A Bolt Looseness Sensing Device Based on Piezoelectric Traction Effect

A bolt loosening and traction effect technology is applied in the direction of using electric/magnetic devices to transmit sensing components, measuring devices, and testing of mechanical components. It can solve the problems of complex monitoring technology design, low sensitivity and high cost, and avoid loosening. Or damage and fracture, low cost, convenient and quick installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

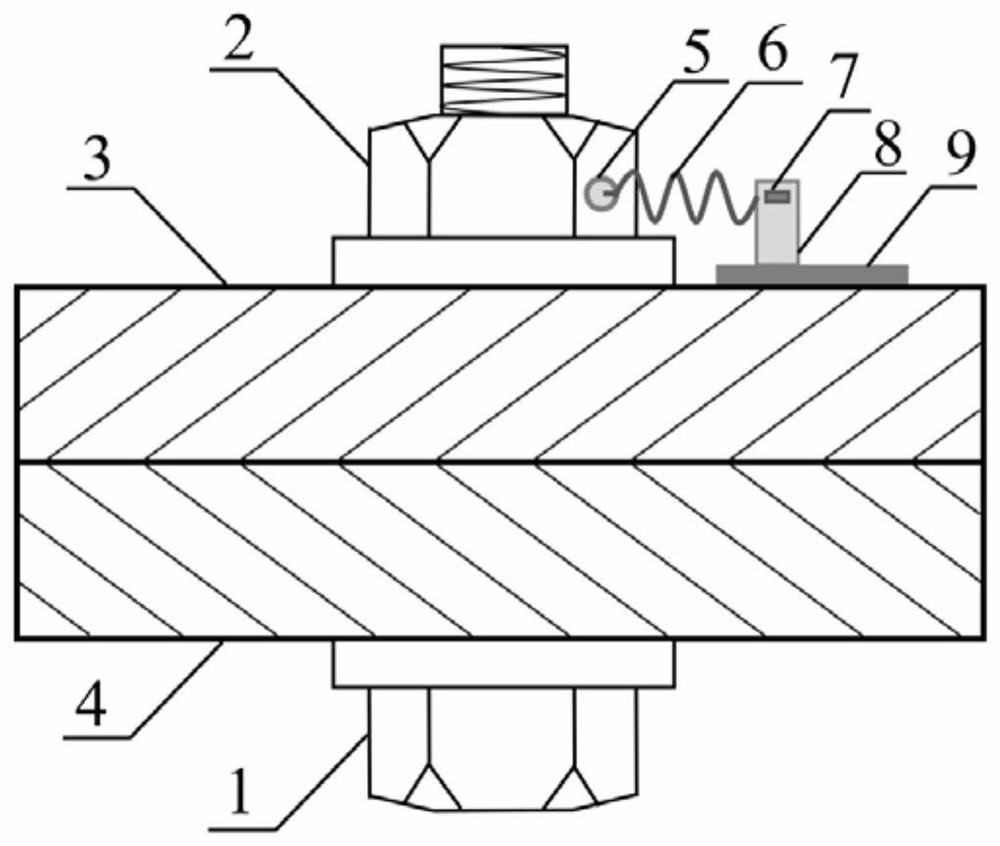

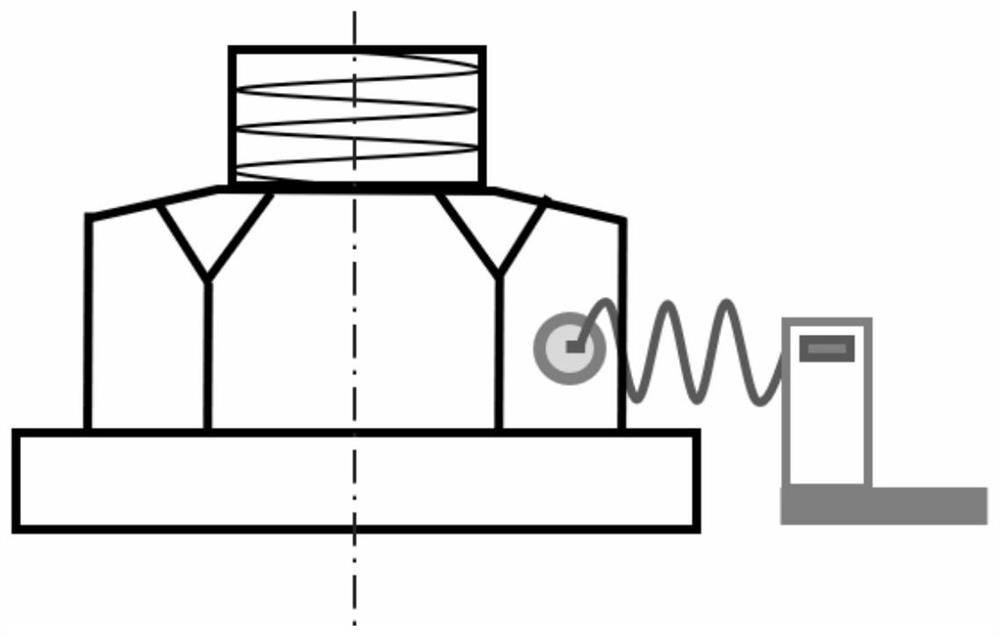

[0022] Specific embodiment one: the following combination Figure 1 to Figure 3 , Figure 5 and Image 6 Illustrating this embodiment, a bolt loosening sensing device with piezoelectric traction effect described in this embodiment includes a connecting end piece 5, a spring 6, a piezoelectric piece 7, a metal elastic piece 8, a bottom bracket 9 and a signal processing module;

[0023] The bottom bracket 9 is embedded with a signal processing module. The upper end surface of the bottom bracket 9 is vertically arranged with a metal dome 8. The piezoelectric plate 7 is attached to the upper end of the metal dome 8. The suspended end of the metal dome 8 is connected to the tail end of the spring 6. The head end is fixedly provided with a connecting end piece 5, and the connecting end piece 5 is pressed on the side of the nut;

[0024] When the bolt is loosened, the connecting end piece 5 swings with the nut, the connecting end piece 5 drives the spring 6 to expand and contract, ...

specific Embodiment approach 2

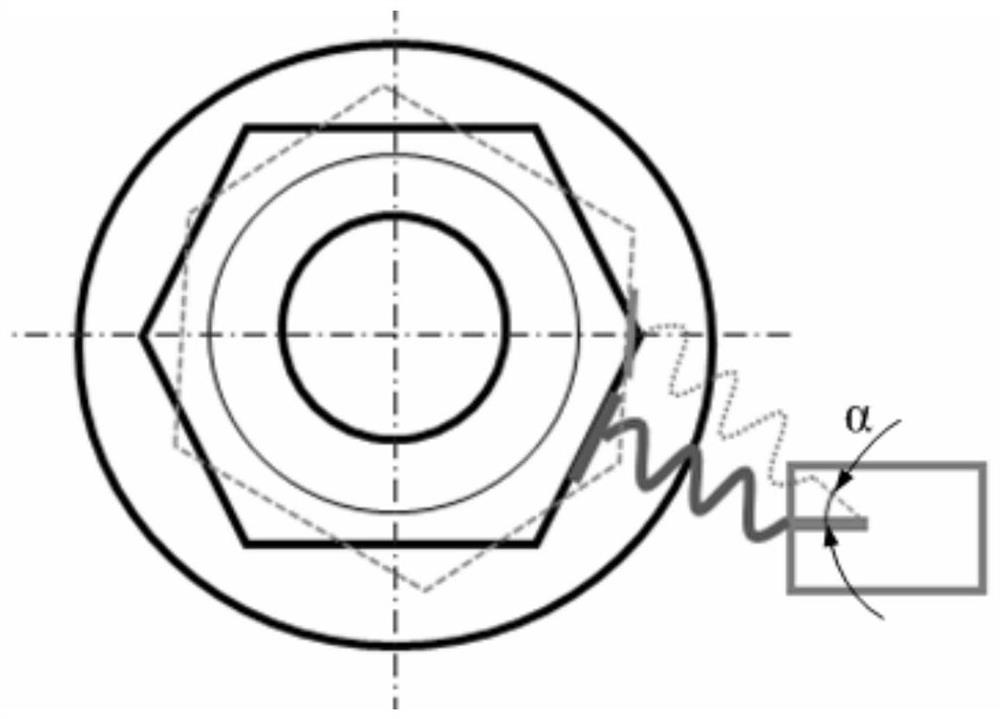

[0030] Specific embodiment two: the following combination Figure 4 Describing this embodiment, the difference between this embodiment and the first embodiment is that the head end of the spring 6 connected to the connecting end piece 5 is an equidistant helical structure, preferably an integrally formed connection. The equidistant helical structure of the spring has an excellent stable structure and a large contact surface, making the connection more reliable.

[0031] The end of the conventional spring is a single circle, and there are often protruding ends at the truncation, which is not conducive to the connection with the connecting end piece 5 and the smoothness of the pressing on the nut.

[0032] In this embodiment, the head end of the spring 6 is changed to an equidistant helical structure in order to increase the contact area with the connecting end piece 5, so that the force transmitted by the spring 6 can be more smoothly and positively supported on the nut 2 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com