Steel beam hoisting method

A hoisting method and technology for steel girders, applied in bridges, bridge construction, transportation and packaging, etc., can solve problems such as difficult installation and large volume of steel girders, and achieve the effects of reducing construction period, improving construction quality, and simple and fast construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

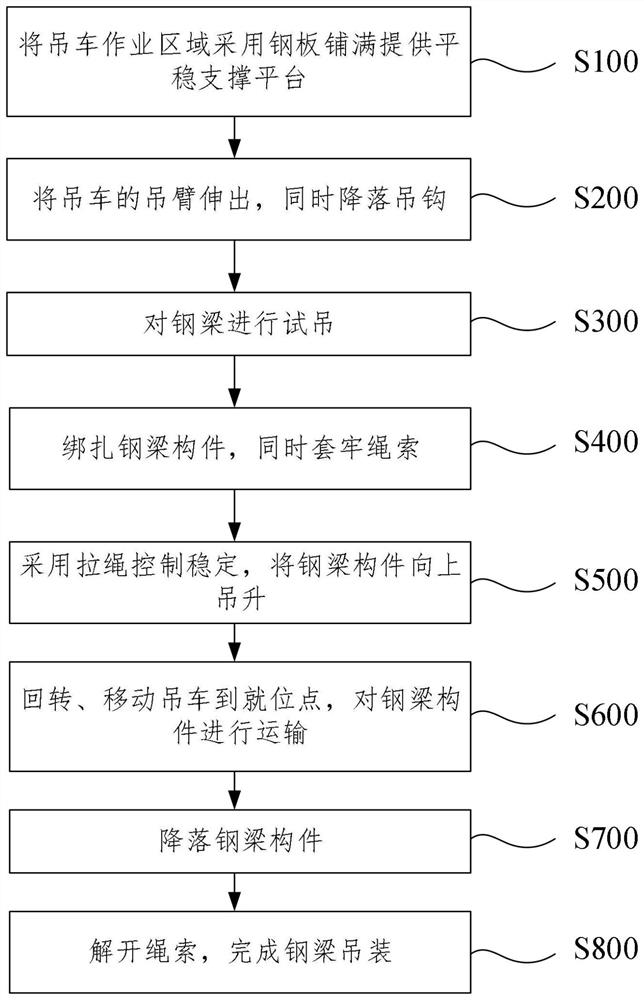

[0031] like figure 1 As shown, a steel beam hoisting method in this embodiment includes the following steps:

[0032] Step S100, covering the crane operation area with steel plates to provide a stable support platform;

[0033] Step S200, extending the boom of the crane and lowering the hook at the same time;

[0034] Step S300, carrying out trial lifting of the steel beam;

[0035] Step S400, tying up the steel beam members, while fastening the ropes;

[0036] Step S500, using a stay rope to control the stability, and hoisting the steel beam member upward;

[0037] Step S600, rotating and moving the crane to the in-position point, and transporting the steel beam member;

[0038] Step S700, dropping the steel beam member;

[0039] Step S800, untie the rope to complete the hoisting of the steel beam.

[0040] The technical effect achieved by this embodiment is: through a steel beam hoisting method of this embodiment, the construction method is simple and fast, and the hoi...

Embodiment 2

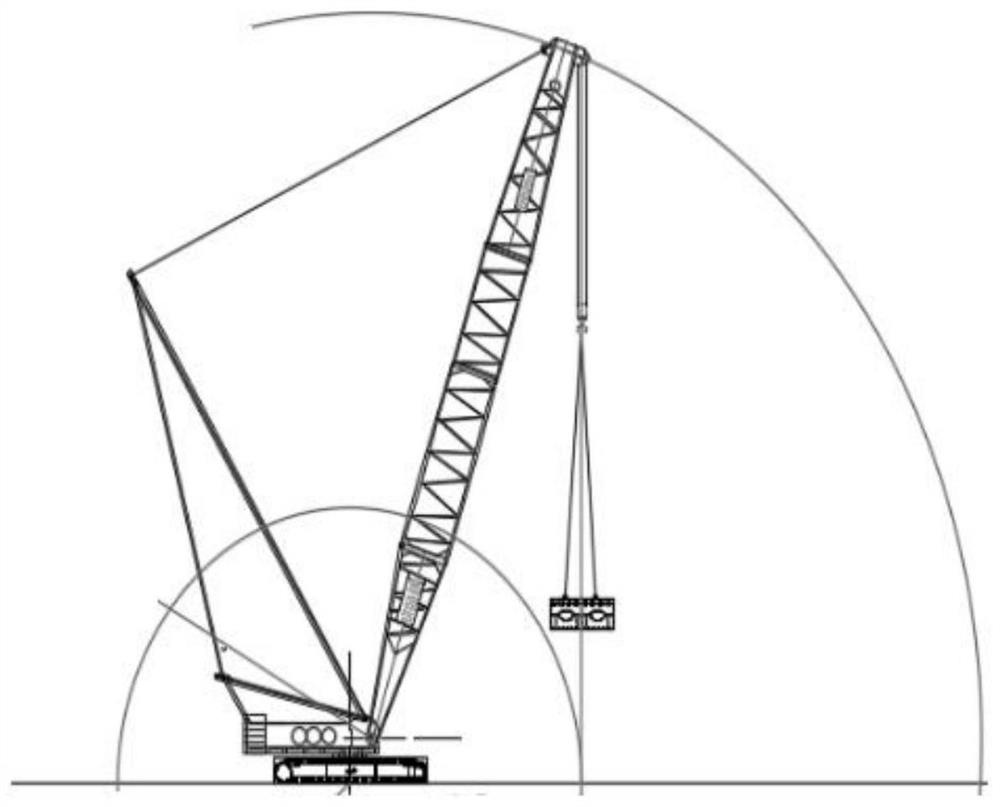

[0042] like figure 1 and figure 2 As shown, a steel girder hoisting method in this embodiment includes all the technical features in Embodiment 1. In addition, the thickness of the steel plate used in step S100 is 20cm to protect the road surface from being damaged and prevent the crane from hoisting the weight. Excessive concentration will damage the road surface.

[0043] Specifically, the steel girders transported to the site will be reassembled, assembled into a hoisting section, and the elevation of the pad stone of the main line bridge will be remeasured, and the steel girder support will be installed after the comparison with the design value is correct. After the support is installed, re-measure the elevation of the support; set up temporary supports; hoist the steel girders at different positions in sequence, and after the steel box girder welding and high bolt screwing are completed, unload and remove the temporary supports.

[0044] In some optional embodiments, ...

Embodiment 3

[0049] like figure 1 and figure 2 As shown, a steel beam hoisting method in this embodiment includes all the technical features in Embodiment 2. In addition, step S300 specifically includes: when the test hoisting reaches a height of 5cm to 10cm, perform a hover inspection , Check whether there are potential safety hazards, and continue to lift after confirming that it is correct. The steel beam is equipped with a lifting point, and the lifting point is connected to the wire rope with a snap ring when hoisting.

[0050] In some optional embodiments, step S400 specifically further includes: the steel girder binding should be firm, the binding point and the center of gravity of the steel beam component should be symmetrical to each other, and the center of the binding point should be aligned with the center of gravity of the object and higher than the center of gravity of the component, so that after the component is hoisted It is stable and does not cause accidents due to ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com