Chemical fiber textile machine

A textile machine and chemical fiber technology, applied in textiles, textiles, papermaking, knitting, etc., can solve problems such as staff injury, expansion of textile machine fires, and production line fires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

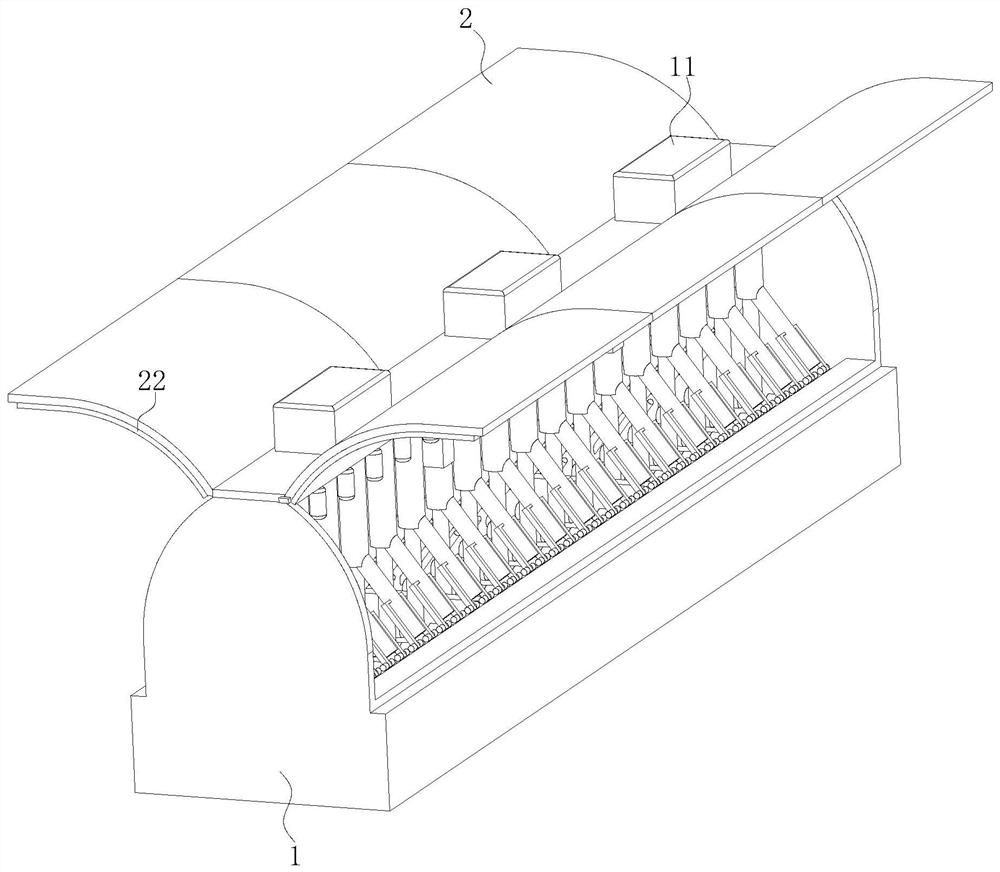

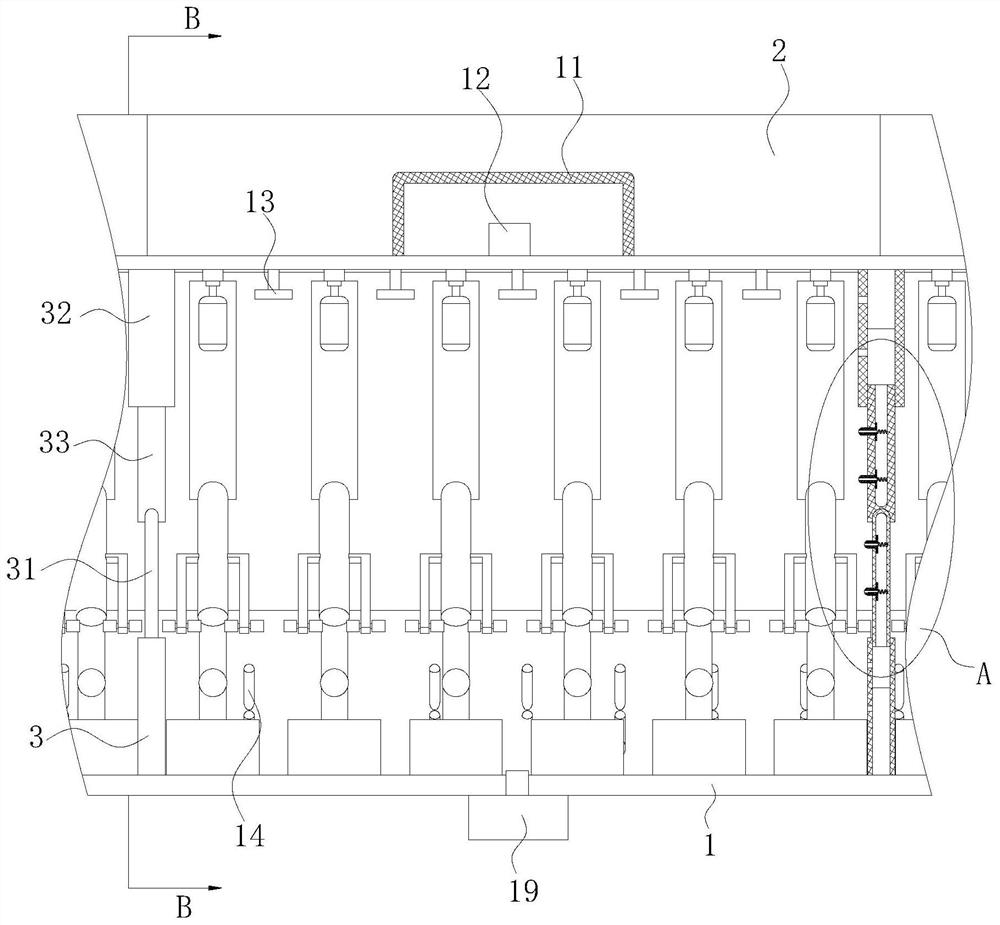

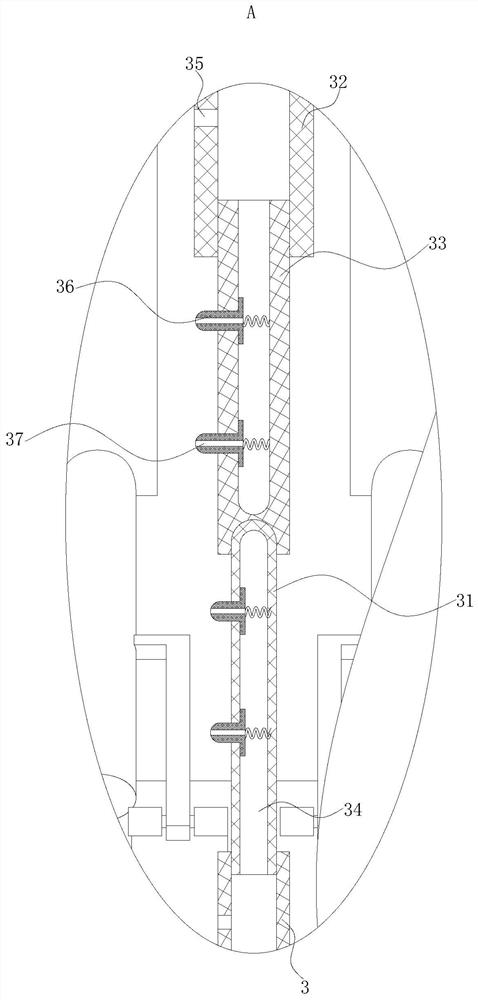

[0029] use Figure 1-Figure 5 A chemical fiber spinning machine according to an embodiment of the present invention will be described as follows.

[0030] Such as Figure 1-Figure 5 As shown, a chemical fiber textile machine according to the present invention includes a body 1 and a machine cover 2; spinning equipment is installed in the cavity of the body 1; Evenly arranged electric rotating shafts; each of the electric rotating shafts is fixedly connected to the machine cover 2, and the cover 2 is arc-shaped design; the top end surface of the body 1 is fixedly connected with a uniformly arranged storage box 11, and the storage box 11 are all placed in the centerline position of the cover on the opposite side; gas and liquid carbon dioxide are all housed in each of the storage boxes 11; a pressure device 12 is fixedly connected in each of the storage boxes 11, and The pressure devices 12 are all electrically connected to the controller through wires; the inner surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com