Balling parameter setting method of wire-feeding balling process

A technology of process balls and parameters is applied in the field of spheroidization parameter setting in the feeding spheroidization process, which can solve the problems of waste of wire feeding materials, scrapped castings, poor spheroidization, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

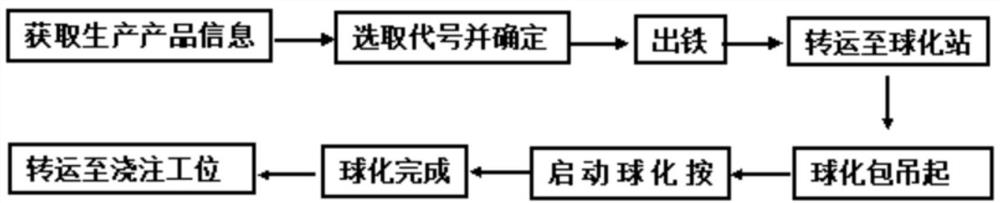

[0019] A method for setting parameters of the spheroidization process of feeding silk spheroidization described in this embodiment includes the following process steps:

[0020] (1) According to the product characteristics, design the tapping amount, tapping temperature and pouring temperature parameters of the product;

[0021] (2) According to the amount of iron in each bag of molten iron and the temperature of the iron, design the number of meters of feeding wire used for each bag of molten iron and the parameters of the wire speed;

[0022] (3) Number the product type and correspond to the number of meters of the wire feeding wire and the wire speed parameters of the product;

[0023] (4) According to the product type, select the product type number, and perform spheroidization according to the number of meters of the wire feeding line corresponding to the number and the wire speed parameters, so as to achieve the effect of stable product quality.

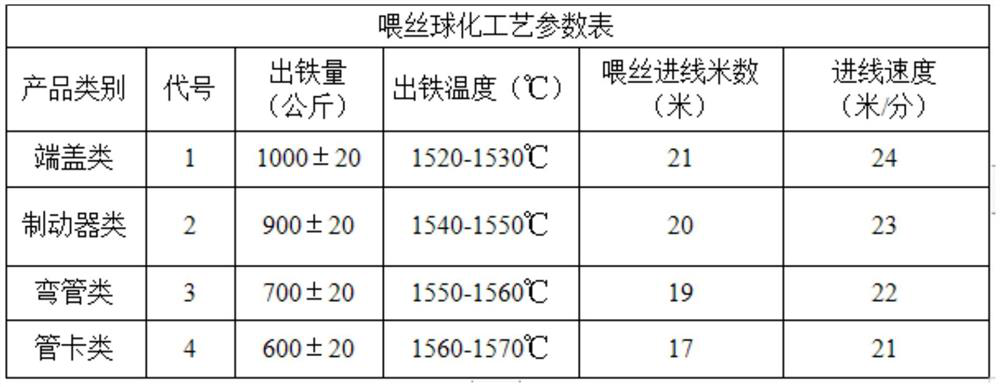

[0024] Specifically, t...

Embodiment 2

[0043] This example takes the end cap product with a tapping temperature of 1520°C as an example:

[0044] (1) Through experiments, according to the amount of iron tapping and the temperature of the iron tapping, the corresponding feeding wire meter and feeding speed are set. After the molten iron is spheroidized, it is detected by a spectrometer to confirm whether the residual magnesium value meets the process requirements: end cover The products were tested for 20 meters, 21 meters and 22 meters respectively through the number of incoming wire meters, and the incoming wire speeds were tested for 23 m / min, 24 m / min, and 25 m / min. The following experimental data were obtained:

[0045] Iron output (kg) 1000 1000 1000 Tapping temperature (℃) 1525 1521 1528 Incoming line meters (meters) 20 21 22 Line speed (m / s) 23 24 25 Residual magnesium content (Baotou) 0.038 0.045 0.055 Residual magnesium content (package tail) 0.032 0.038 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com