Covered film for visible light and infrared signature weakening and matching device

A visible light, film-coated technology, used in transportation and packaging, heat exchanger shells, lighting and heating equipment, etc., can solve the problems of inability to guarantee the appearance color, affecting production capacity, danger, etc., to improve survivability and easy operation. , the effect of efficient absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

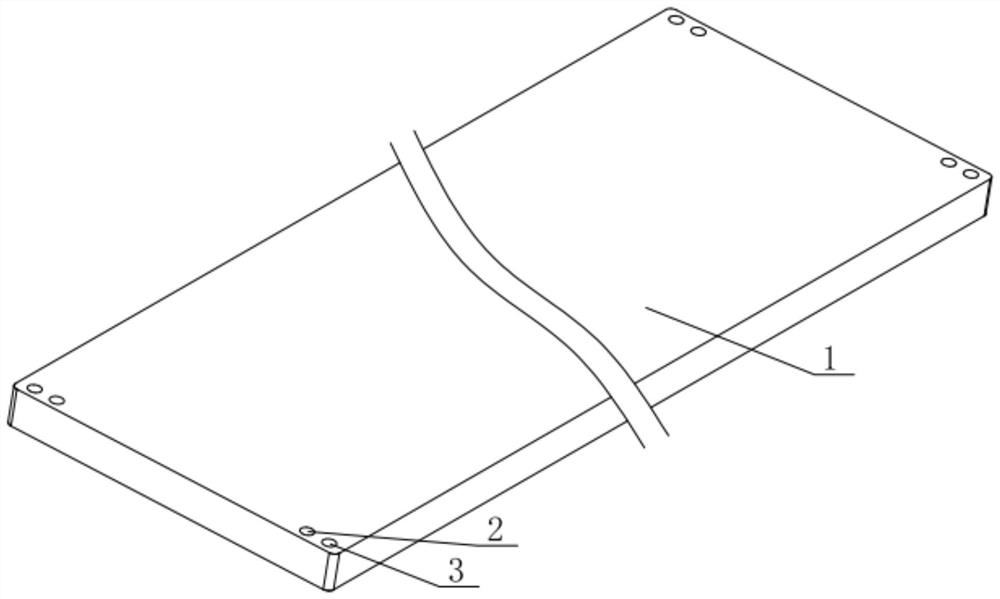

[0039] Such as figure 1 with figure 2 As shown, the coating film for weakening the visible light and infrared characteristics of this embodiment includes a film body 1, the film body 1 is an integrated structure, and a heat exchange interlayer and a color dithering interlayer independent of each other are arranged in the film body 1; The interlayer absorbs heat efficiently, thereby effectively reducing the infrared radiation characteristics of the object to be used, and forms the same color or a dithering effect transformation on the surface of the object to be used through the dithering interlayer, thereby effectively reducing the recognizability of its visible light image;

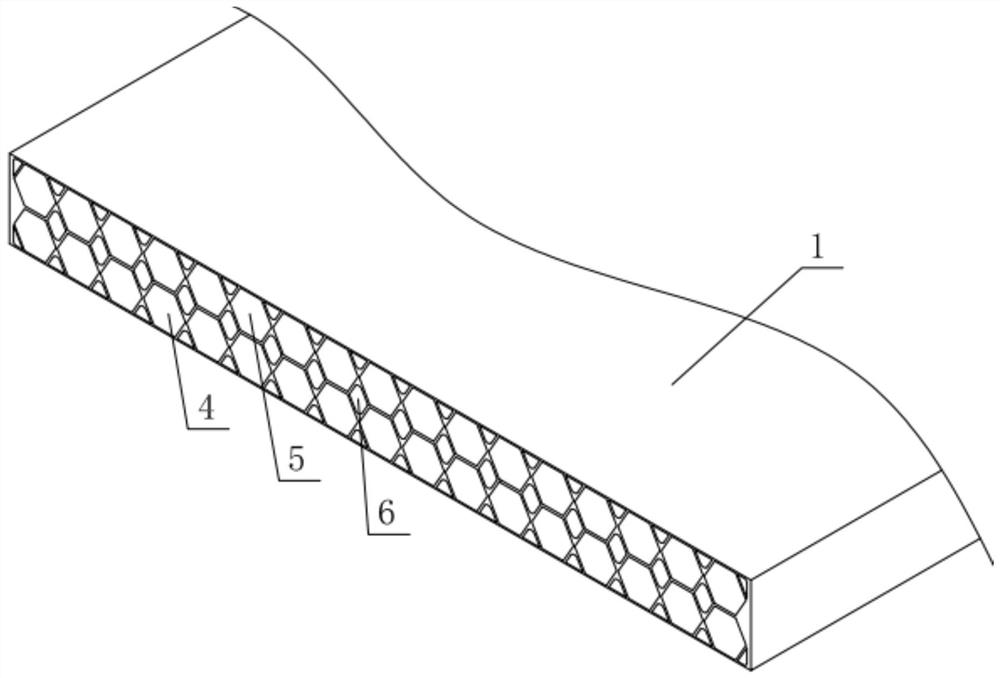

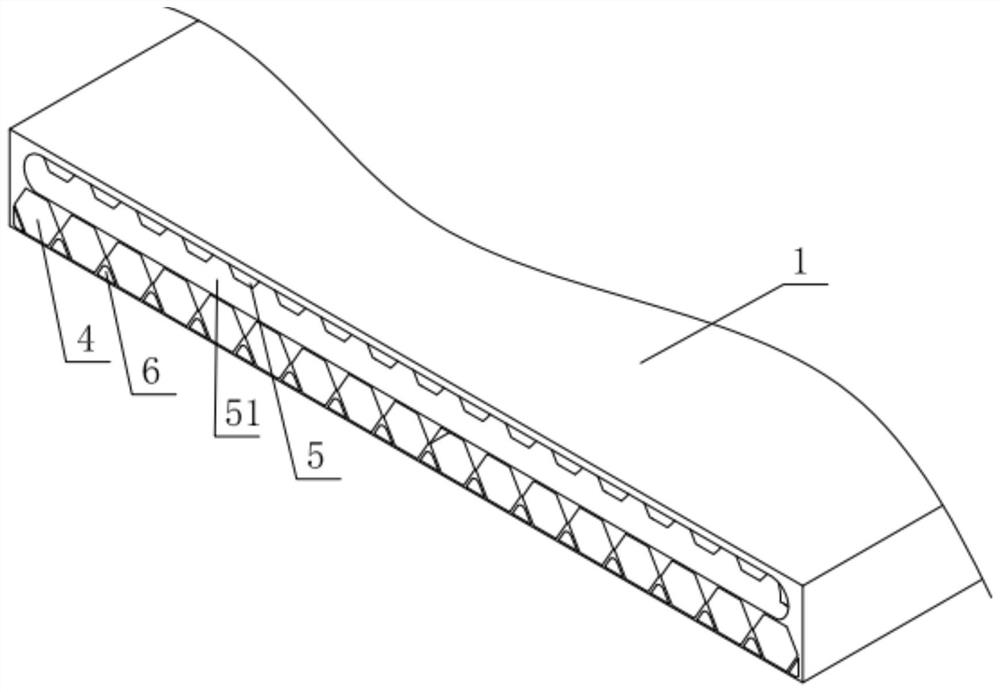

[0040] Such as image 3 with Figure 5 As shown, the structure of the heat exchange interlayer is: including a plurality of heat exchange tubes 5 arranged side b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com