A Flap Synchronous Drive Control Linkage Mechanism

A technology of synchronous drive and linkage mechanism, applied in the field of unmanned aerial vehicles, can solve the problem of inability to ensure that the flaps move synchronously at the same angle, and achieve the effect of improving energy utilization and overcoming tilt or left-right sway.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

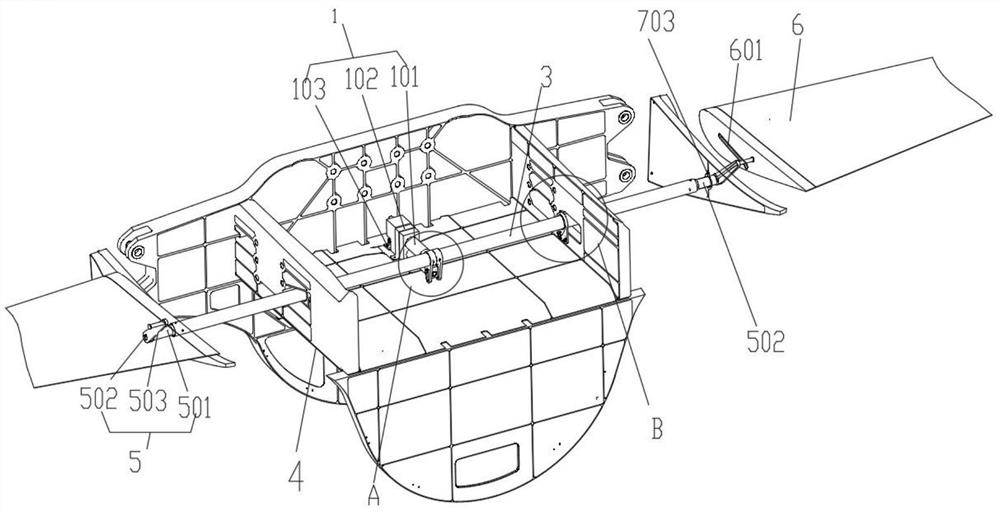

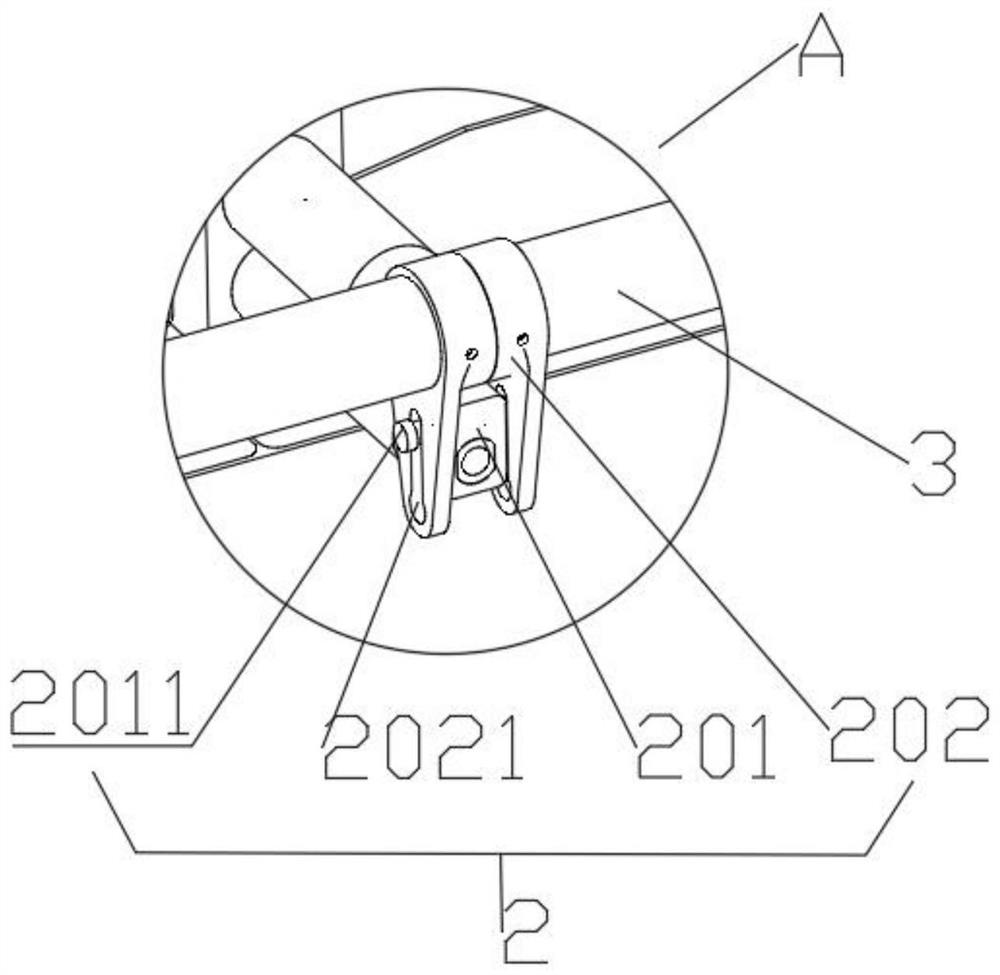

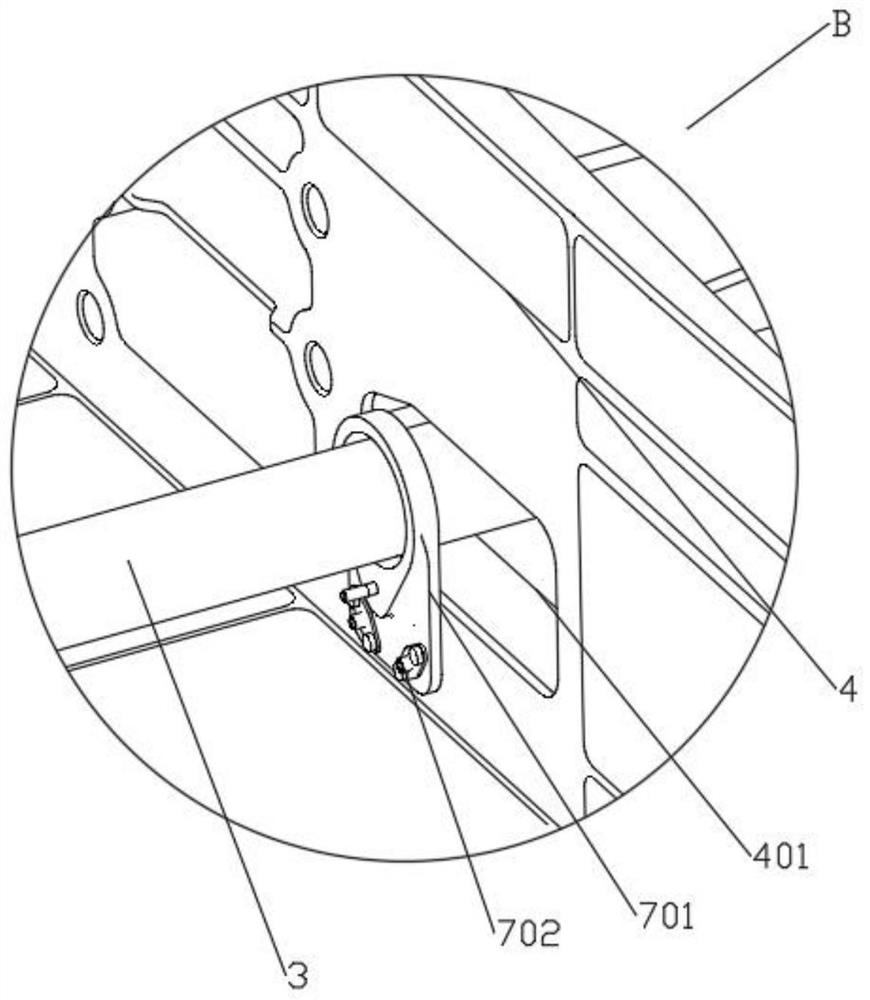

[0044] Such asfigure 1 , figure 2 and Figure 5 , figure 1 It is a three-dimensional schematic diagram of a flap synchronous drive control linkage mechanism provided by an embodiment of the present invention, figure 2 for figure 1 Schematic diagram of the enlarged structure of part A in the middle, Figure 5 A three-dimensional schematic diagram of the connection between the transmission rod and the crank structure in a flap synchronous drive control linkage mechanism provided by an embodiment of the present invention; the flap synchronous drive control linkage mechanism is arranged on the body 4, including:

[0045] A driving mechanism 1, the driving mechanism 1 is fixed to the rear side of the bottom of the body 4 by bolts;

[0046] A connector 2, the output shaft of the drive mechanism 1 is fixedly connected to the connector 2;

[0047] The transmission rod 3, the connecting piece 2 is sleeved at the middle position of the transmission rod 3, the driving mechanism 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com