Wood-plastic panel drying equipment

A technology for drying equipment and boards, which is applied to flat products, household appliances, and other household appliances, etc., which can solve the problems of poor drying treatment of boards and achieve the effect of avoiding insufficient drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

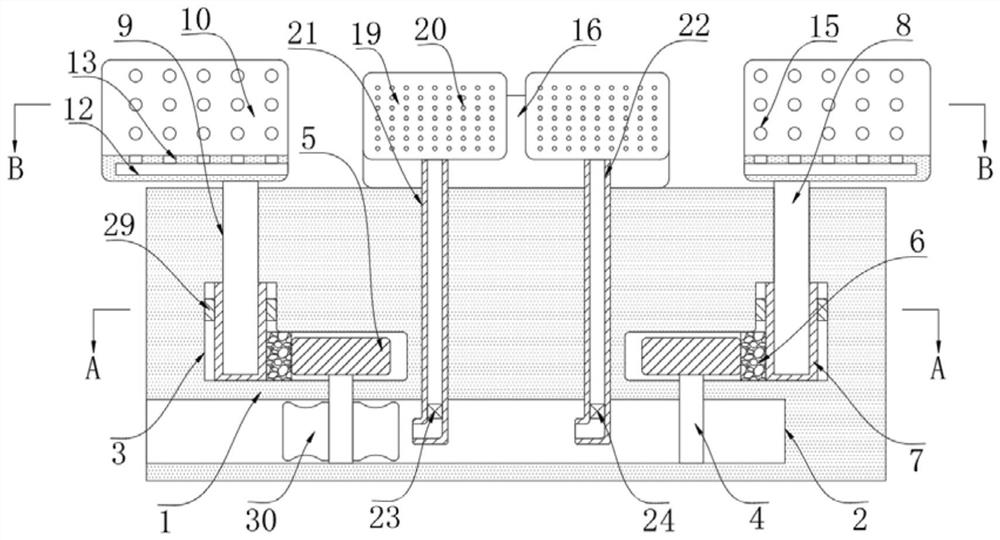

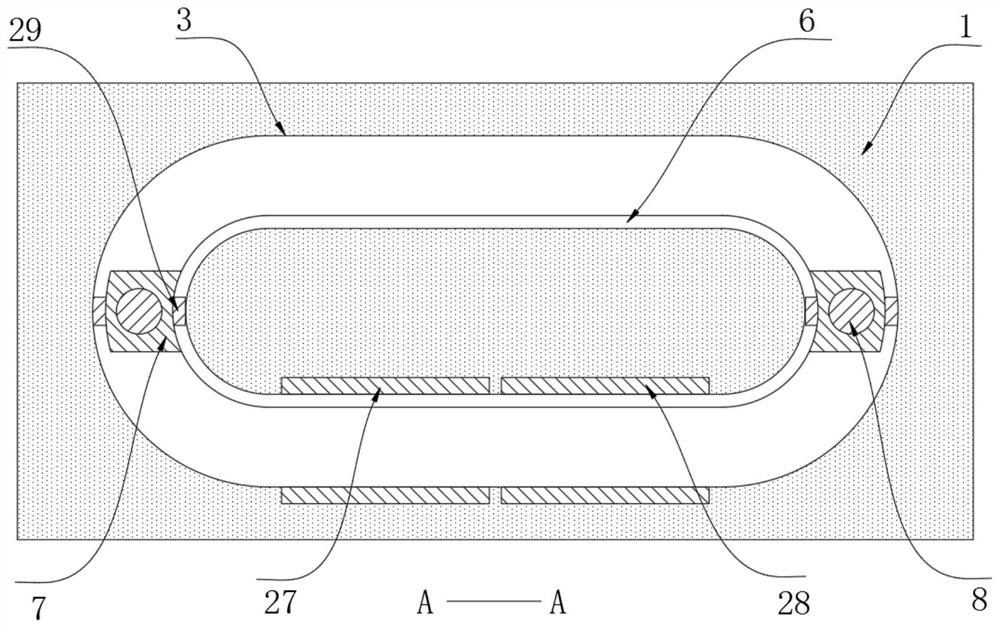

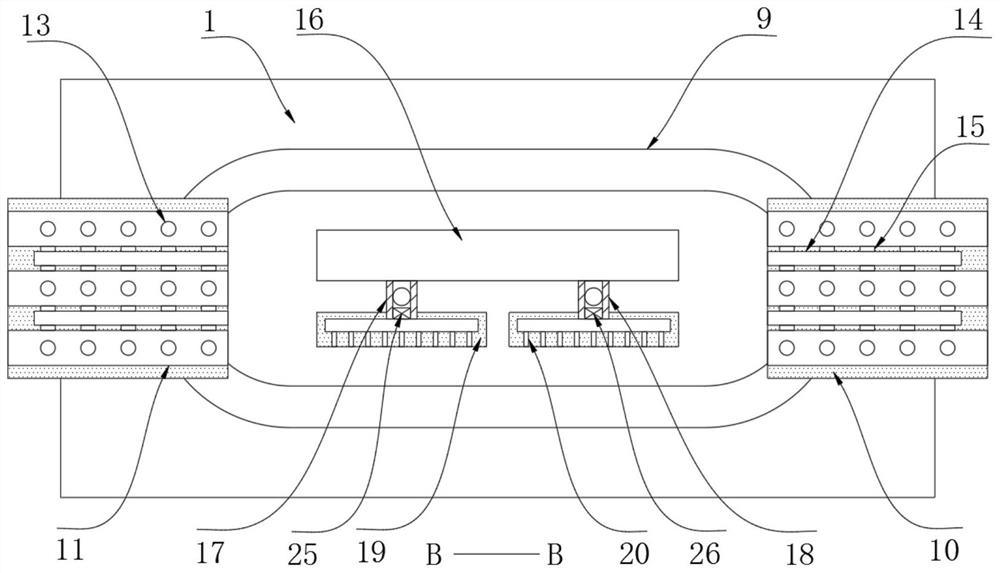

[0020] refer to Figure 1-3 , a wood-plastic board drying equipment, including a base 1, the lower side wall of the base 1 is provided with an air groove 2, the inside of the base 1 is provided with a transmission chamber 3, and the inner bottom of the air groove 2 is rotatably connected with two Rotating shaft 4, the upper ends of the two rotating shafts 4 both extend through the top of the air groove 2 to the inside of the transmission chamber 3 and are fixed with a runner 5, and the two runners 5 are jointly sleeved with a belt 6, and the side walls of the belt 6 are fixed with two Mounting block 7, the inner walls of the two mounting blocks 7 are fixed with pillars 8, the inner top of the transmission chamber 3 is provided with a track groove 9, the upper ends of the two pillars 8 run through the track groove 9 and are fixed with a carrying block 10, the pillar 8 It operates inside the track groove 9, so that the operation of the pillar 8 can be more stable, so that the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com