Construction method of pipe-anchor rock for section steel trestle bridge

A construction method and section steel technology, which is applied in the direction of infrastructure engineering, construction, sheet pile walls, etc., can solve the problems of low difficulty, long cycle time, and large engineering volume, and achieve the effect of small cost investment, short cycle time, and short construction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

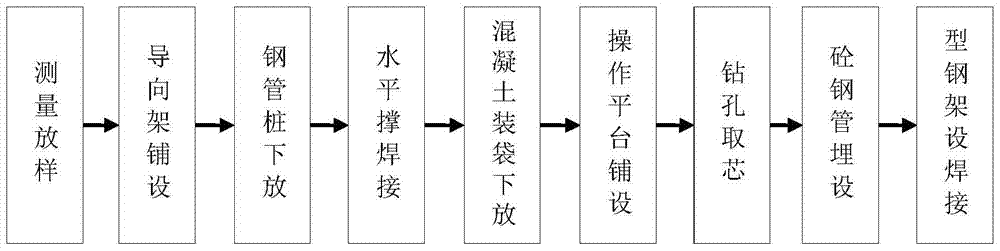

[0041] Such as figure 1 As shown, the construction method of the anchored rock for the built-in pipe of the steel trestle of the present invention includes measurement and lofting, guide frame laying, steel pipe pile laying, horizontal bracing welding, concrete bagging and laying, operating platform laying, drilling core, concrete steel pipe There are several steps for burying, steel erection and welding.

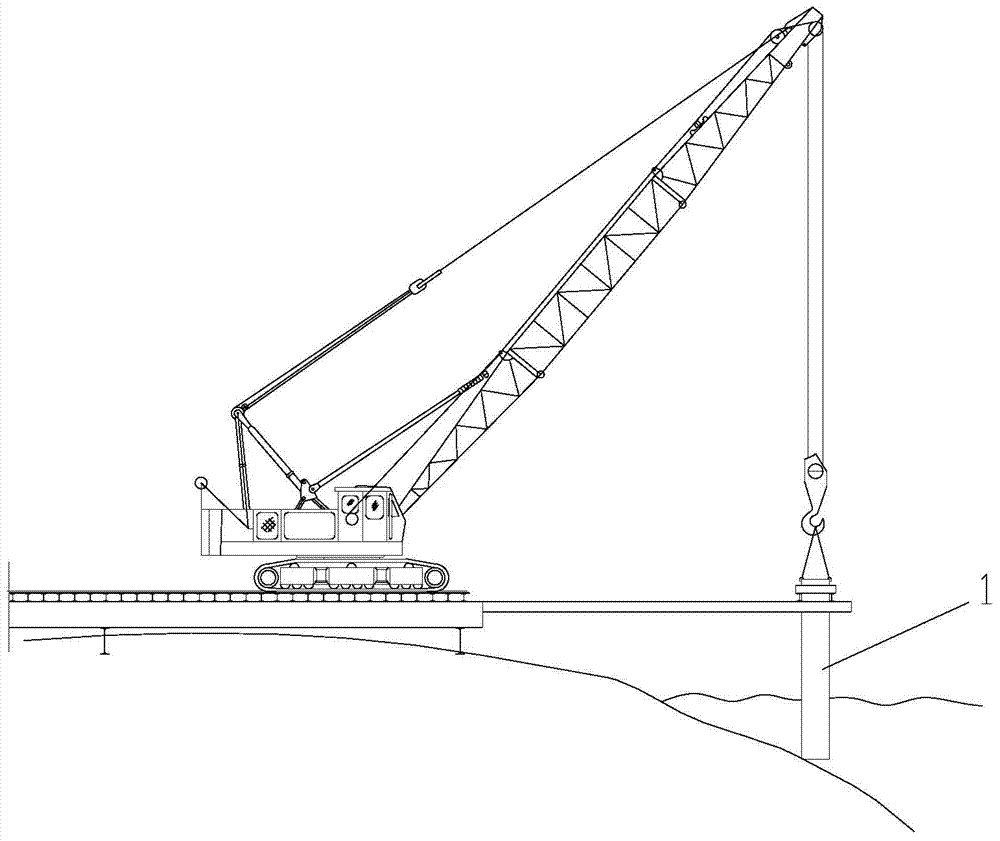

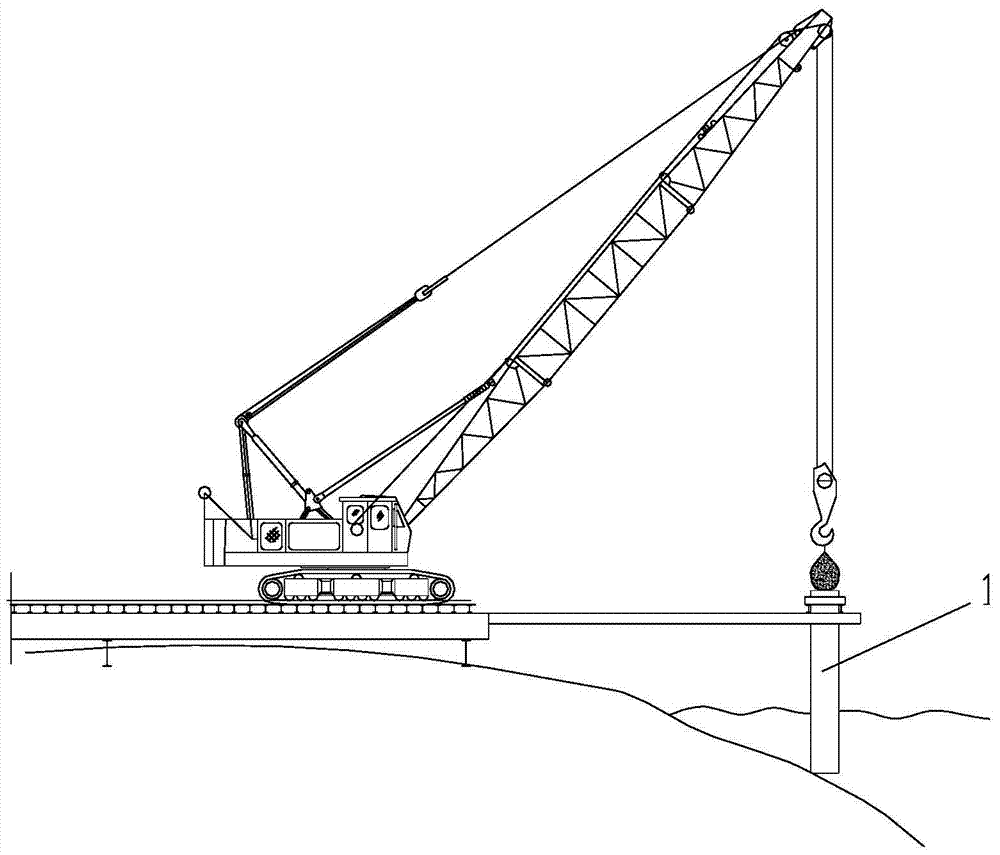

[0042] Figure 2-Figure 9 Is a schematic diagram of the specific steps, combined with Figure 2-Figure 9 The steps are as follows:

[0043] (1) Measuring and setting out

[0044] Before the trestle is erected, the overall plan and cross-sectional layout of the trestle should be drawn in the CAD software, combined with the actual topography of the site, drawn according to the actual coordinate position, and the erection plan should be selected. First...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com