Composite bridge expansion joint device

An expansion joint and composite technology, applied in the field of expansion joints, can solve the problems of troublesome operation, low connection tightness and long construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

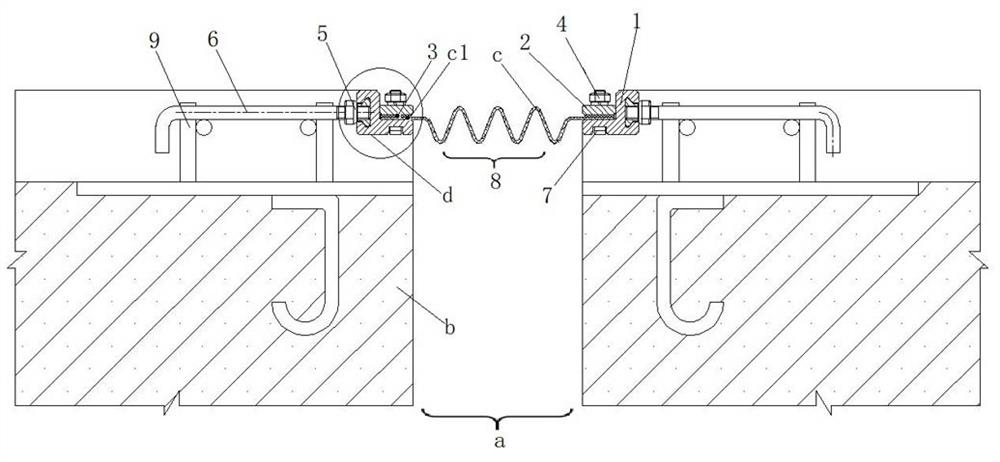

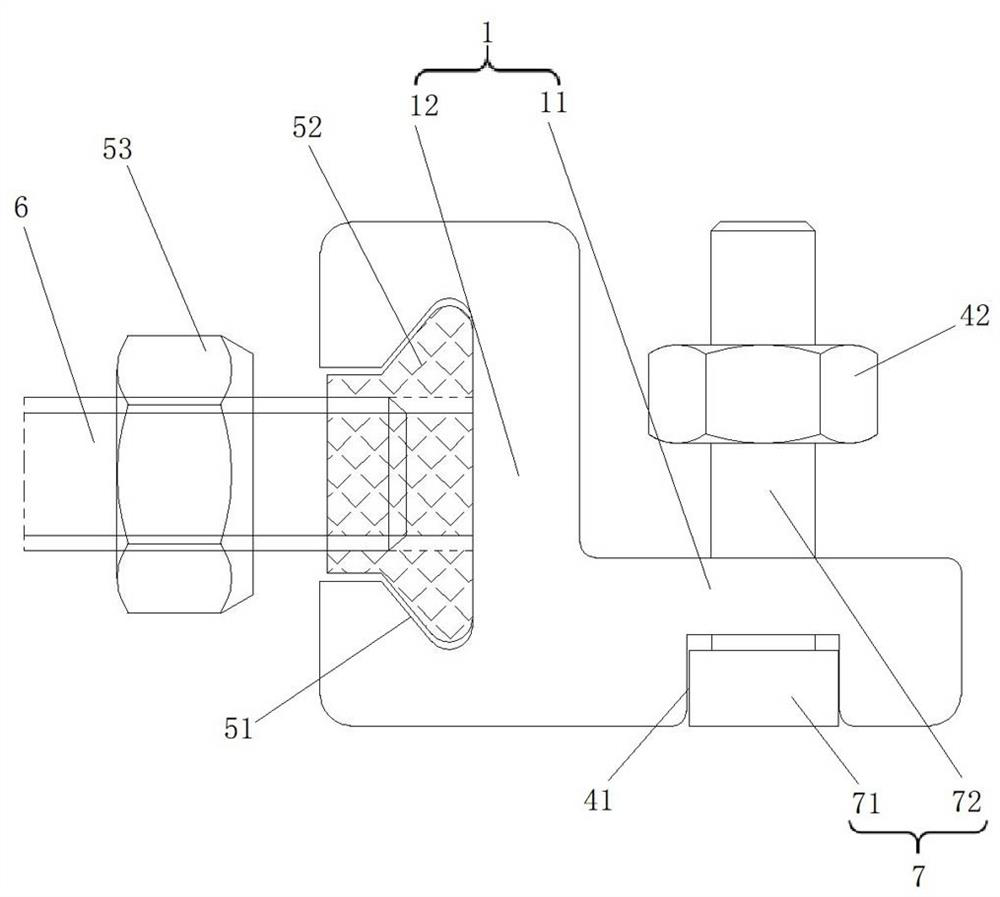

[0018] see figure 1 , figure 2 , is a structural schematic diagram of a composite bridge expansion joint device provided by the present invention. The structure of the composite bridge expansion joint device includes L-shaped steel 1 symmetrically arranged in the beam body b on both sides of the expansion joint a, the flat plate 11 of the L-shaped steel 1 is combined with the pressure plate 2 on it, and the water-stop belt c side ear straps c1 is sealed and fixed, the fastening bolt 7 runs through the pressure plate 2, the ear strap c1 and the plate 11 and locks the pressure plate 2 on the plate 11 through the first limit mechanism 4, between the pressure plate 2 and the ear strap c1 and / or between the ear strap c1 and the An elastic gasket 3 is arranged between the plates 11; the vertical plate 12 of the L-shaped steel 1 fits with the side wall of the reserved notch d of the beam body b, and the outer side of the vertical plate 12 is connected with the anchoring steel bar 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com