A Grading Optimization Method for Sand and Gravel Aggregate

A technology of grading optimization and aggregates, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc. It can solve the problems of single, unreasonable, and incapable evaluation methods, and simplify the sand and gravel adjustment steps. , reduce the amount of glue material, improve the effect of easy performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for optimizing the gradation of sand and gravel aggregates, comprising the steps of:

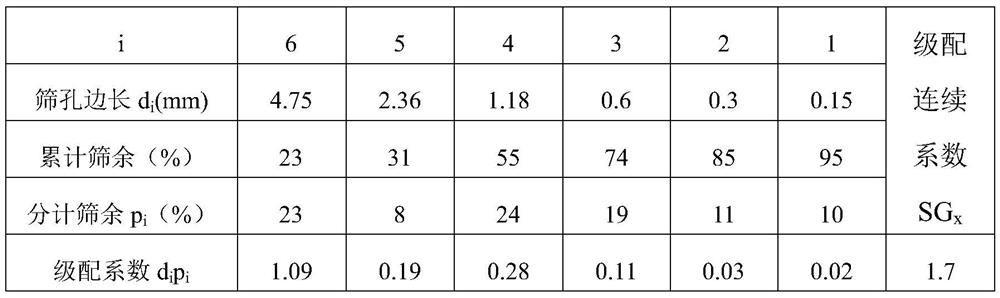

[0023] 1) For aggregates of 0-5mm (nominal particle size), the aggregates to be optimized are screened with 4.75mm, 2.36mm, 1.18mm, 0.6mm, 0.3mm, and 0.15mm standard sieves to obtain different particle size intervals The graded aggregate (6 grades) of the graded aggregate of grade i, where the ratio of sub-metered and sieved aggregate of grade i is p i , the corresponding sieve side length is d i , and i is numbered sequentially according to the increasing particle size; the specific screening results are shown in Table 1;

[0024] 2) According to the sieving results described in Table 1, according to the formula SG m =∑d i p i Calculate the initial gradation continuity coefficient SG of sand and gravel aggregate 0 =(4.75×23%+2.36×8%+1.18×24%+0.6×19%+0.3×11%+0.15×10%)=1.7;

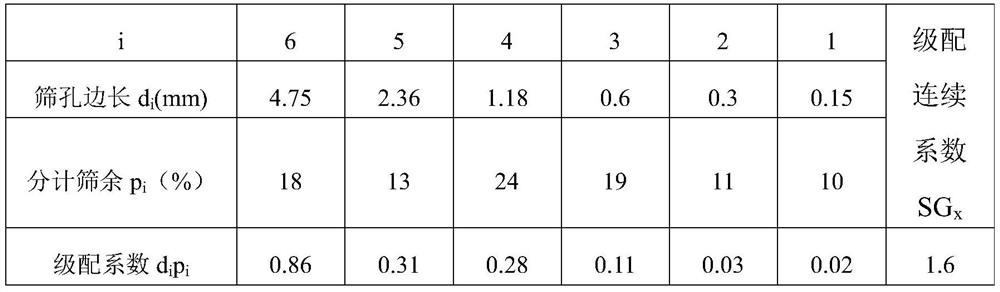

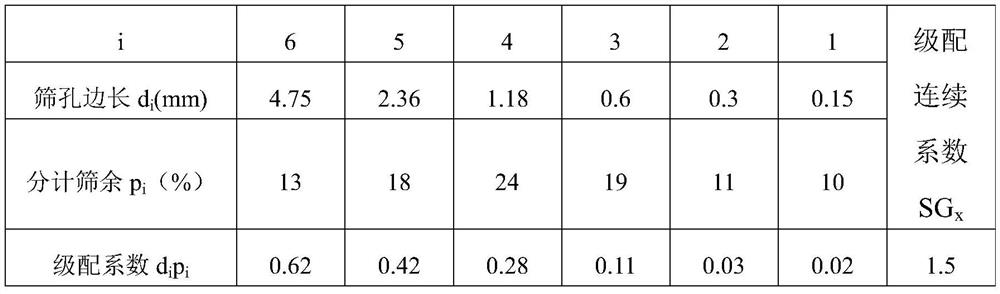

[0025] 3) Calculated initial gradation continuity coefficient SG 0 Greater than aggregate targe...

Embodiment 2

[0041] A method for optimizing the gradation of sand and gravel aggregates, comprising the steps of:

[0042] 1) For aggregates of 5-20mm (nominal particle size), the aggregates to be optimized are screened with 19mm, 16mm, 9.5mm, and 4.75mm standard sieves to obtain graded aggregates in different particle size ranges (4 grades) , where the proportion of sub-calculated and sieved aggregate of grade i is p i , the corresponding sieve side length is d i , and i is numbered in order of increasing particle size; the specific screening results are shown in Table 5;

[0043] 2) according to the screening result described in table 5, according to the formula SG x =∑d i p i Calculation of Gradation Continuity Coefficient SG of Sand and Gravel Aggregate x ; Calculated initial gradation continuity coefficient SG 0 =(19.0×13%+16.0×15%+9.5×37%+4.75×30%)=9.8; within the standard range (9.0-10.5) of sandstone aggregate gradation continuity coefficient sand in Table 1, the gradation op...

Embodiment 3

[0048] A method for optimizing the gradation of sand and gravel aggregates, comprising the steps of:

[0049] 1) For coarse aggregates of 5-25mm (nominal particle size), the aggregates to be optimized are sieved with 26.5mm, 19.0mm, 16.0mm, 9.5mm, 4.75mm standard sieves to obtain the classification of different particle size intervals Aggregate (grade 5), where the ratio of sub-calculation and sieve residue of grade i graded aggregate is p i , the corresponding sieve side length is d i , and i is numbered in order of increasing particle size; the specific screening results are shown in Table 6;

[0050] 2) according to the screening result described in table 6, according to the formula SG m =∑d i p i Calculate the initial gradation continuity coefficient SG of sand and gravel aggregate 0 =(26.5×1%+19.0×17%+16.0×15%+9.5×37%+4.75×22%)=10.5;

[0051] 3) Calculated preliminary gradation continuity coefficient SG 0 Smaller than aggregate target grading continuity coefficient...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com