Method for changing effective output length of combing machine

An effective output and combing machine technology, which is applied in the direction of combing machines, textiles and papermaking, fiber processing, etc., can solve the problem of heavy shadowing of overlapping joints, straightening of fibers, insufficient parallelism and separation, and affecting the quality of yarn products, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The method that a kind of combing machine of the present invention changes effective output length is further described below in conjunction with specific embodiment:

[0022] A method for changing the effective output length of a comber of the present invention comprises the following steps:

[0023] A combing machine is provided, and the combing machine has a transmission mechanism to be changed;

[0024] The differential gear Z1 in the outer differential gear train consists of 43 T changed to 48 T , Z4 by 48 T changed to 49 T ;The modulus of planetary gear Z2 is changed from 3.25 to 3.0, and the number of teeth remains unchanged (17 T ), the planetary gear Z3 consists of 17 T Change to 16 T , the modulus remains unchanged (3.0); each set of differential gear train needs to process 48 T 1 gear, 49 T 1, 16 T 3, 17 T 3 pieces, a total of 8 gears, other gears and accessories can be slightly processed for use;

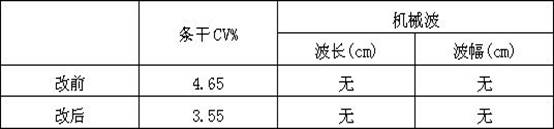

[0025] The effective output length of the separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com