Burr cleaning mechanism for gear machining

A burr and gear technology, which is applied in the field of burr cleaning mechanism for gear processing, can solve the problems of poor burr cleaning efficiency and difficult cleaning of the inclined surfaces at the upper and lower ends of the tooth block, and achieves the effect of fast efficiency, reduced impact and good cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

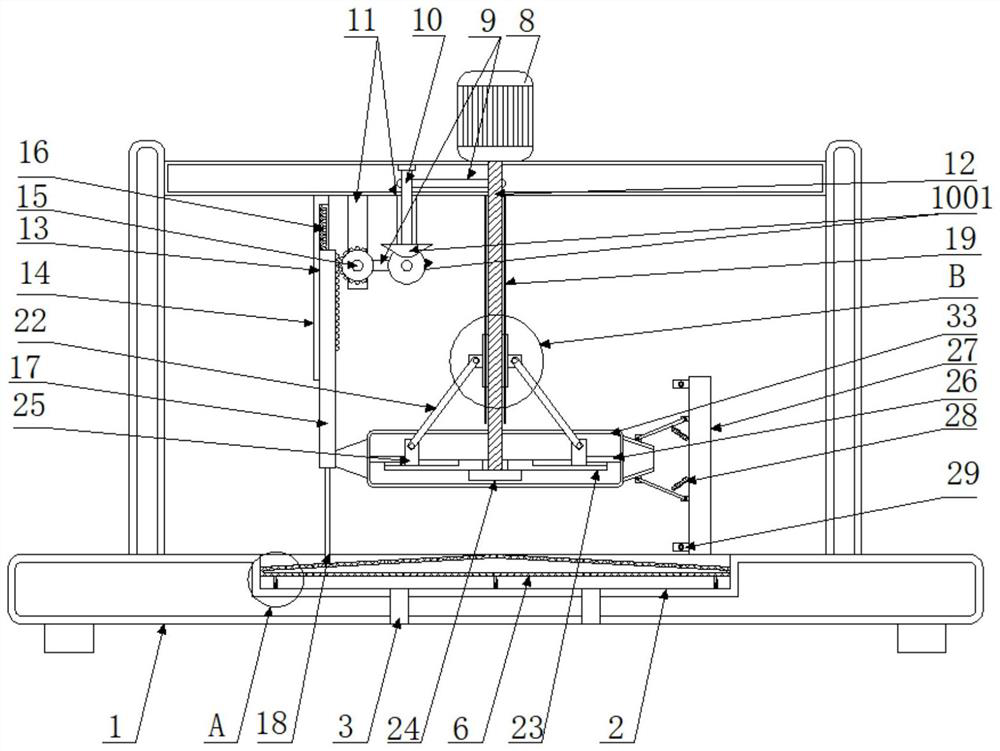

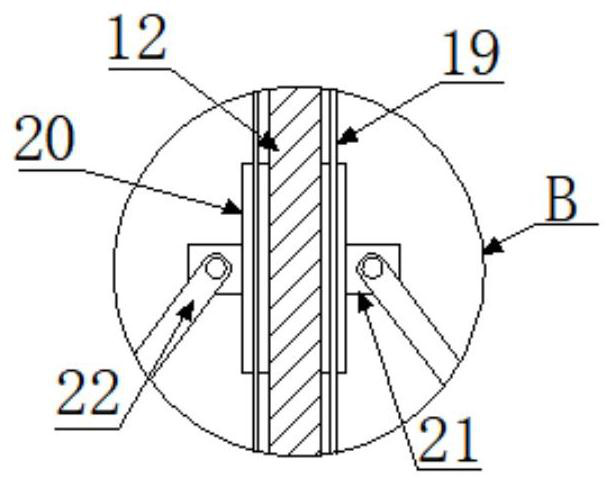

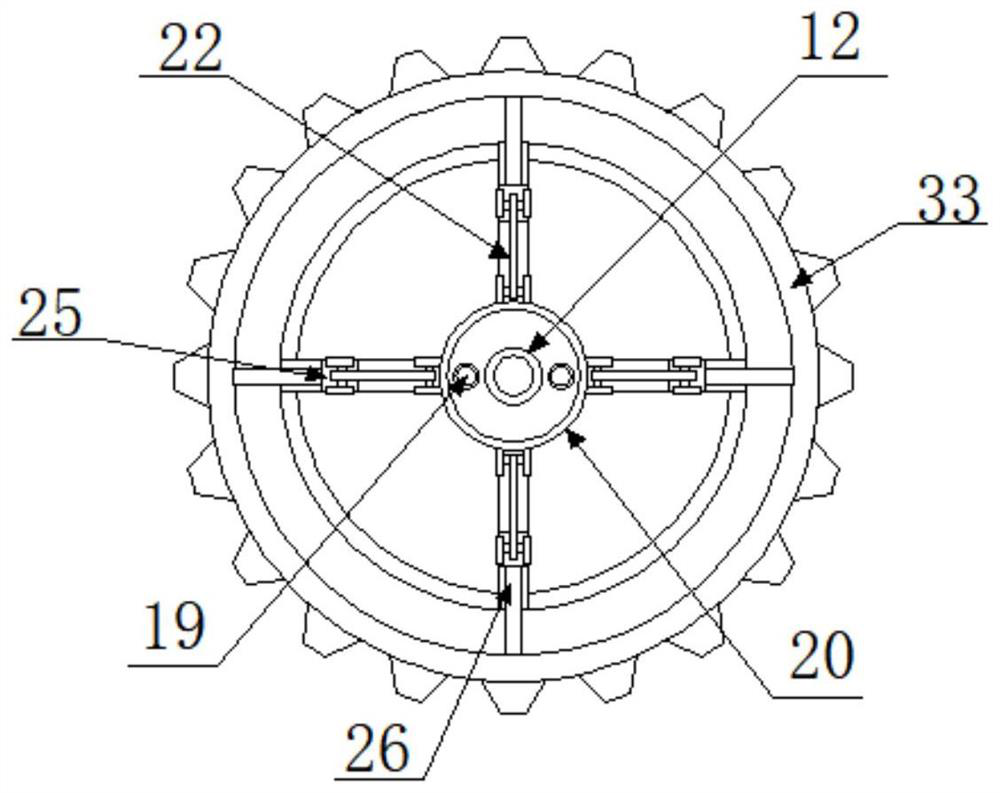

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0031] Gears are one of the transmission mechanisms in industrial production and life. The gears process the metal block into the shape of a gear through a milling cutter. After cutting by the milling cutter, there are many burrs on the outer surface of the tooth block on the initial shape of the gear. It is necessary to use a burr cleaning mechanism to clean the burrs, and some existing burr cleaning mechanisms for gear processing still have some shortcomings when they are used, such as:

[0032] Existing gear processing and deburring equipment, such as a deburring equipment described in CN201810674987.3, uses a driving device to make the grinding block grind the tooth block on the gear. In this application, only th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com