Pre-buried point hanging type mounting structure of assembly type wallboard

An installation structure and prefabricated technology, which is applied in building construction, covering/lining, construction, etc., can solve the problems of constant replacement, poor flatness, poor construction efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

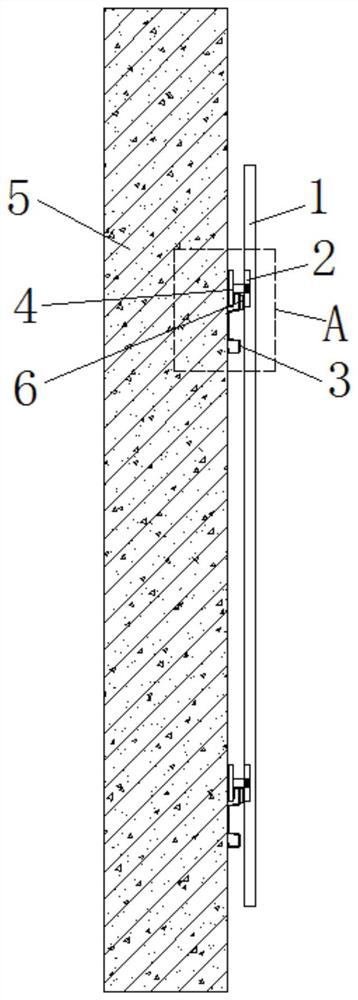

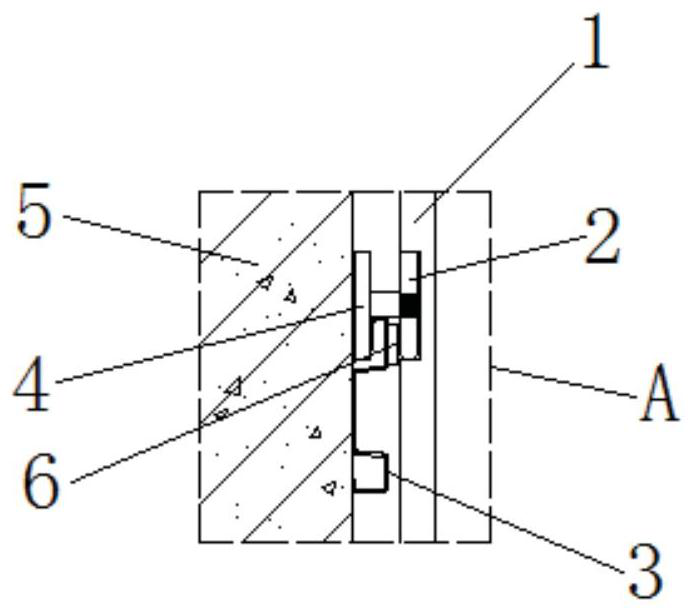

[0035] see Figure 1 to Figure 2 , the figure shows a pre-embedded point-mounted installation structure of a prefabricated wall panel provided by Embodiment 1 of the present invention, including: a wall panel 1; a connector 2, which is embedded on the reverse side of the wall panel 1; a keel 3 , which is fixedly connected to the wall body 5; the hook 4, whose inner side is connected with the top of the keel 3, and whose outer side is threadedly connected with the connector 2. Wherein, the connecting piece 2 is a connecting nut.

[0036] The pre-embedded point-hanging installation structure of the prefabricated wallboard provided in this embodiment includes the main wallboard 1, the connection 2 pieces, the keel 3 and the hanging piece 4, the keel 3 is fixedly connected to the wall body 5, and the connecting piece 2 is pre-embedded on the opposite side of the wallboard 1, and the wallboard 1 is connected with the hooking piece 4 through the connecting piece 2.

[0037] During...

Embodiment 2

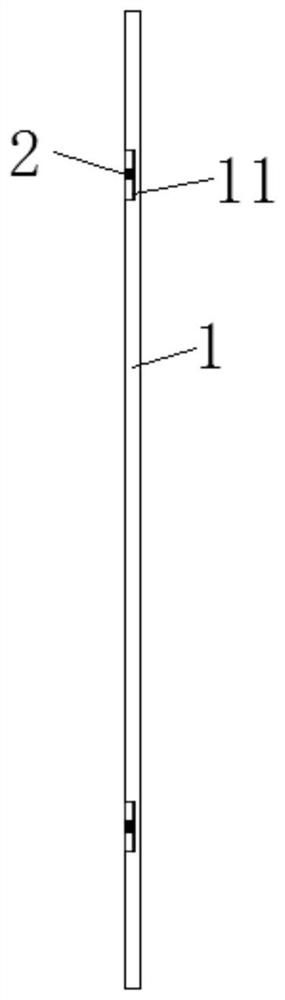

[0044] see Figure 3 to Figure 4 , the figure shows a pre-embedded point-mounted installation structure of a prefabricated wall panel provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following improved technologies Solution: the back of the wallboard 1 is provided with an installation hole 11, and the connector 2 is arranged in the installation hole 11; the depth of the installation hole 11 is consistent with the thickness of the connector 2. Through the setting of the above structure, the quick connection between the wall panel 1 and the hook 4 can be facilitated, and the flatness of the wall panel 1 can be improved at the same time.

Embodiment 3

[0046] see figure 2 , Figure 6 , the figure shows a pre-embedded point-mounted installation structure of a prefabricated wallboard provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following improved technologies Solution: the hitch 4 includes a hitch plate 41 and a connecting column 42, the connecting post 42 is arranged on one side of the hitch plate 41, and both are perpendicular; the top of the connecting post 42 is provided with a threaded head 43, and the threaded head 43 is connected to the connecting nuts. Through the setting of the above structure, the threaded head 4 is directly connected with the connecting nut, which not only has good connection strength, but also is fast and convenient to connect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com