Multifunctional feeder for poultry

A multi-functional, feeder technology, applied in the poultry industry, application, animal husbandry and other directions, can solve the problems of unreasonable feeding methods, easy to cause poultry diseases, uneven feeding, etc., and achieves low production and installation costs. The effect of reducing disease transmission routes and avoiding feed waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

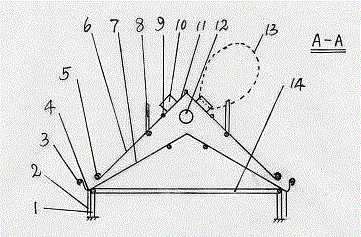

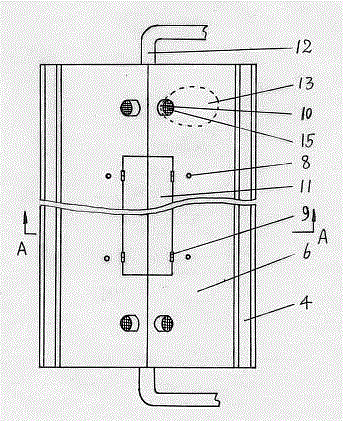

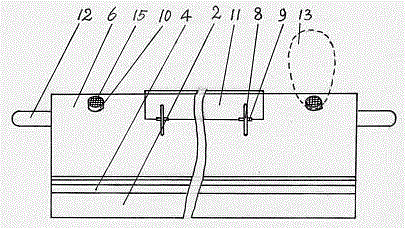

[0030] Such as Figure 1-3 As shown, the skeleton 14 is generally made of thick steel bars with a diameter of 8-12mm, and the basic components comprising the braces, longitudinal beams, etc. that form the skeleton are welded as a whole. Four parallel reinforcing bars are specially welded on the skeleton as the internal reinforcement 5 and the external reinforcement 3 of the groove, and the four reinforcing bars are arranged symmetrically, with two on one side. The triangular base plate 7 is made of galvanized sheet or stainless steel plate in one piece, and is folded at the center line to become the top line. The pecking groove 4 is formed by bending the two sides of the triangular base plate, and finally rolled on the outer rib of the groove to fix. The apex angle of the triangular bottom plate can be set according to specific requirements, in this example it is 120 degrees.

[0031] The triangular top plate 6 is made of the same material as the triangular bottom plate, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com