Immersed tube tunnel and construction method

The technology of an immersed tube tunnel and a construction method is applied in the field of construction engineering and can solve the problems of increasing the production and installation costs of immersed tubes and the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0052] The invention proposes an immersed tube tunnel.

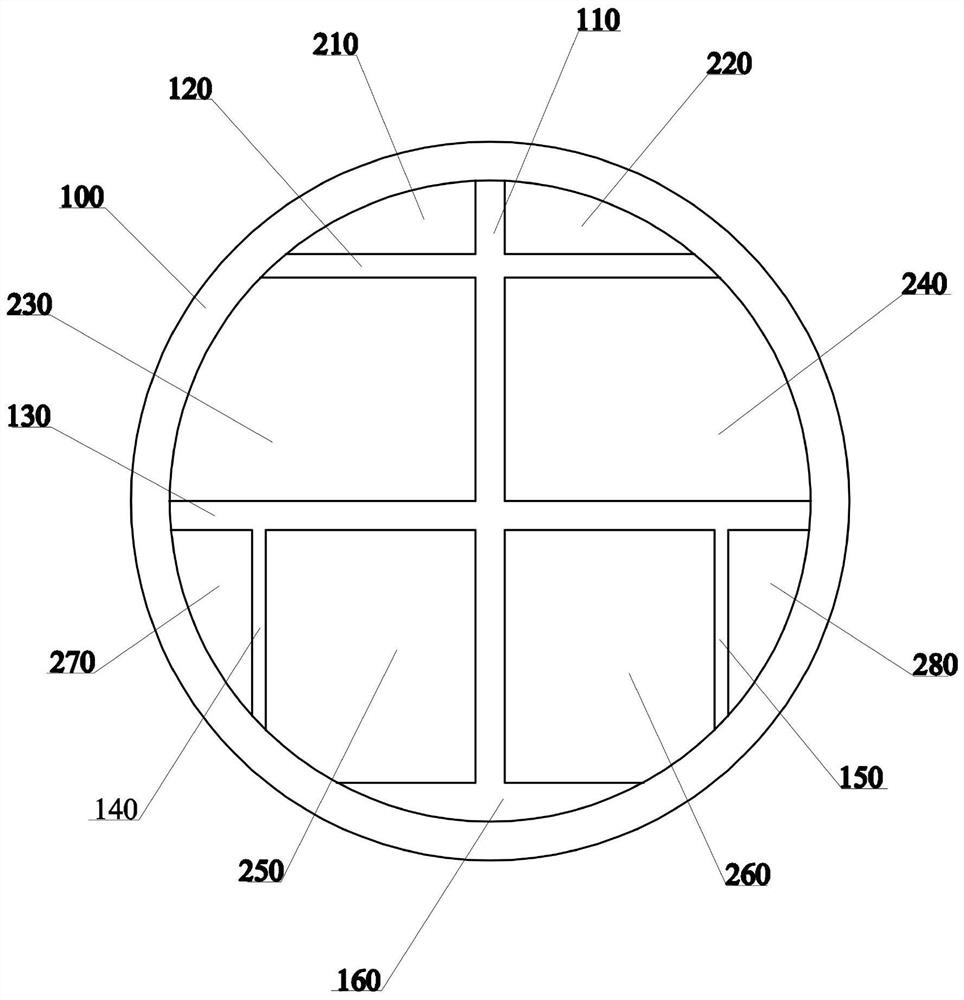

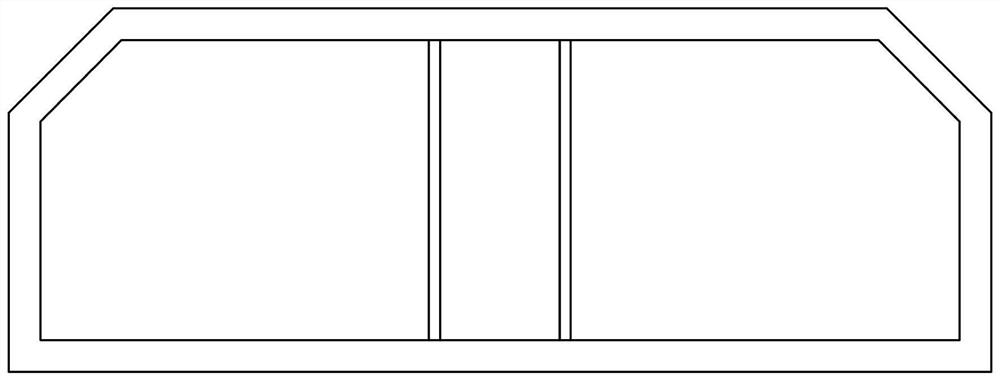

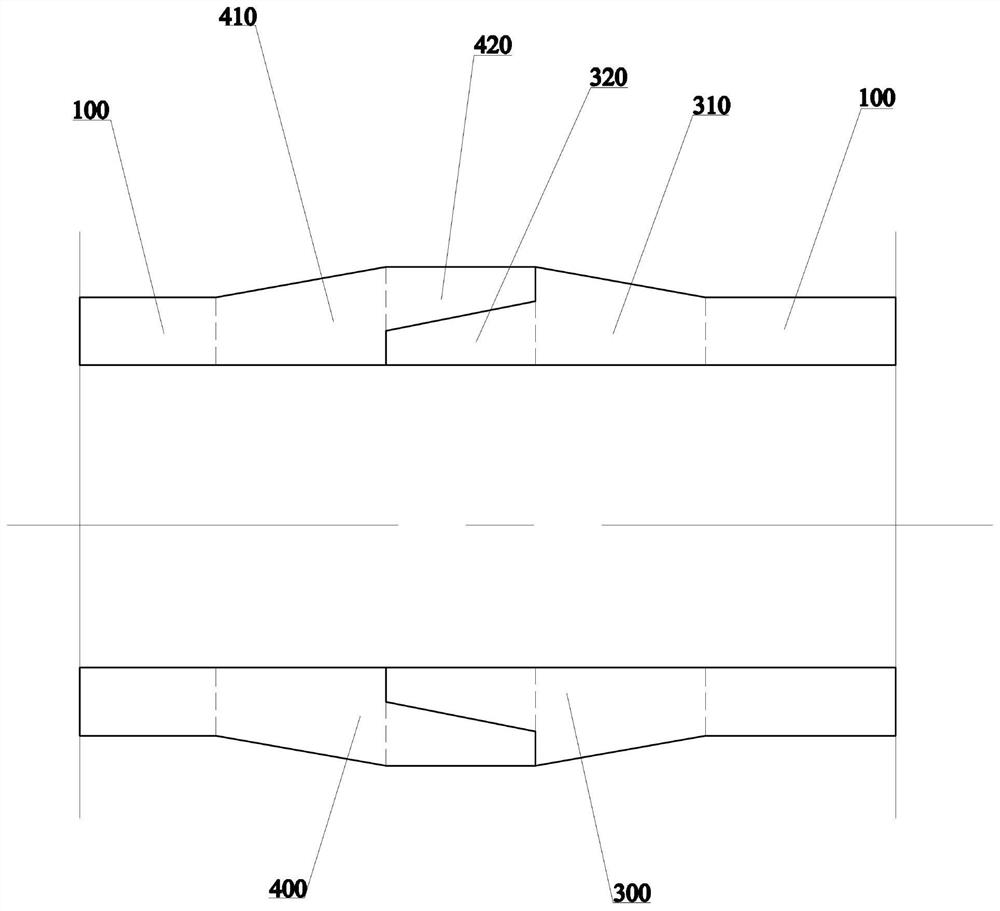

[0053] Such as figure 1 As shown, in an embodiment of an immersed tube tunnel proposed by the present invention, the immersed tube tunnel includes a cylinder body, that is, the immersed tube tunnel is formed by butting ends of a plurality of cylinder bodies, and the shape of the cylinder body is cylindrical The cylinder body includes a cylinder wall 100, a first rib 110, a second rib 120, a third rib 130, a fourth rib 140, and a fifth rib 150; both ends of the first rib 110 are connected to the cylinder The inner wall of the wall 100 and the central axis of the cylinder are located on the plane where the first rib 110 is located, that is, the first rib 110 is coplanar with the longitudinal section of the cylinder, that is, the first rib 110 divides the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com