Novel multi-rope friction hoisting rope oiling device and implementation method thereof

A friction boosting and refueling device technology, which is applied in the input of lubricating oil, engine temperature, signal processing, etc., and can solve problems such as low refueling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

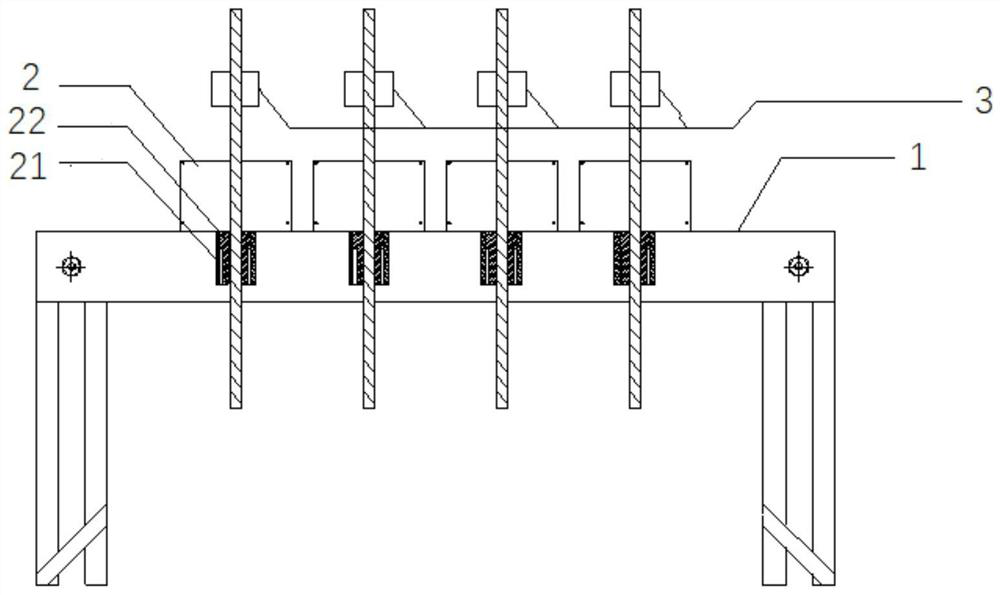

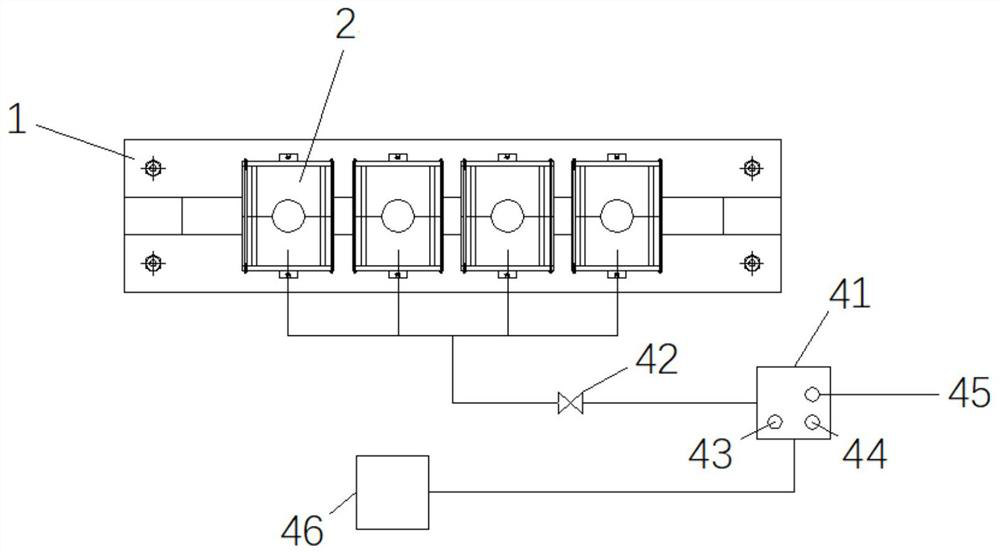

[0110]please continue Figure 1-Figure 3 As shown, the present invention also provides an implementation method of a novel multi-rope friction hoisting wire rope refueling device, comprising the following steps:

[0111] Step 1: First, build a split-type fixing frame 1 according to the site conditions;

[0112] Step 2: According to the number of wire ropes to be refueled, the corresponding number of identical oil filling boxes 2 are processed;

[0113] Step 3: move the split-type fixing frame 1 to a designated position;

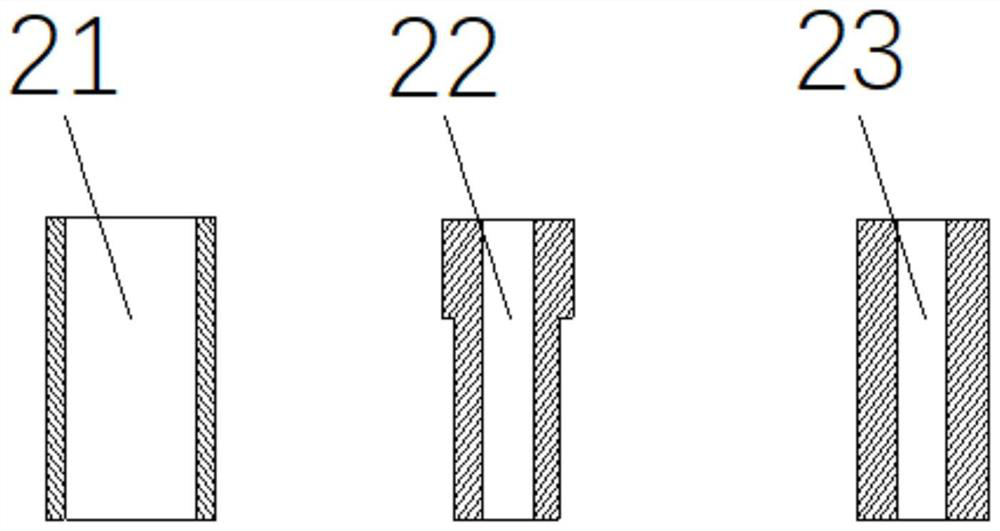

[0114] Step 4: Preliminarily place each oil filling box 2 to an appropriate position according to the position of each wire rope, and set each calibration sleeve 23 on the corresponding wire rope and install it into the sleeve groove to calibrate each oil filling box 2;

[0115] Step 5: After the calibration is completed, disassemble each calibration sleeve 23 and sleeve the oiling sleeve 22 and the tightening adjustment sleeve 21 in sequence. After the sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com