Adhesion member and microneedle patch

A technology of adhesive components and adhesives, applied in the direction of microneedles, needles, viscous dressings, etc., can solve the problem of not getting the effect of drug injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] [Example 1] Correlation between rigidity and floating of adhesive tape (patch)

[0128] (1) Calculation method of rigidity

[0129] (1-1) Test method

[0130] According to Japanese Industrial Standard (JIS K7171), passed Figure 13 The rigidity of the test piece (corresponding to the adhesive of the present invention or the support of the patch of the present invention. The same applies hereinafter) was obtained by the three-point bending test shown. The specific test method is as follows.

[0131] The test piece was placed on the two support tables, and the central part was subjected to a force with an indenter to bend it at a constant speed, and the force and deflection applied to the test piece were measured. An example of the load curve of the obtained test results is shown in Figure 14 .

[0132] Device: Small bench-top testing machine EZTest manufactured by Shimadzu Corporation

[0133] Test speed: 1mm / min

[0134] Distance between fulcrums: 12mm

[0135]...

Embodiment 2

[0179] [Example 2] Relationship between rigidity and stress applied to microneedles (evaluation of stress applied to microneedles)

[0180] (1) Production of human skin model

[0181] A silicon sheet (thickness 15 mm) with a hardness of 5 degrees was used as a human skin model. It should be noted that when the elasticity of the present model is compared with the elasticity of the skin, equivalent stress curves are drawn.

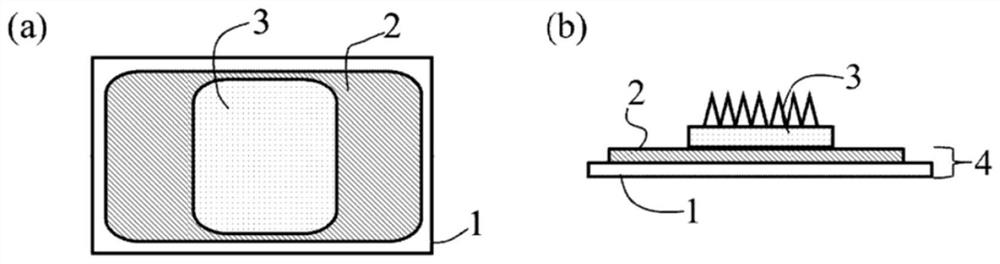

[0182] (2) Measuring method of stress applied to microneedles

[0183] This assay uses as Figure 16 The device shown was carried out. The lifting part of the device is equipped with a load cell, The plunger, the 10mm×10mm×H20mm spacer and the press-in fixture. Press into the fixture as Figure 16 Installed on the lifting part of the device like that, set it on the spacer A through hole through which the plunger connected to the load cell passes.

[0184] A 10 mm x 10 mm x 1 mm thick PET plate serving as a pseudo-microneedle array was placed on a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com