Pretreatment device for plastic infusion tube recycling

A technology for infusion tubes and plastics, which is applied in the field of plastic infusion tube reuse pre-treatment devices, and can solve the problems of plastic infusion tubes being entangled, difficult to stack, and liquid residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Technology for the realization of the present invention

[0026] The means, creative features, purpose and effect are easy to understand, and the present invention will be further elaborated below in conjunction with specific illustrations.

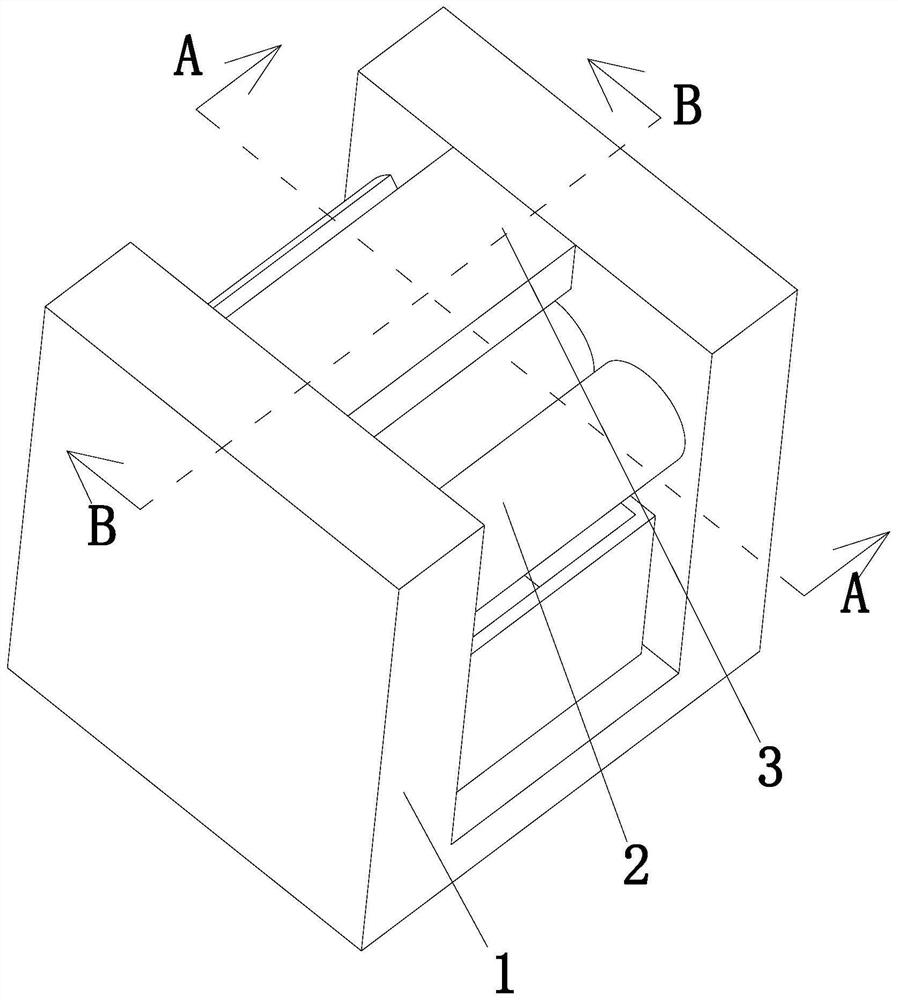

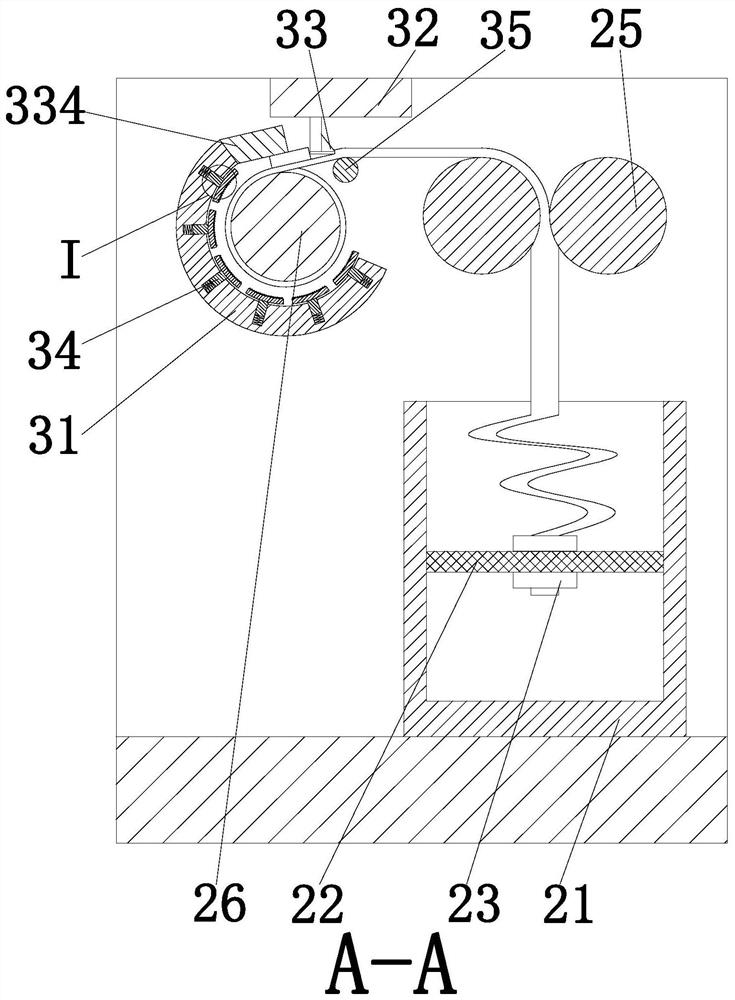

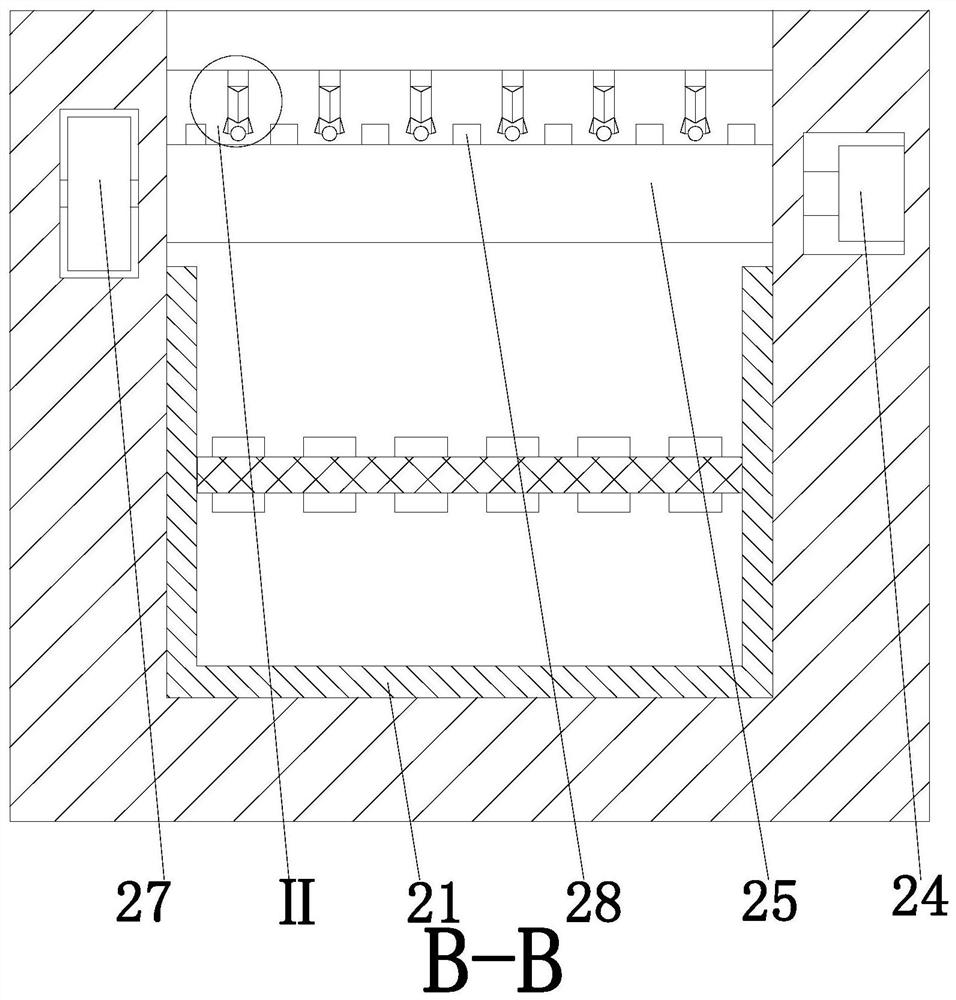

[0027] Such as Figure 1 to Figure 6 As shown, a plastic infusion tube reuse pre-treatment device includes a base frame 1, an extrusion cleaning unit 2 and a cutting and winding unit 3. The inner wall of the lower end of the base frame 1 is provided with an extrusion cleaning unit 2, which is cut and retracted. The rolling unit 3 is arranged between the inner walls of the front and rear ends of the base frame 1; the squeeze cleaning unit 2 squeezes out and collects the liquid remaining in the plastic infusion tube; the cutting and winding unit 3 cuts the plastic infusion tube after preliminary cleaning, and The plastic infusion tube is spread flat and rolled up by extrusion.

[0028] The squeeze cleaning unit 2 includes a waste l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com