Weaving method of wide tubular fabric

A tubular fabric and wide-width technology, applied in fabrics, textiles, papermaking, textiles, etc., can solve the problems that the comfort of three-dimensional pattern fabrics cannot meet the needs, the density of fabrics is inconsistent, and the pattern lodging is inconsistent, etc., to enhance market competition Advantages, the effect of solving yarn breakage and shortening the production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

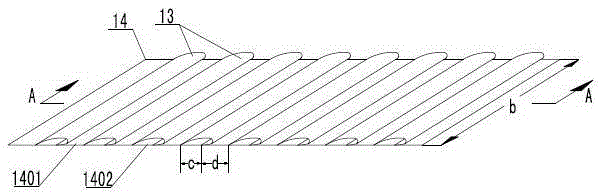

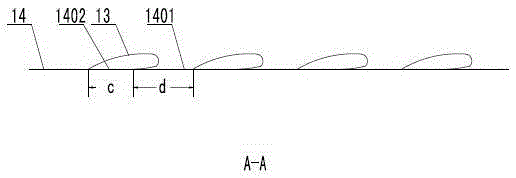

[0038] Embodiments 1 to 5 are specific embodiments of the weaving method of a tubular fabric of the present invention, wherein embodiment 1 is the best embodiment.

[0039] Example 1

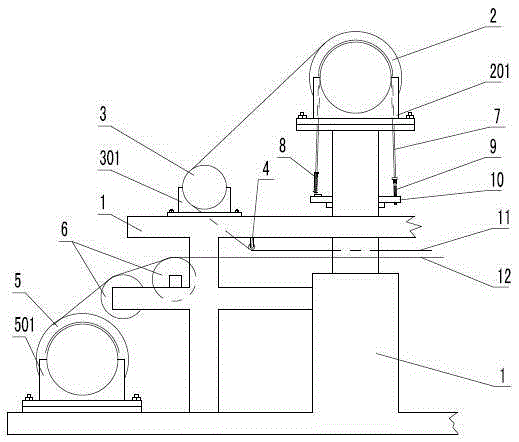

[0040] The steps include warping, sizing, and weaving; the equipment used in the sizing and weaving steps is the double warp beam air-jet loom of the present invention;

[0041] Warping: warp and weft yarns are warped in batches by warping machines; the threading machine adopts the method of threading the yarn through the mother shaft first, and after the cloth surface is opened, the mother shaft is layered and twisted in advance After cutting the shafts, the upper weaving shaft and the lower double weaving shafts are respectively warped; the warp and weft yarns in the yarn are pure cotton; the total number of warp yarns is 12,400, including 80 side yarns on both sides in the width direction, The number of side yarns on both sides is equal; the warp side warping speed is 500~510m / min, and the...

Embodiment 2

[0045] The steps include warping, sizing, and weaving; the equipment used in the sizing and weaving steps is the double warp beam air-jet loom of the present invention;

[0046] Warping: warp and weft yarns are warped in batches by warping machines; the threading machine adopts the method of threading the yarn through the mother shaft first, and after the cloth surface is opened, the mother shaft is layered and twisted in advance , after the shafts are cut, the upper weaving shaft and the lower double weaving shafts are respectively warped; the warp and weft yarns in the yarn are pure cotton; the total number of warp yarns is 12,500, including 80 side yarns on both sides in the width direction, The number of side yarns on both sides is equal; the warp side warping speed is 510~520m / min, and the warp beam winding hardness is 70~72;

[0047] Sizing: immerse the warp and weft yarns in the size for sizing; the size for sizing is polyvinyl alcohol 1~8g / L, starch 1~10g / L, acrylic ac...

Embodiment 3

[0050] The steps include warping, sizing, and weaving; the equipment used in the sizing and weaving steps is the double warp beam air-jet loom of the present invention;

[0051] Warping: warp and weft yarns are warped in batches by warping machines; the threading machine adopts the method of threading the yarn through the mother shaft first, and after the cloth surface is opened, the mother shaft is layered and twisted in advance After cutting the shafts, the upper weaving shaft and the lower double weaving shafts are respectively warped; the warp and weft yarns in the yarn are pure cotton; the total number of warp yarns is 12600, including 90 side yarns on both sides in the width direction, The number of side yarns on both sides is equal; the warp side warping speed is 530~540m / min, and the warp beam winding hardness is 73~75;

[0052] Sizing: dip warp and weft yarns into sizing agent for sizing; the sizing agent for sizing is mixed with polyvinyl alcohol 7g / L, starch 3g / L, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com