Terminal positioning screw assembling device

A technology for positioning screws and assembling devices, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., and can solve the problems of low terminal screwing efficiency and terminal screwing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

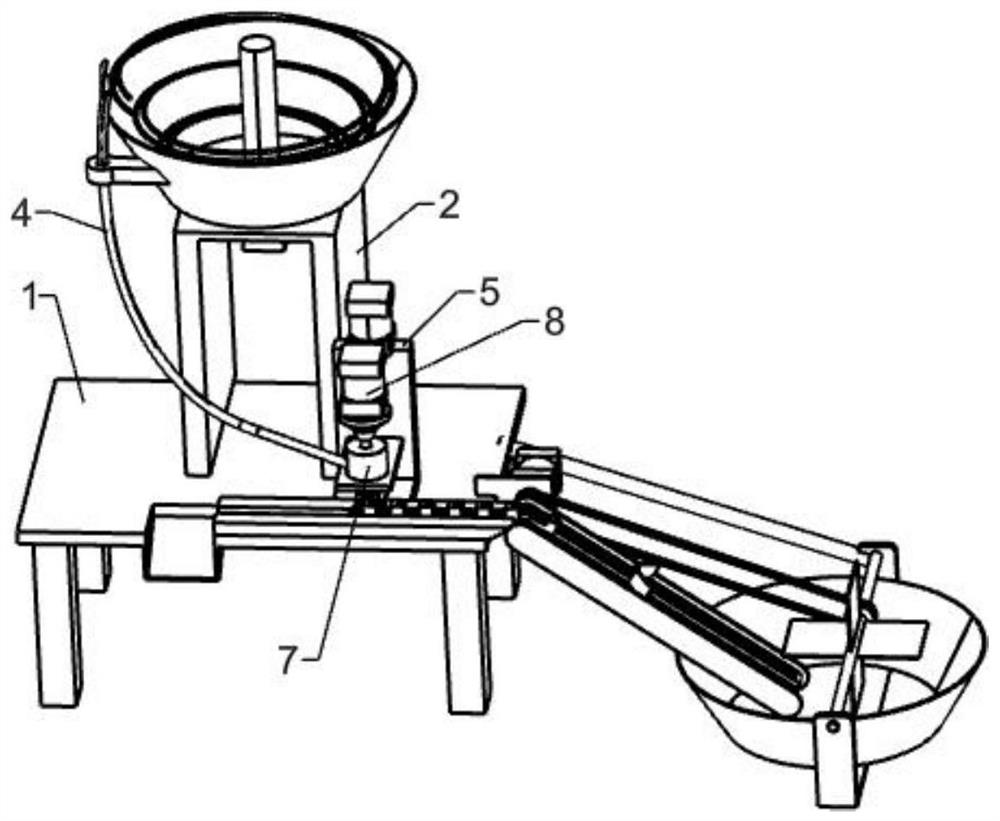

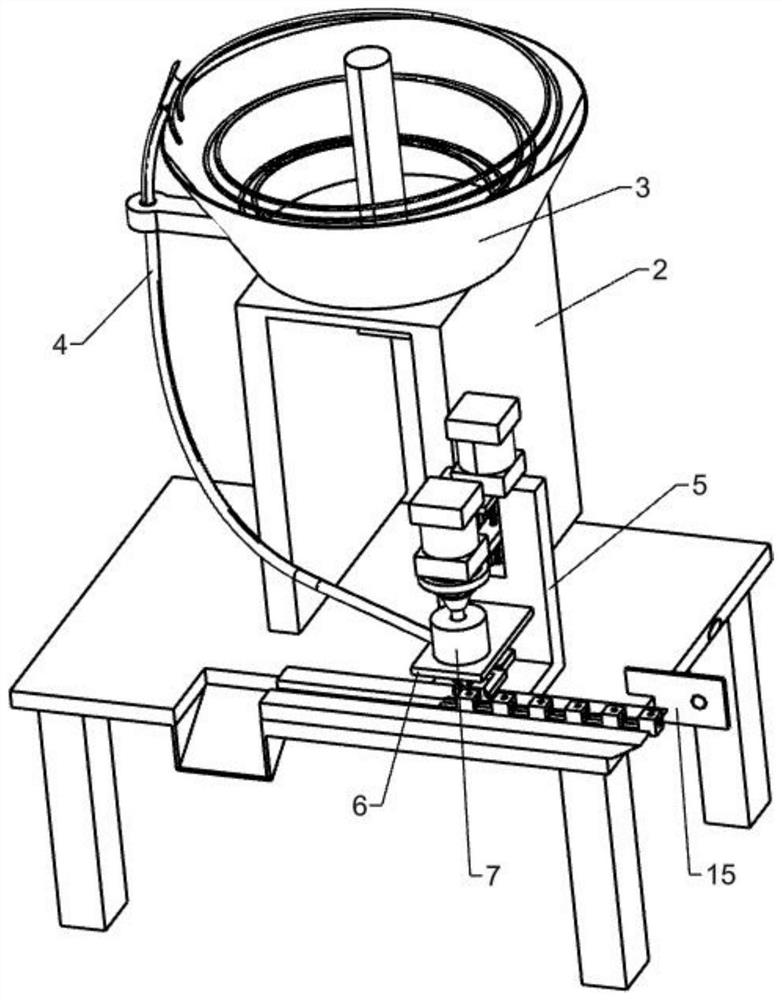

[0029] A terminal set screw assembly device, such as figure 1 and figure 2 As shown, it includes a workbench 1, a connecting frame 2, a vibrating material transfer plate 3, a conveying pipe 4, an L-shaped plate 5, a fixed plate 6, a clamping mechanism 7, a lifting mechanism 8 and a concave conveying frame 14, and the workbench 1 A connecting frame 2 is arranged on the connecting frame 2, a vibrating material transfer plate 3 is installed on the connecting frame 2, a delivery pipe 4 is fixed on the vibrating material transferring plate 3, an L-shaped plate 5 is arranged on the workbench 1 on the front side of the connecting frame 2, and the L-shaped plate 5 A fixed plate 6 is installed on the plate 5, and a clamping mechanism 7 is installed on the fixed plate 6. The clamping mechanism 7 cooperates with the delivery pipe 4. A lifting mechanism 8 is installed on the L-shaped plate 5. The lifting mechanism 8 cooperates with the clamping mechanism 7. , Concave delivery frame 14 i...

Embodiment 2

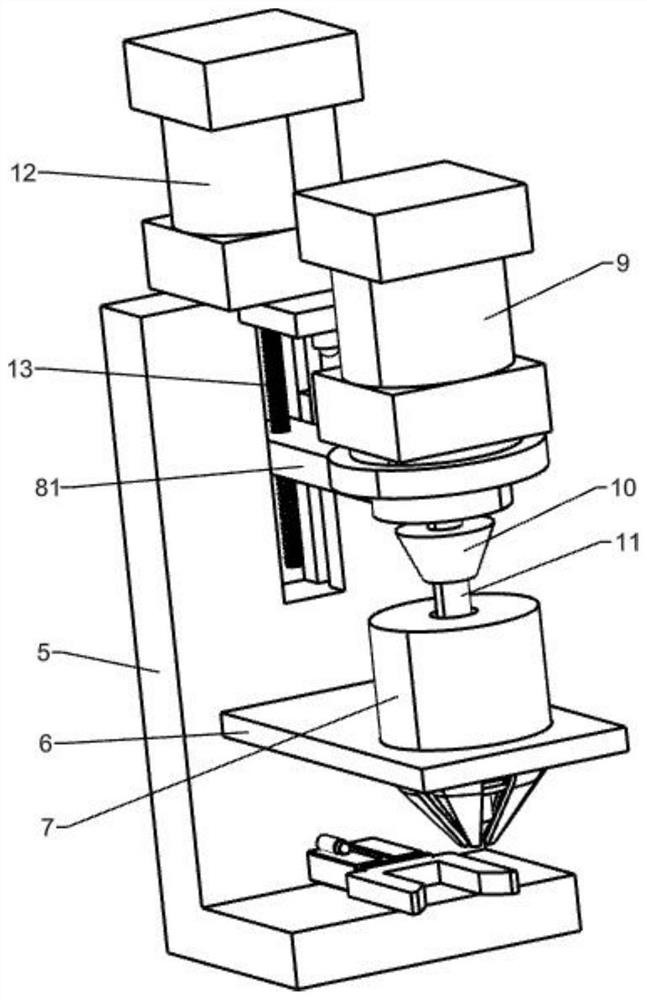

[0032] On the basis of Example 1, such as figure 1 and Figure 5 As shown, the clamping mechanism 7 includes a hollow barrel 71, claws 701 and a first spring 702, the hollow barrel 71 is embedded on the fixed plate 6, the hollow barrel 71 communicates with the conveying pipe 4, and the bottom of the hollow barrel 71 is rotatably connected with There are at least five claws 701 , and a first spring 702 is fixedly connected between the claws 701 and the hollow barrel 71 .

[0033] After the screw enters the conveying pipe 4 by vibrating the material transfer plate 3, the screw in the conveying pipe 4 slides rightward into the hollow barrel 71. Due to the cooperation of the claw 701 and the first spring 702, the screw can be prevented from moving forward. It will fall down and cause inconvenience to screw the terminals.

[0034] Such as figure 1 and image 3 As shown, the lifting mechanism 8 includes a horizontal plate 81, the first motor 9, a mounting block 10, a screwdriver...

Embodiment 3

[0039] On the basis of Example 2, such as figure 1 and Figure 6 Shown, also include the first pulley 17, the second pulley 171, belt 172, connecting plate 20, fixed frame 21, rotating shaft 22, conveying plate 23 and holding dish 24, the servomotor 16 of conveyer 161 rear sides The first pulley 17 is installed on the output shaft, the workbench 1 on the mounting plate 15 rear side is provided with a connecting plate 20, the connecting plate 20 is provided with a fixed mount 21, and the fixed mount 21 is rotatably provided with a rotating shaft 22, the rotating shaft 22 A second pulley 171 is installed on the top, a belt 172 is wound between the second pulley 171 and the first pulley 17, and at least four conveyor plates 23 are fixedly connected to the rotating shaft 22 on the front side of the second pulley 171. 21 is equipped with a holding tray 24, the delivery plate 23 is located in the holding tray 24, and the bottom of the conveyor 161 is located in the holding tray 24....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com