Pressure-controllable soft package battery module

A soft pack battery and module technology, applied in battery pack components, secondary batteries, secondary battery testing, etc., can solve the problem of not properly adjusting the battery position, achieve simple and reliable structure, improve service life, and prevent safety effect of accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

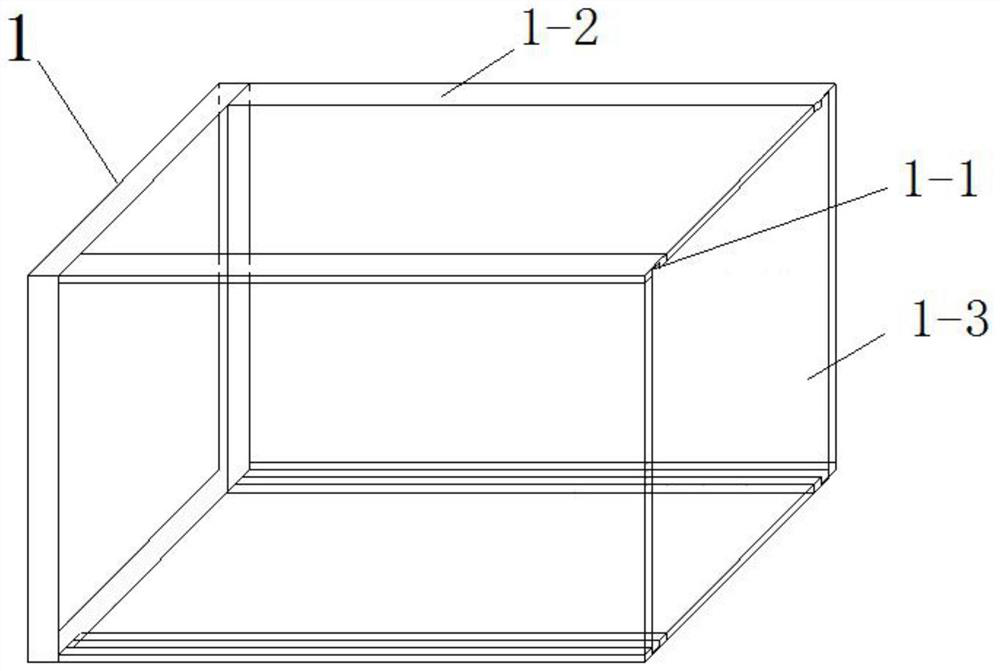

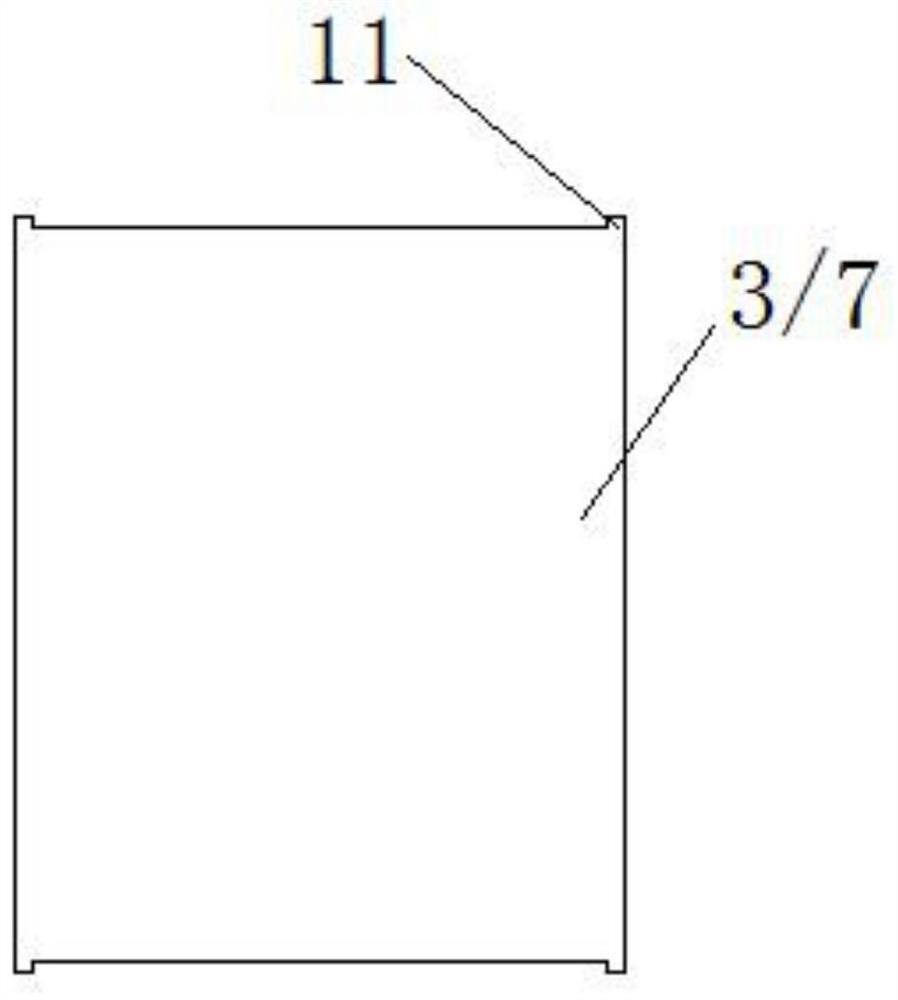

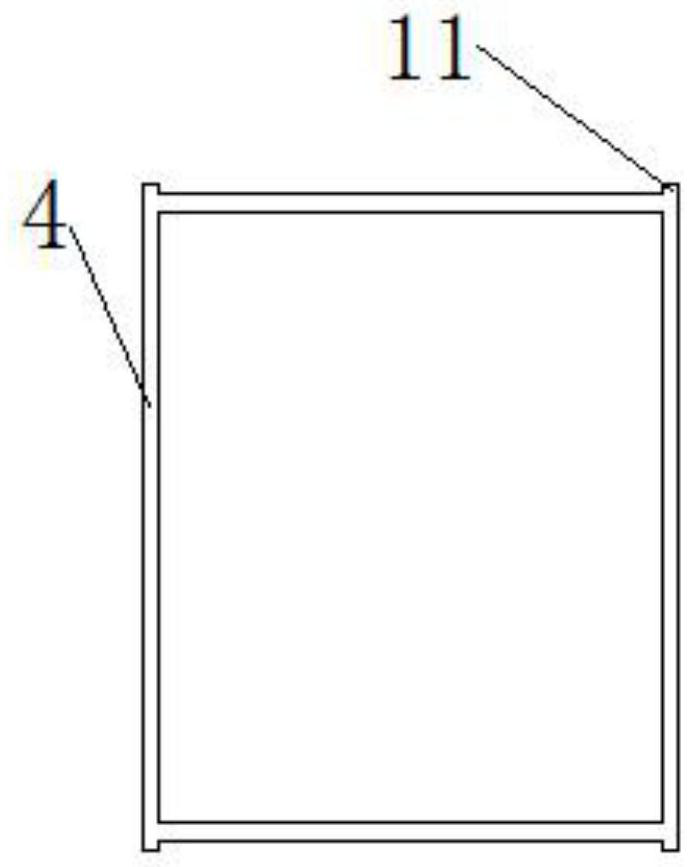

[0030] The following will be combined with Figure 1-4 , to clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, rather than all the embodiments.

[0031] Such as Figure 1-4 As shown, a pressure-controllable pouch battery module has a rectangular module structure frame (1), the structure frame opening (1-3) is set on the right side of the module structure frame (1), and the first separator (3), the single battery fixing frame (4) and the second separator (7) can slide laterally into the module structural frame (1) through the structural frame opening (1-3) in turn, and the single battery (5) can Installed in the single battery fixing frame (4), the pressure sensor (2) is arranged between the first separator (3) and the single battery (5), and the fixing plate (9) can open the structural frame opening (1-3 ) is sealed, one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com