Flux-cored wire forming machine and flux-cored wire forming process

A technology of flux-cored welding wire and forming process, applied in welding media, manufacturing tools, welding equipment, etc., can solve the problems of uneven mixing of powder, smaller dispersion coefficient, uneven distribution of graphite powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

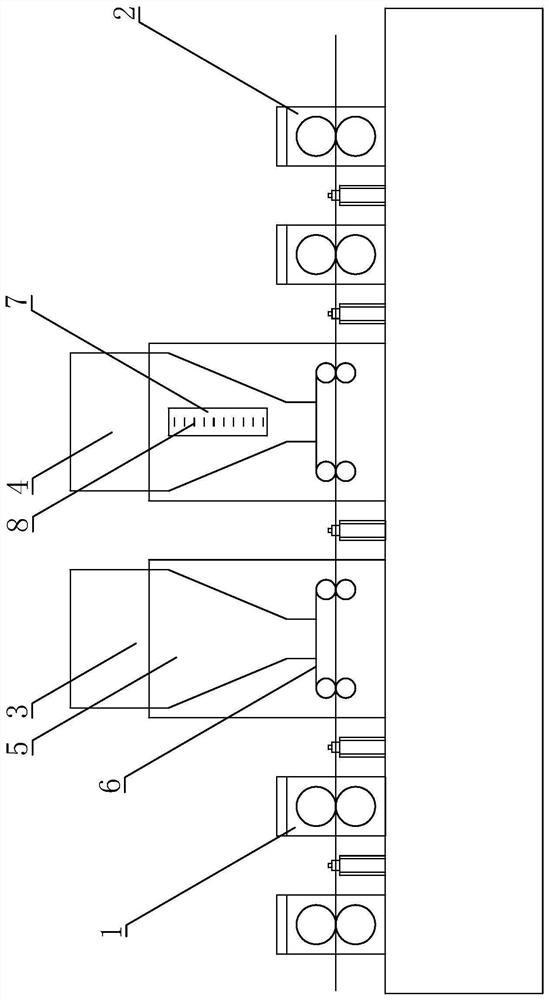

[0026] Embodiment 1: Flux-cored welding wire forming machine, the main structure includes a steel strip rolling U-groove device 1, a seam joint device 2, and also includes a first powder dosing machine 3, a second powder dosing machine 4, and a steel strip rolling U-groove device 1. The steel strip is rolled into a U-shaped steel strip, and the joint joint device 2 is used to joint the U-shaped steel strip filled with powder to form a tubular welding wire. Both the first powder dosing machine 3 and the second powder dosing machine 4 include a powder hopper 5, a powder feeding belt 6, and a servo transmission system. The powder hopper 5 is responsible for storing the powder to be added and sending the powder to the powder feeding belt 6. The powder feeding belt 6 fills the powder into the U-shaped steel belt, and the servo transmission system controls the movement of the powder feeding belt 6 to ensure that the powder feeding belt 6 fills the powder into the U-shaped steel belt ...

Embodiment 2

[0027] Embodiment 2: Flux-cored welding wire forming process, the first step is to change the flat steel strip into a U shape through the steel strip rolling U groove device 1;

[0028] In the second step, the graphite-free powder is added by the first powder feeding machine 3 in the U-shaped steel belt;

[0029] In the third step, graphite powder is added into the U-shaped steel belt by the second dosing powder machine 4. By weight, graphite powder accounts for 3% to 5% of the total content of the medicine powder, and the total filling rate is 42%. The filling rate error is from ± 0.5 %, improved to ±0.1%.

[0030] In the fourth step, the U-shaped steel strip forms a closed tubular welding wire through the joint device 2;

[0031] In the fifth step, the tubular welding wire is rolled into flux-cored welding wires of different diameters.

Embodiment 3

[0032] Embodiment 3: the first step, the flat steel strip becomes U shape through steel strip rolling U groove device 1;

[0033] In the second step, graphite powder is added by the second dosing powder machine 4 in the U-shaped steel belt,

[0034] The 3rd, in the U-shaped steel belt, add the medicine powder not containing graphite by the first medicine powder adding machine 3; By weight, graphite powder accounts for 3%~5% of the total content of medicine powder, and the filling rate of medicine powder is 42%, and the filling rate error is by ±0.5%, improved to ±0.1%.

[0035] In the fourth step, the U-shaped steel strip forms a closed tubular welding wire through the joint device 2;

[0036] In the fifth step, the tubular welding wire is rolled into flux-cored welding wires of different diameters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com