Mixing device facilitating discharging for concrete processing

A mixing device and concrete technology, which is applied in the direction of mixing operation control device, unloading device, clay preparation device, etc., can solve the problems of waste of concrete resources, increase of worker's work intensity, concrete overflow hopper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

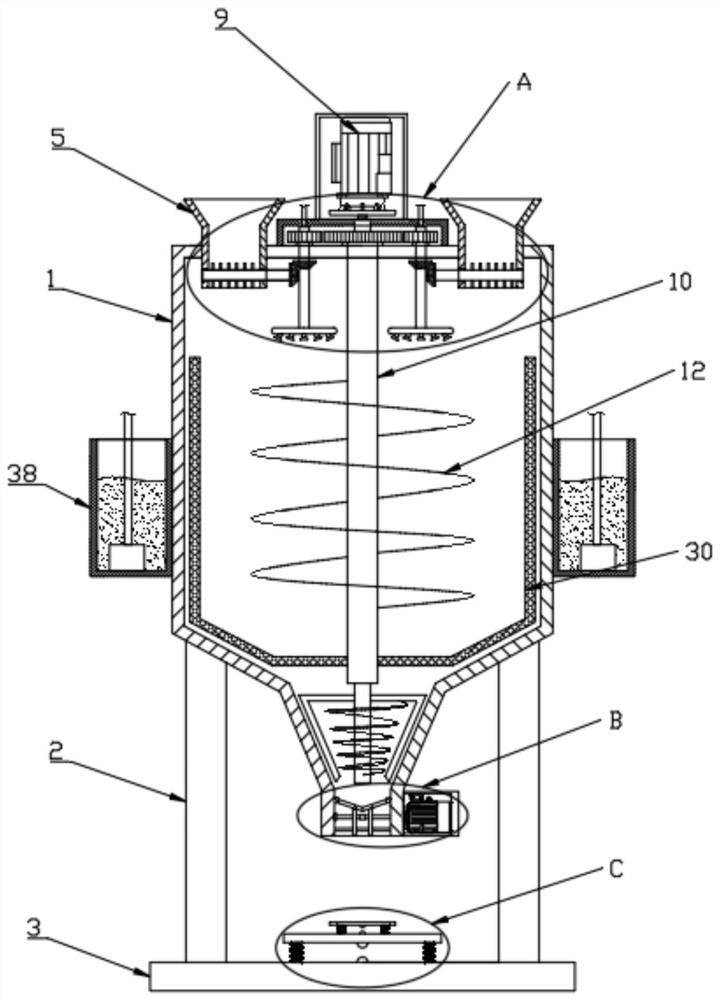

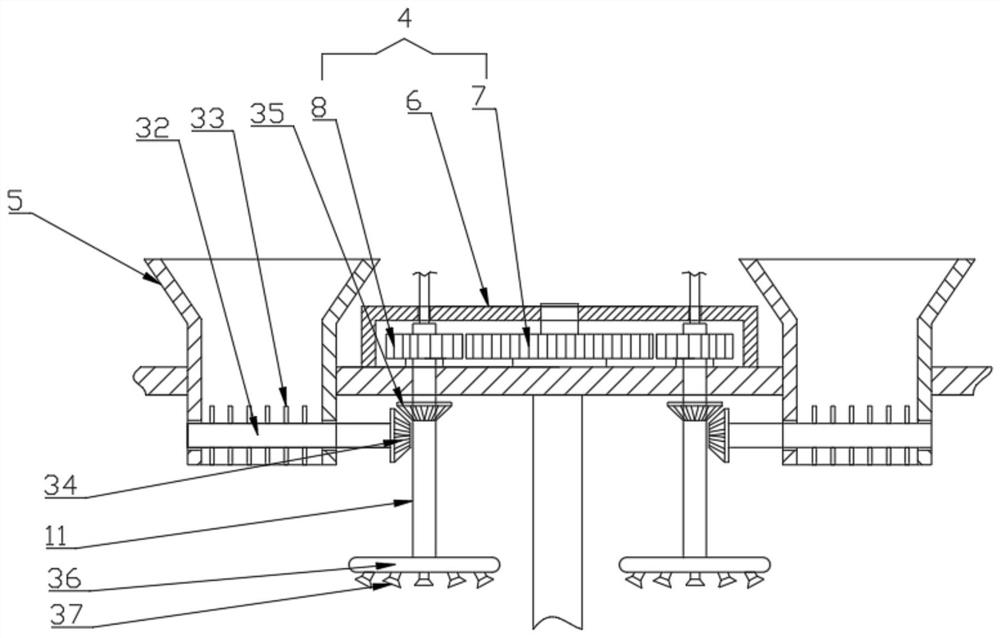

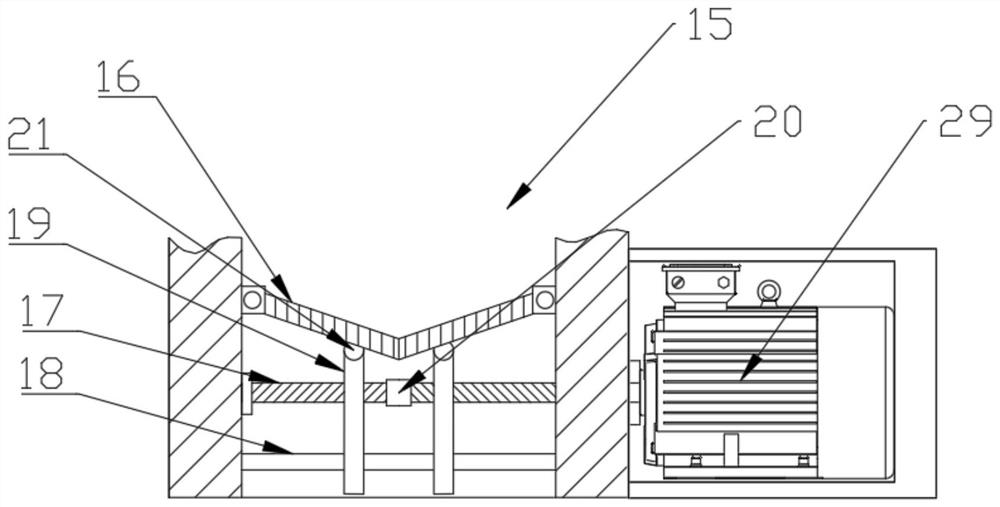

[0025] See Figure 1-5 , Including a mixing tank 1, the bottom of the mixing tank 1 is connected with a base 3 through a support column 2, the top of the mixing tank 1 is provided with a driving mechanism 4, the top of the mixing tank 1 is located on both sides of the driving mechanism 4 symmetrically provided The feed channel 5, and the bottom of the mixing tank 1 is provided with a discharge channel, the drive mechanism 4 includes a drive box 6, a first gear 7 and a second gear 8, the first gear 7 is arranged in the drive box 6 to rotate The first gear 7 is driven by the motor 9 provided on the top of the drive box 6. The second gear 8 is symmetrically arranged on both sides of the first gear 7, and the first gear 7 meshes with the second gear 8. The inside of the first gear 7 and the second gear 8 are respectively sleeved with a stirring rod 10 and a first rotating shaft 11. The stirring rod 10 and the first rotating shaft 11 both penetrate into the stirring tank 1, and the ...

Embodiment 2

[0031] This embodiment has been improved on the basis of embodiment 1, specifically:

[0032] The first rotating shaft 11 is a hollow shaft, and the bottom of the first rotating shaft 11 is provided with a shunt pipe 36. A number of atomizing nozzles 37 are evenly distributed under the shunt pipe 36. The side of the mixing tank 1 is symmetrically arranged The water tank 38 communicates with the top of the first rotating shaft 11 through a water pump and a water pipe. By setting an atomization nozzle 37, the water in the water tank 38 enters the first rotating shaft 11 through the water pump, and passes through the shunt pipe 36 to make the water Spraying from the atomizing nozzle 37, in conjunction with the rotation of the first rotating shaft 11, further expands the spraying area, thereby reducing the generation of dust during concrete mixing, and protecting the surrounding environment.

[0033] The working principle of the present invention is:

[0034] When in use, add concrete r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com