Permeable reaction wall, box structure and realization method of reaction wall

A technology of permeable reaction walls and boxes, which is applied in the direction of basic structure engineering, walls, building components, etc., can solve the problems that restrict the promotion and use of groundwater permeable reaction walls, the situation that complex geological conditions cannot be repaired, and the repair function of groundwater reaction walls is blunt. to achieve the effects of artificially manufacturing and controlling hydraulic gradients, accelerating groundwater flow, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

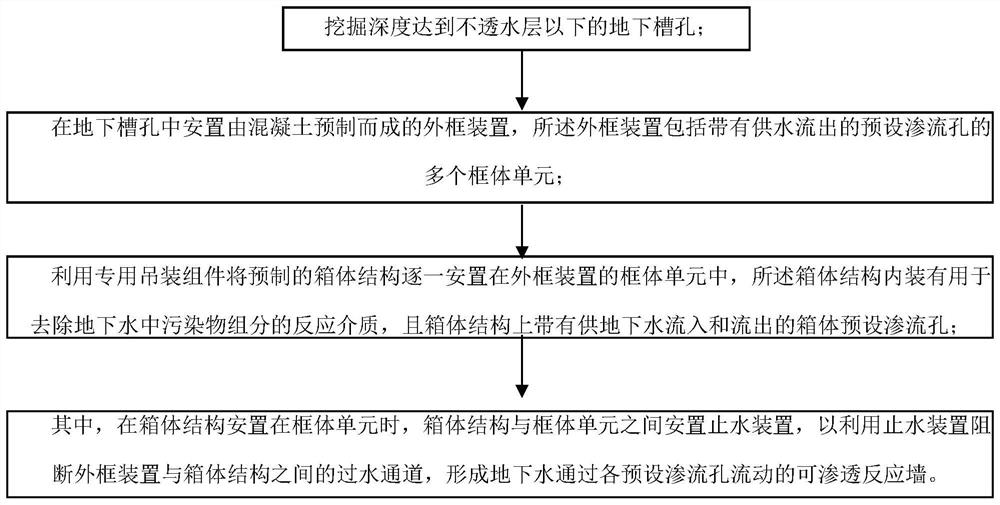

[0076] Such as figure 1 As shown, the flow chart of the method for realizing the permeable reaction wall provided by the present invention, as can be seen from the figure, the method includes:

[0077] Excavation of underground slots whose depth reaches below the impermeable layer;

[0078] placing a prefabricated concrete frame device in the underground tank, the frame device comprising a plurality of frame units with preset seepage holes for water supply to flow out;

[0079] The prefabricated box structure is placed one by one in the frame unit of the outer frame device by using a special hoisting component. The box structure is equipped with a reaction medium for removing pollutant components in groundwater, and the box structure has a and outflow box preset seepage holes;

[0080] Among them, when the box structure is placed in the frame unit, a water stop device is also installed between the box structure and the frame unit, so as to block the water passing between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com