Base oil and lubricating oil

A base oil and alkyl technology, applied in the field of base oil and lubricating oil containing the base oil, can solve the problems of low Noack volatilization loss, unable to meet low viscosity and low pour point at the same time, and achieve low volatilization loss and low viscosity. , the effect of low pour point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

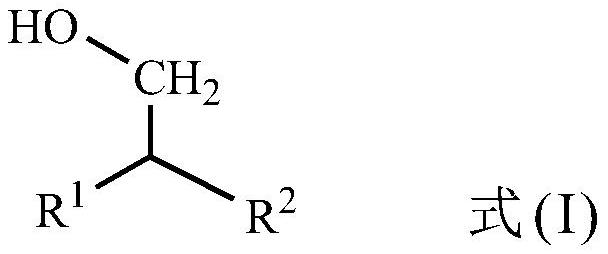

Method used

Image

Examples

Embodiment 1

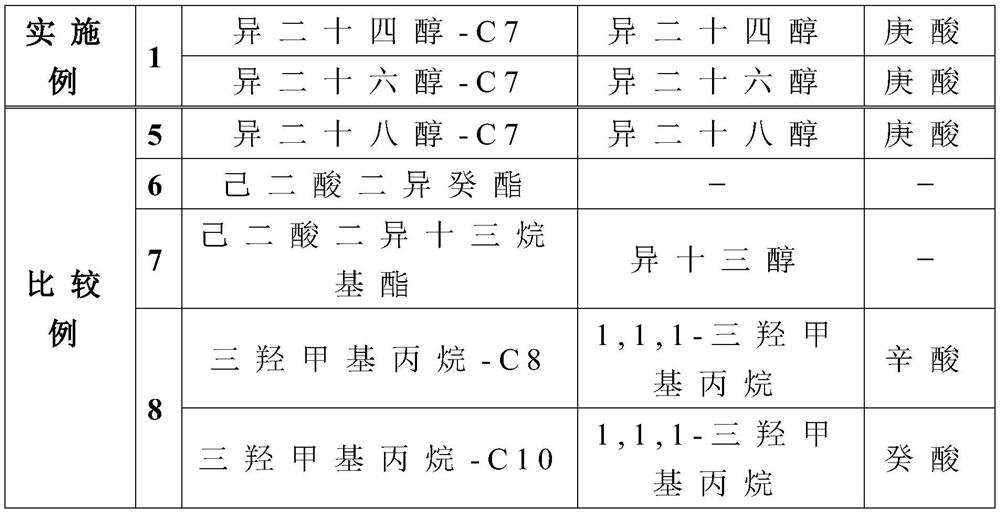

[0041] The preparation methods of the base oils of Example 1 and Comparative Examples 1 to 8 are as follows.

[0042] base oil

[0043] Mix the monoester obtained from isotetracohol and heptanoic acid (abbreviated as isotetradecyl alcohol-C7) and the monoester prepared from isoformyl alcohol and heptanoic acid (abbreviated as Cetyl alcohol-C7), obtain the base oil of embodiment 1. Based on the total weight of the base oil as 100wt%, the weight range of the monoester (isotetracosanol-C7) prepared from isotetracosyl alcohol and heptanoic acid is 40 wt%. The weight range of the monoester (isobehenyl alcohol-C7) prepared by alcohol and heptanoic acid is 60wt%.

[0044] base oil

[0045] The base oils of Comparative Examples 1, 6-7 are made of monoester [isotridecyl stearate (isotridecyl stearate)] or diester [diisodecyl adipate (diisodecyl adipate)] listed in Table 1 respectively. Or diisotridecyl adipate (diisotridecyl adipate)].

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com