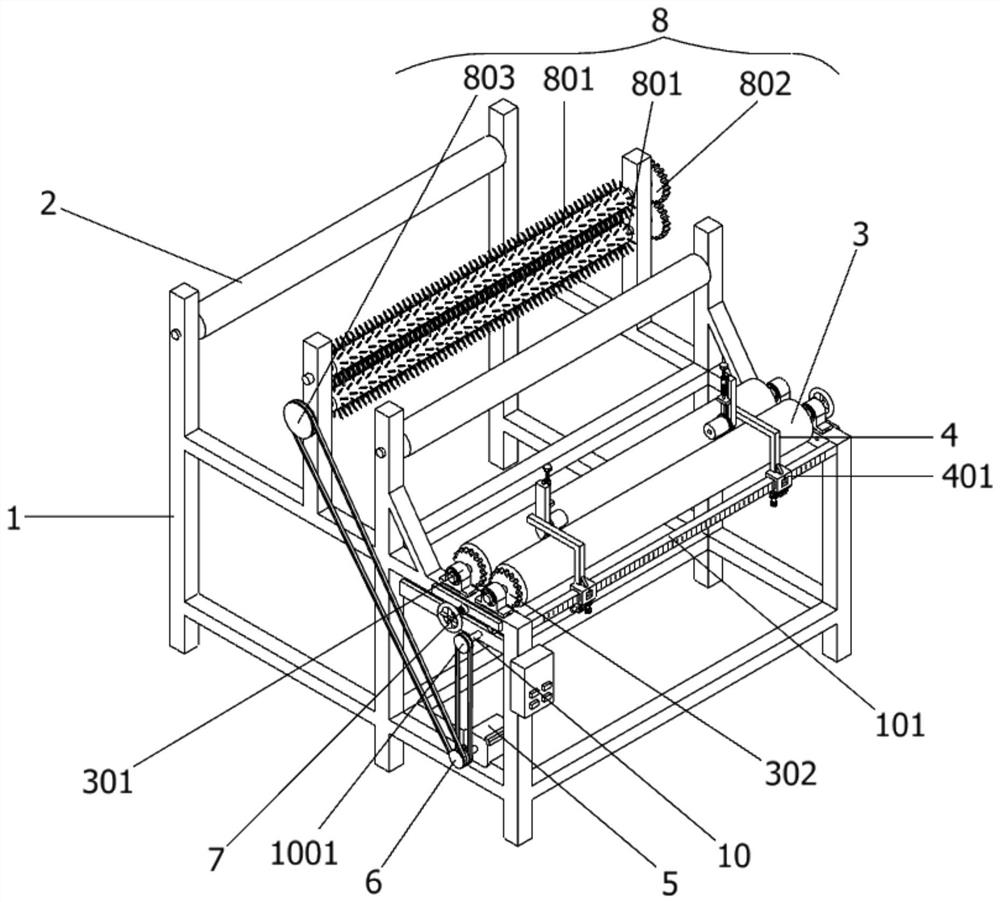

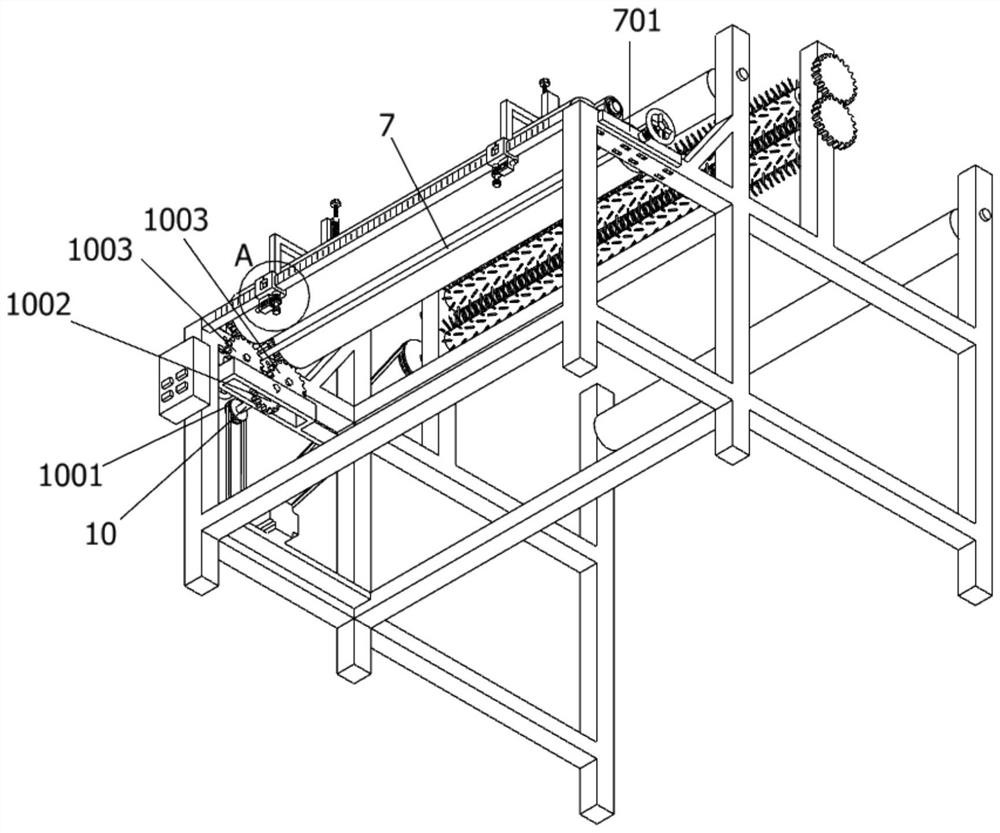

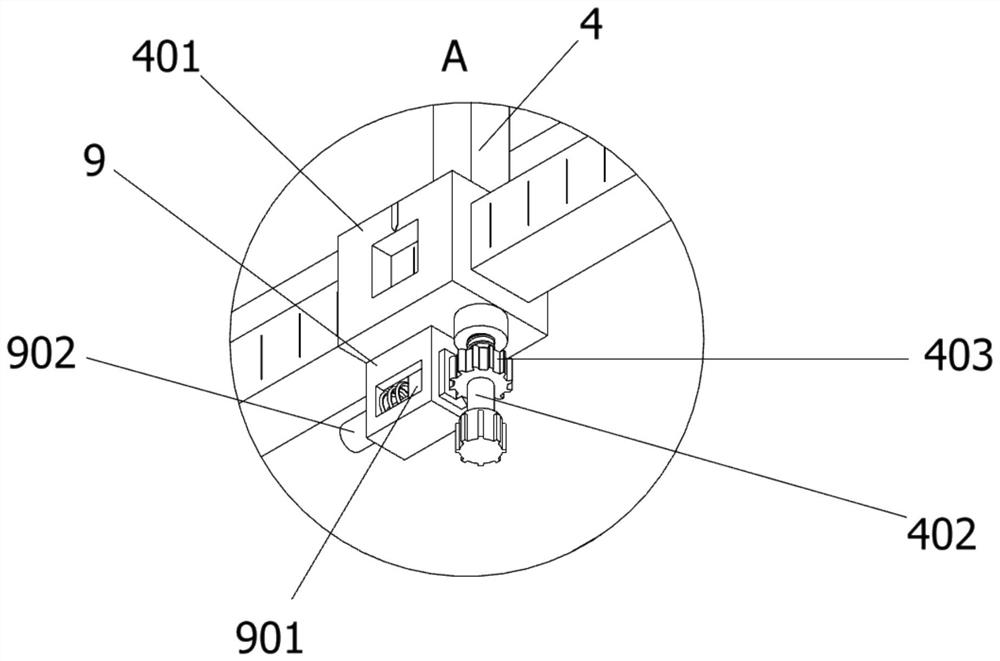

[0033] as attached figure 1 To attach Figure 8 Shown:

[0034] The present invention provides a cloth winding machine for garment processing and production, which includes: a frame 1, the upper part of the rear side of the frame 1 is connected with two transmission rollers 2 through rotating shafts, and the frame 1 includes a square slide bar 101 and a rectangular socket 102 And circular jack 103, frame 1 front side upper part is provided with square slide bar 101, and square slide bar 101 front end faces are provided with size markings, frame 1 front end left and right sides two support top ends are uniform shape and are provided with eight A rectangular socket 102, and the upper part of the opposite sides of the two brackets at the front end of the frame 1 are provided with four circular sockets 103 communicating with the rectangular socket 102; Mechanism 8, cleaning mechanism 8 comprises roller brush 801, second gear 802 and driven pulley 803, the quantity of roller brus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com