Machine dedusting mechanism applied to square lithium battery winding machine

A lithium battery and winding machine technology, applied in the direction of secondary batteries, non-aqueous electrolyte batteries, and cleaning methods using gas flow, etc., can solve the problems that are difficult to meet the production and dust removal requirements, the cleaning effect of the whole machine is not obvious, and it is impossible to achieve high Efficiency and other issues, to achieve the effect of good cleaning effect, stable air pressure and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

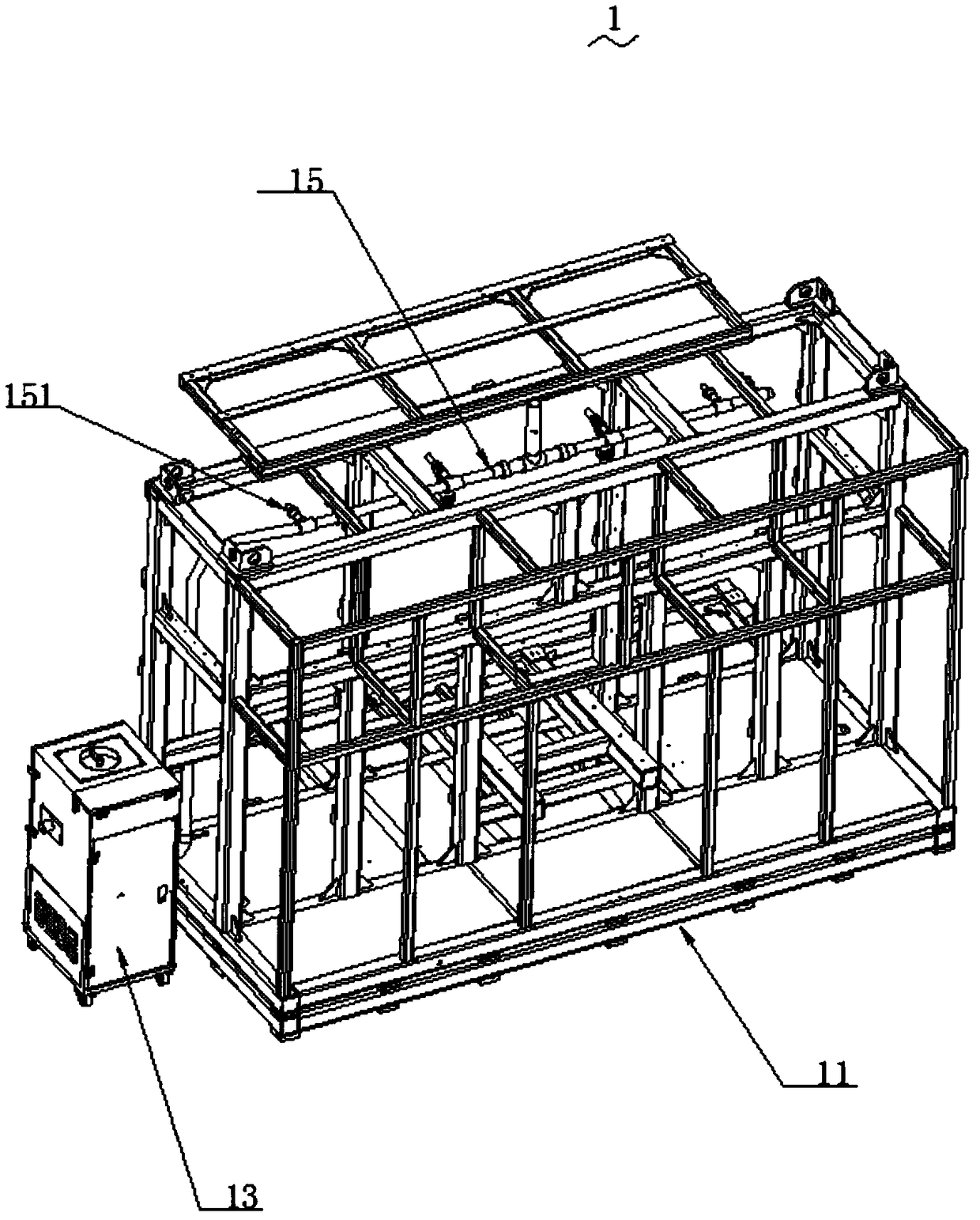

[0016] see figure 1 , a whole machine dust removal mechanism 1 applied to a square lithium battery winding machine in the present invention includes a chassis body 11 and a dust remover 13 arranged near the outside of the chassis body 11; The main air duct 15 and several sub-air ducts 151 connected with the main air duct 15; the main air duct 15 communicates with the dust collector 13 on the outside of the chassis body 11; the main air duct 15 is bent in an L shape, It includes a vertical air duct and a horizontal air duct, and the horizontal air duct is arranged on the top part of the inside of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com