Clamping spring assembling and detecting technology and device

A technology of assembly detection and circlip, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of high error rate, inaccurate detection, inaccurate manual assembly and placement, etc., so as to reduce the cycle time of the station and improve the work efficiency Efficiency and the effect of reducing the workload of manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

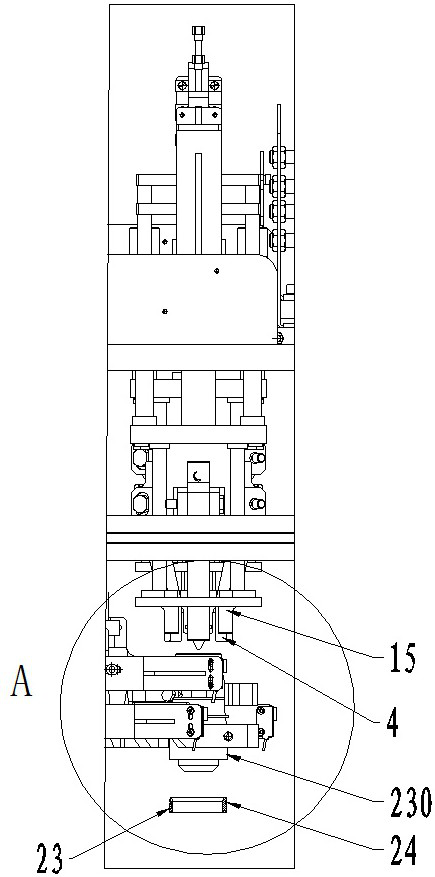

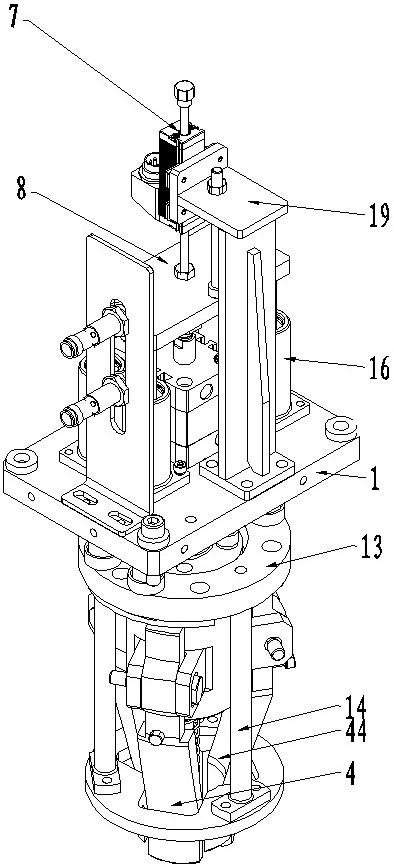

[0034] Example 1, such as Figure 1-5 As shown, a circlip assembly detection process, including

[0035] Prepare materials, manually put the circlips to be assembled into the silo.

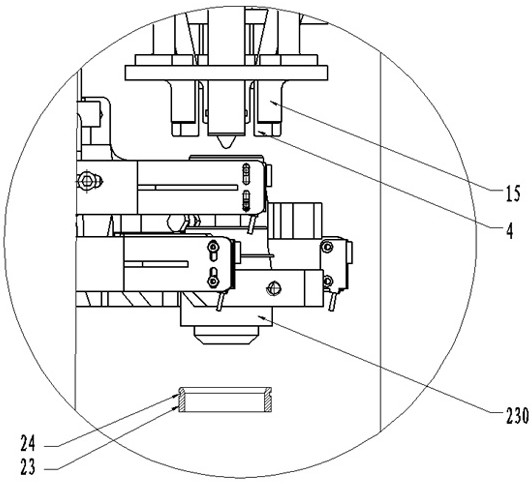

[0036] Blowing, manual jump ring is taken out from feed bin, is placed on the guide block 230.

[0037] The guide block is positioned, the jaws clamp the guide block 230 and move downward until the bottom surface of the guide block 230 moves to the end surface of the snap ring shaft 23,

[0038] The bottom end of the guide block 230 matches the inner diameter of the snap ring shaft 23;

[0039] After the guide block 230 is fixed, the controller sends a command, and the jaws release the guide block 230 .

[0040] The outer diameter of guide block 230 is identical with the outer diameter of jump ring shaft 23;

[0041] Press the circlip, the first cylinder (not shown in the figure) drives the first connecting plate 1 to move vertically downward, the entire press-fit mechanism moves vertically do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com