Labyrinth sealing device for improved drainage

一种迷宫式密封、密封装置的技术,应用在发动机的密封、运输和包装、旋转运动的轴承等方向,能够解决无法管理轴承单元轴向外侧等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

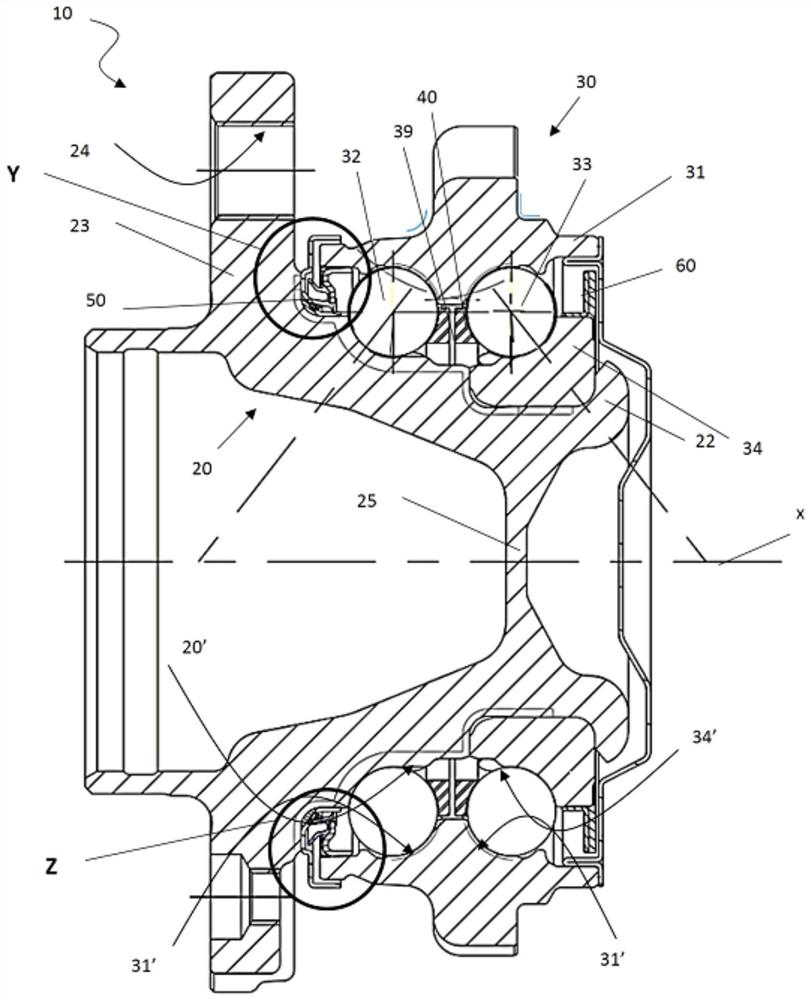

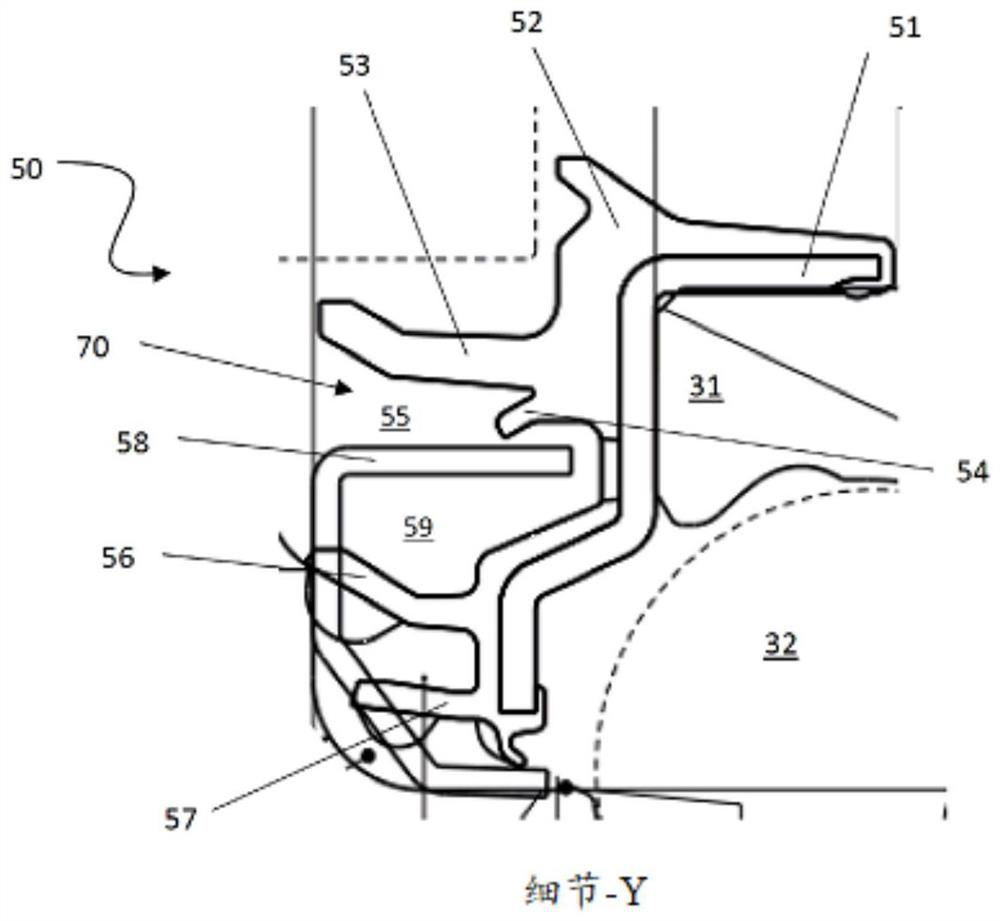

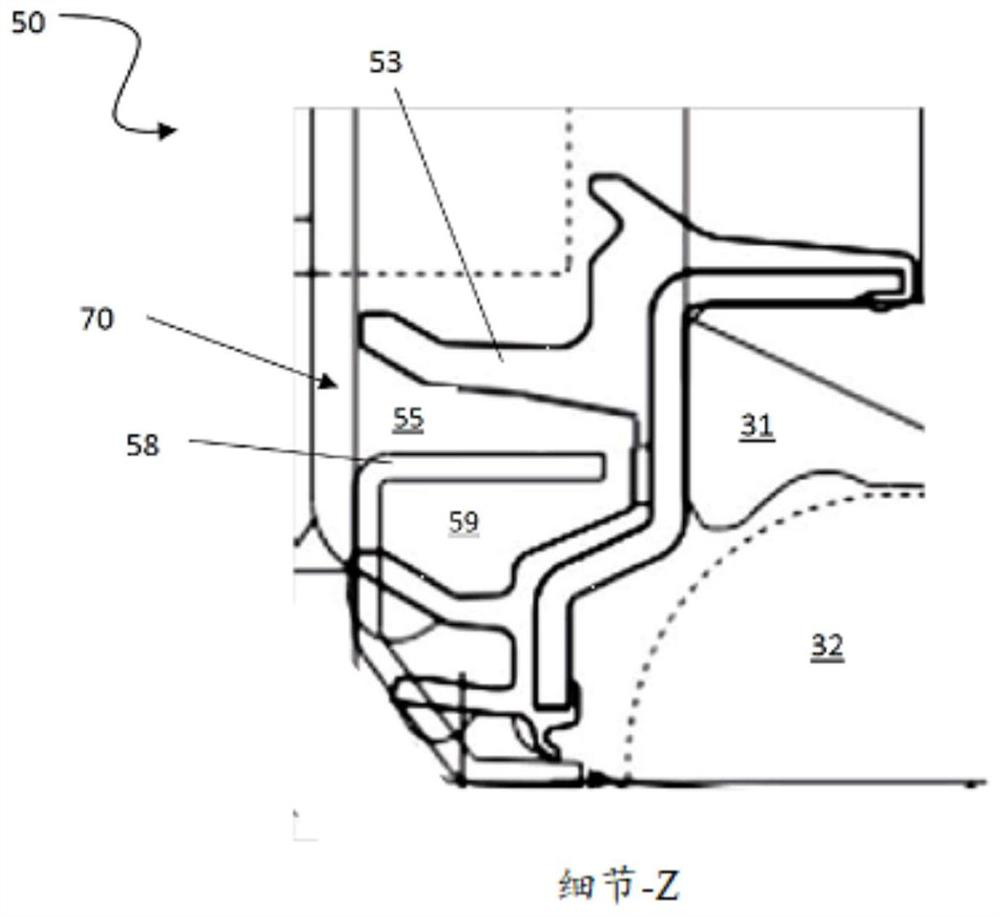

[0018] Now, purely by way of non-limiting example, the invention will be described with reference to a wheel hub assembly for a motor vehicle provided with a bearing unit having a sealing arrangement according to the invention.

[0019] refer to figure 1 , a wheel hub assembly according to a preferred embodiment of the present invention is indicated generally by 10 . The drawings show details of construction provided by way of example.

[0020] The assembly 10 has a central axis of rotation X and comprises a rotating hub 20 and a bearing unit 30 which in turn comprises:

[0021] - a stationary radial outer ring 31;

[0022] - a radially inner ring 22 defined by the hub 20;

[0023] - another radially inner ring 34 of rotation, mounted on and integral with the hub 20;

[0024] - two rows of rolling bodies 32, 33 arranged between the radially outer ring 31 and the radially inner ring 22, 34, rolling bodies 32, 33 being balls in this example; and

[0025] - Two cages 39 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com