Heat dissipation system of box-type substation

A box-type substation and cooling system technology, applied in the field of substations, can solve problems such as energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is attached figure 1 -X further details the application.

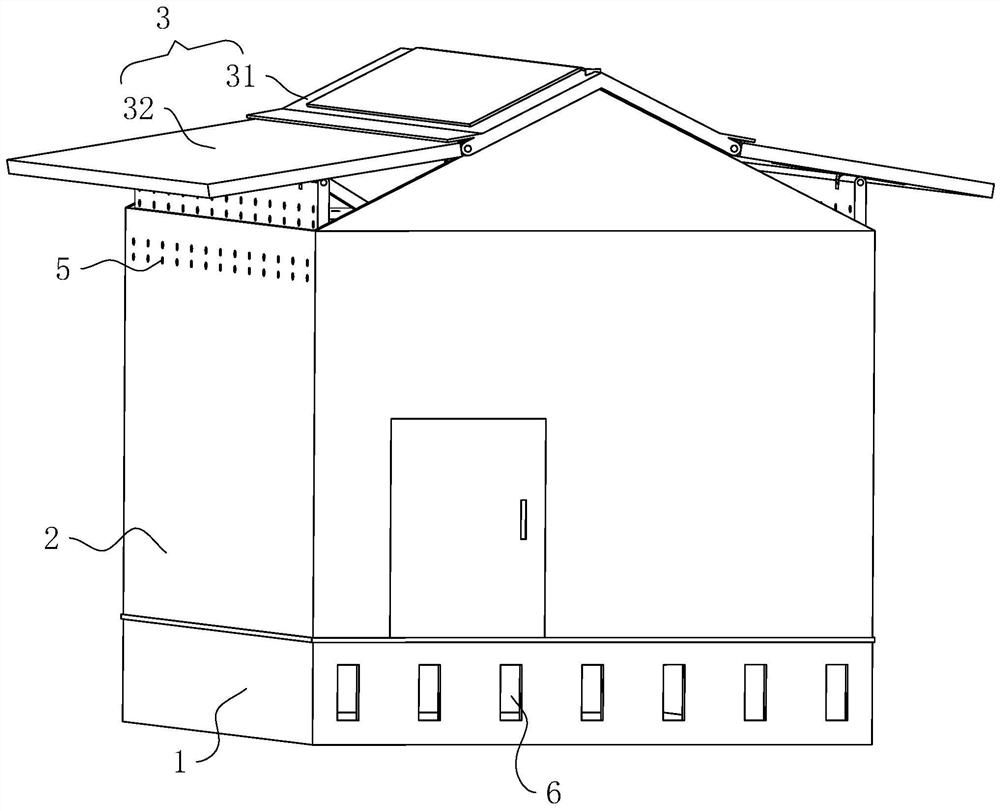

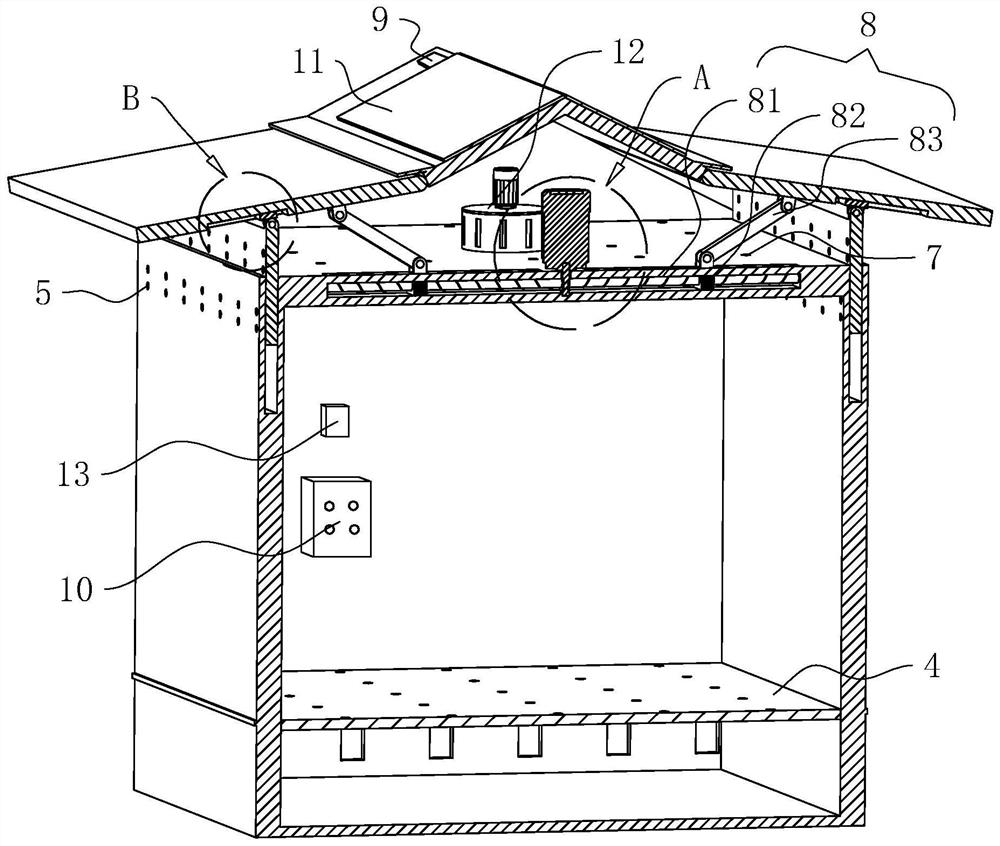

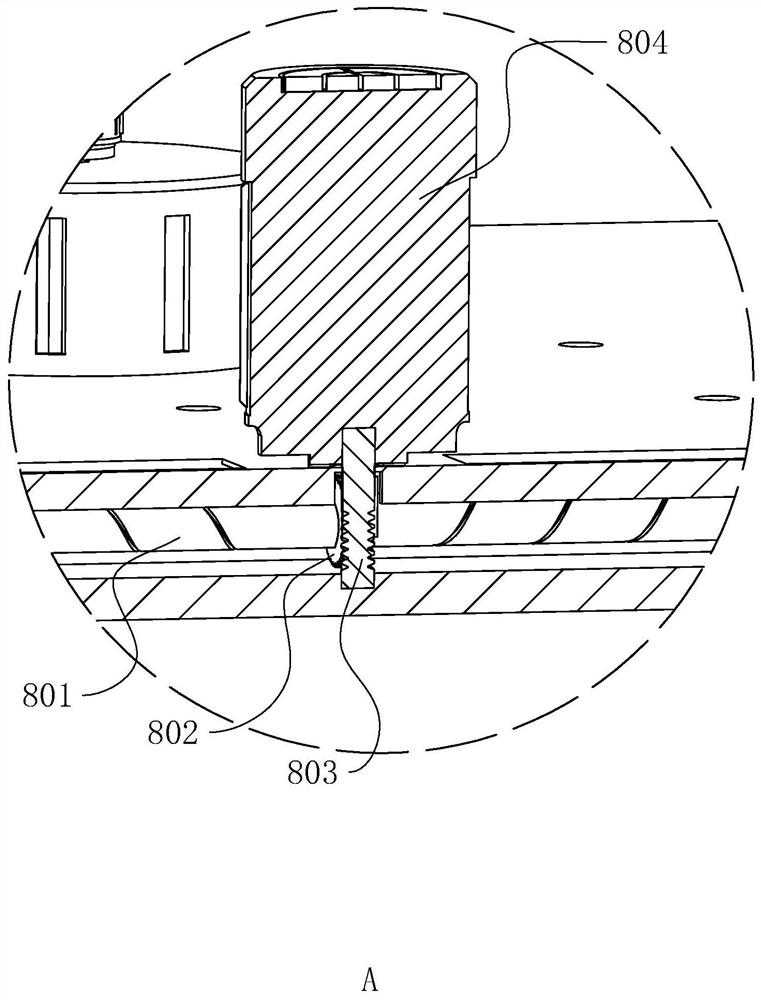

[0032] A box-type substation heat dissipation system, refer to figure 1 and figure 2 , including a base 1, the base 1 is hollow, the base 1 is connected with a box body 2 by bolts, the top of the two opposite side walls of the box body 2 is provided with cooling holes 5, and the top of the box body 2 is provided with a box cover 3, Case lid 3 comprises the top cover 31 that is integrally connected with casing 2 top, and top cover 31 both sides are symmetrically provided with cover plate 32, and cover plate 32 is hinged with top cover 31 bottoms near the side of top cover 31, and cover plate 32 is respectively to The two sides of the heat dissipation hole 5 are arranged obliquely, and the side of the cover plate 32 close to the corresponding heat dissipation hole 5 protrudes from the top of the box body 2. The side wall hinge on one side of the box body 2 is connected with a box door, and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com