Laser full-cutting machine for ultra-thin glass optical filter

A technology of ultra-thin glass and optical filter, which is applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., and can solve problems such as glass is easily pushed and shifted, glass filter is damaged, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

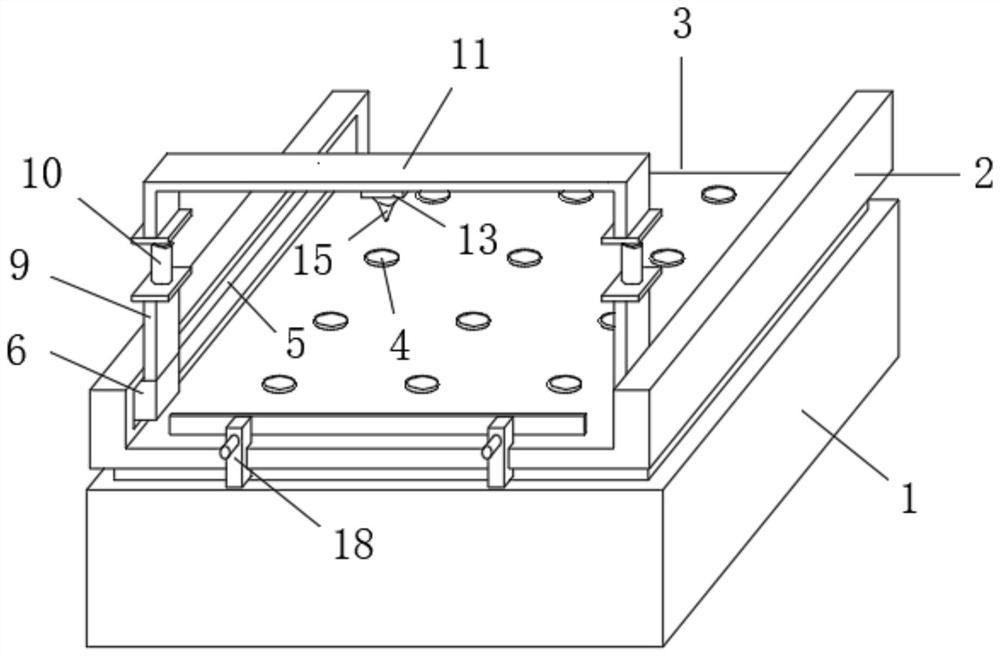

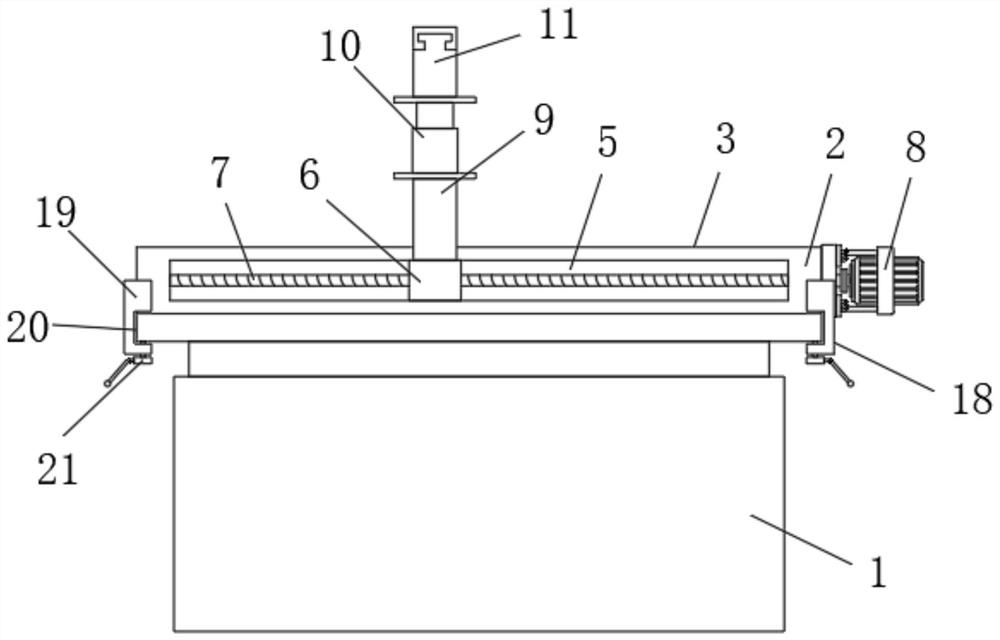

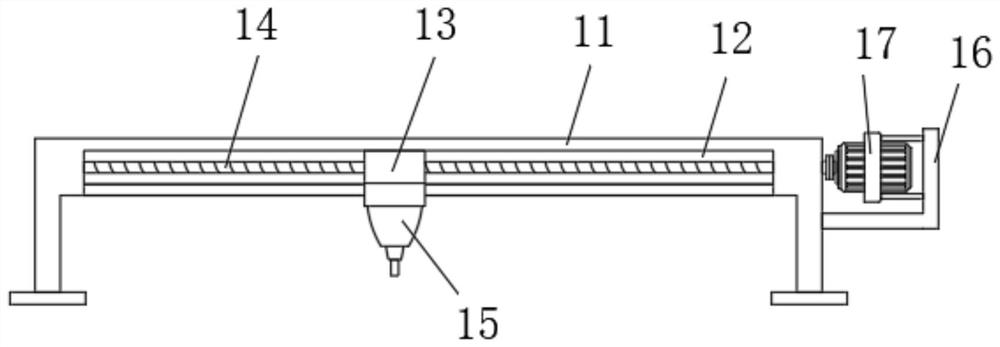

[0021] Such as Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: a kind of ultra-thin glass filter laser cutting machine, including a cutting machine base 1, the top of the cutting machine base 1 is fixedly connected with a cutting table 2, and the cutting table The middle part of the top of the top 2 is excavated with a glass storage tank 3, and the bottom of the glass storage tank 3 is equidistantly fixedly connected with a number of vacuum suction cups 4, and the opposite sides of the glass storage tank 3 are symmetrically excavated with two No. 1 suction cups. Chute 5, the inside of two described No. 1 chute 5s is all slidably connected with No. 1 slide block 6, and the top of described No. 1 slide block 6 is positioned at the outer end of No. 1 chute 5 and is all fixedly connected with support bar 9, two A horizontal plate 11 is connected between the tops of the two support rods 9, and the bottom of the horizontal plate 11 is excavat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap