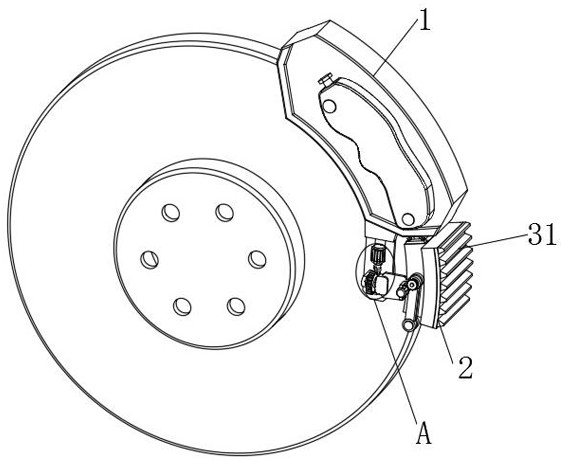

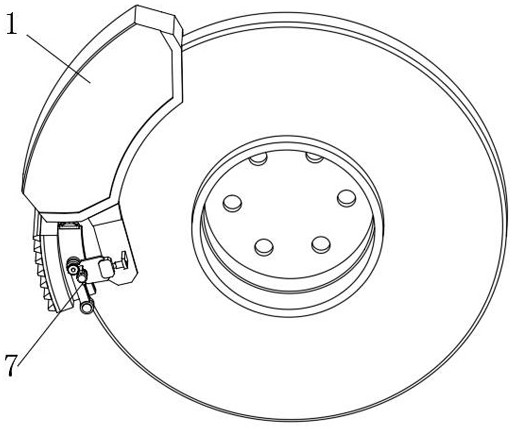

Air pressure disc brake

A disc brake and brake technology, applied in the direction of brakes, brake types, brake components, etc., can solve the problems of vehicle tires losing grip, hidden safety hazards of pneumatic disc brakes, and the ability of vehicles to lose control of the direction, etc., to achieve increased The effect of contact friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

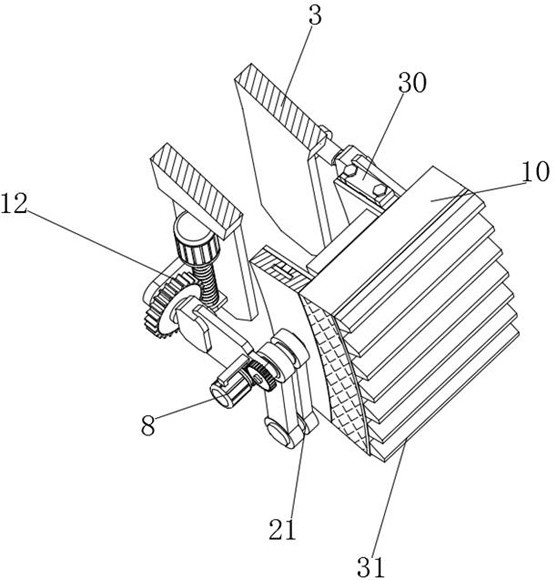

[0034] DETAILED DESCRIPTION: When the wheels are running on a normal ground, the two protective plates 9 are distributed on the outside of the brake disc, and the oil suction pad 29 plays a role of degreasing and dustproofing the brake disc. When the vehicle is freezing When driving on the road and braking, the driver judges the icy road subjectively according to the driving state, and controls the driving motor 16 to rotate through the in-vehicle controller, so that the driving gear 17 drives the driven gear 18 to rotate, and the driving gear 17 performs While rotating, the driving force of the support shaft 19 is provided. The support shaft 19 drives the first support rod 22 to rotate. When the two first support rods 22 rotate at the same time, the second support rod 24 is driven by the connecting shaft 23 respectively. Rotate and push the two protective plates 9 to move in the opposite direction of the brake disc. At the same time, the rotating motor 15 runs, so that the worm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com