Engine cleaning system and method

A cleaning system and engine technology, which is applied in the direction of engine components, machine/engine, engine lubrication, etc., can solve the problems of greater impact, reduce lubrication effect, increase cleaning cost, etc., and achieve the best cleaning effect and cleaning efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

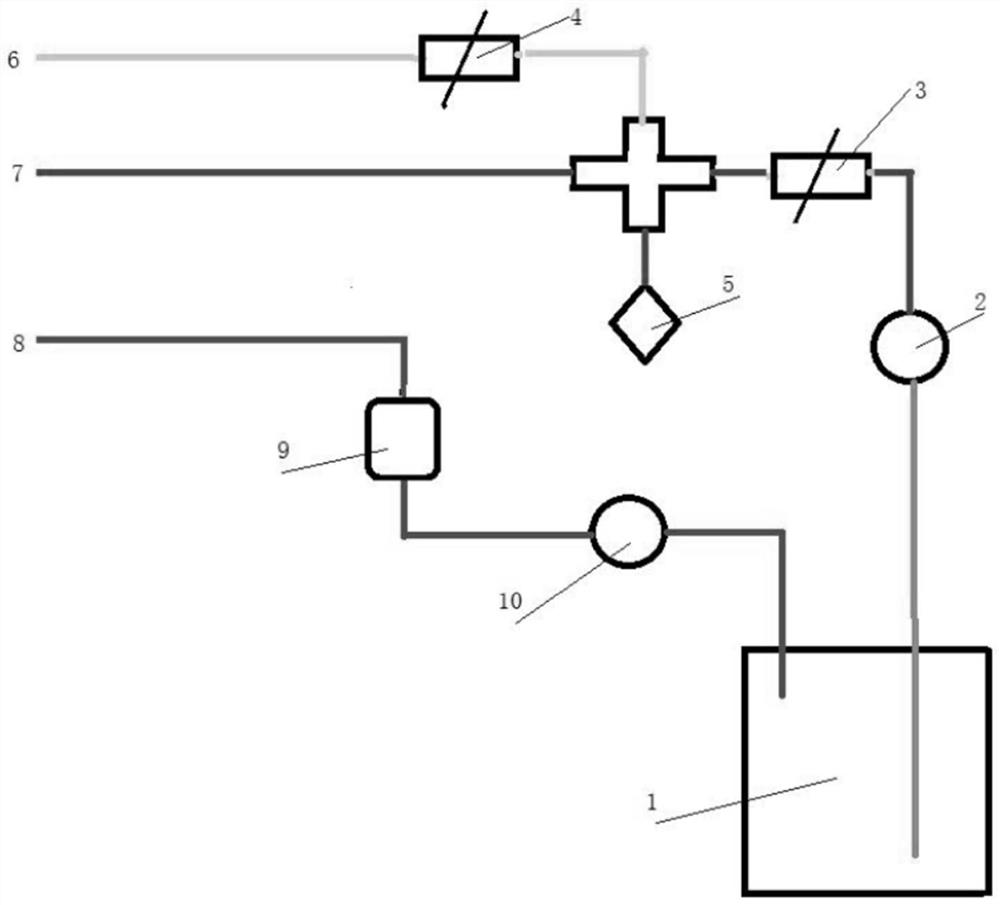

[0027] Below we will further describe this technical solution of the present invention in detail in conjunction with the accompanying drawings and specific examples.

[0028] Follow the steps below when cleaning the engine,

[0029] First, open the oil drain port of the engine oil pan, and the dirty oil inside the engine will be discharged naturally under the action of gravity.

[0030] When there is no obvious oil discharge from the oil pan outlet of the engine, connect the air pipe 6 to the compressed air source, connect the cleaning pipe 7 to the interface of the engine oil filter, and connect the recovery pipe 8 to the oil outlet of the engine oil pan. connect.

[0031] Then, when cleaning the engine, you can choose the cleaning program specially set for this type of engine to achieve the best cleaning effect, or use the conventional cleaning steps. Although there will be many models of the same car manufacturer, they will share the same engine. Therefore, it is feasible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com