Regional cooperative reinforced fluidized bed heater

A fluidized bed and heat extractor technology, applied in fluidized bed heat exchangers, catalytic cracking, heat exchanger shells, etc., can solve the limitation of improving heat exchange efficiency and reduce the internal stability of fluidized bed heat extractors And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

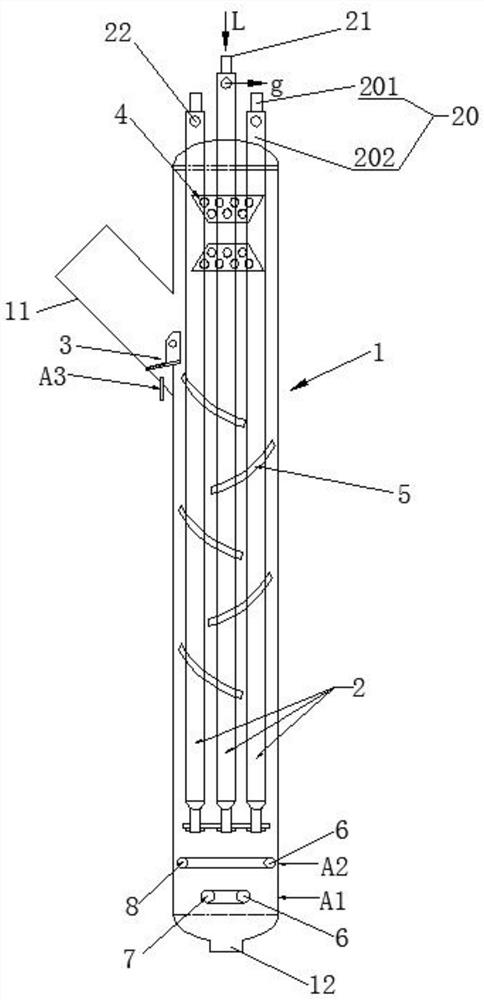

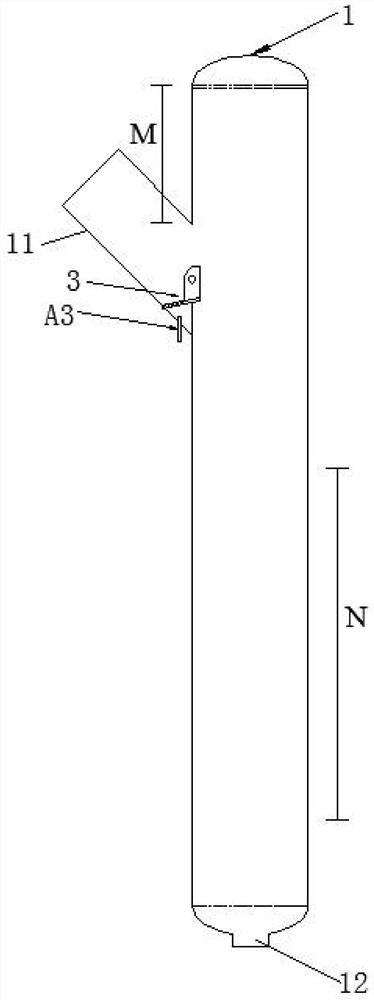

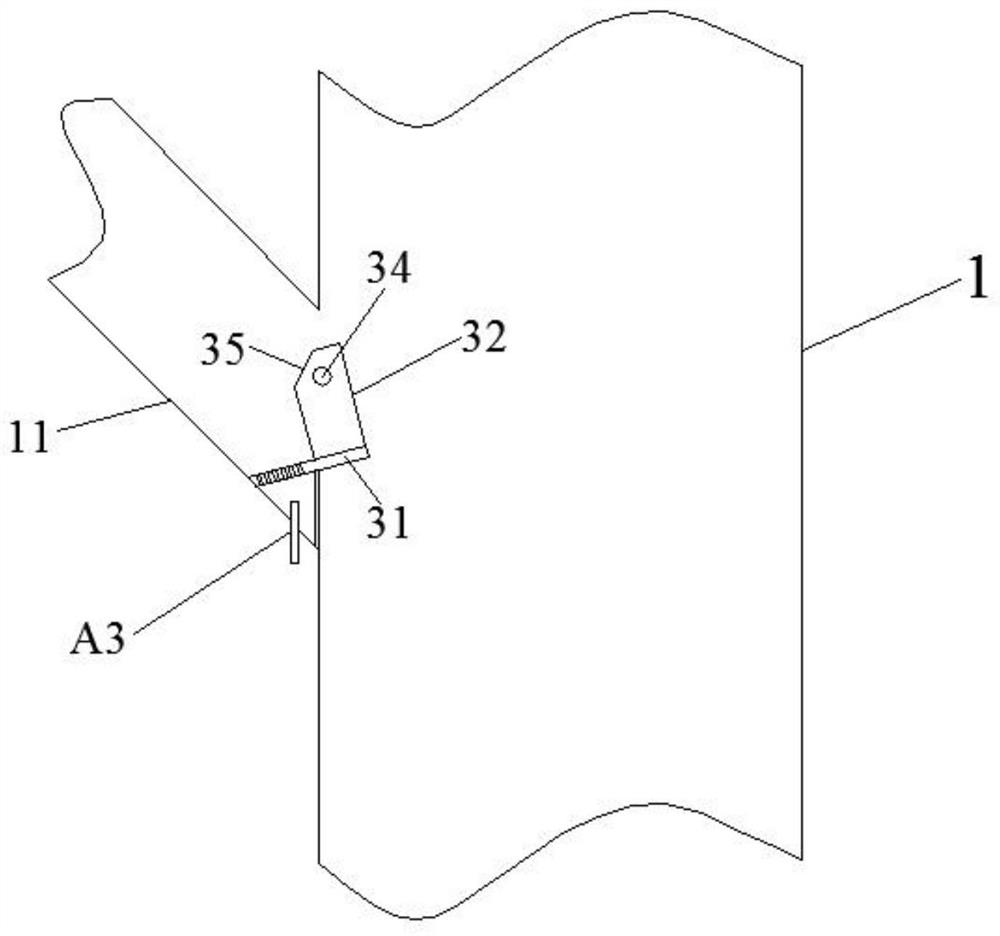

[0042] Embodiment 1 provides a fluidized bed heat extractor with regional synergistic enhancement, and its structure is described in detail below.

[0043] reference figure 1 with figure 2 , The fluidized bed heat extractor includes a shell 1, which is a round tank type and is set upright. A plurality of heat exchange tubes 20 are vertically distributed in the shell 1, and the upper part of the shell 1 is provided with a catalyst inlet. The bottom of the casing 1 is provided with a catalyst outlet 12, and the inside of the casing 1 is divided into a catalyst inlet influence zone, a dilute phase zone M at the upper part, a dense phase zone N at the lower part, and a gas distributor influence zone at the bottom; Area M and dense phase area N are respectively located above and below the catalyst inlet influence zone. The catalyst inlet is inclined upwardly with a catalyst inlet inclined pipe 11, and the catalyst inlet in the catalyst inlet inclined pipe 11 is provided with a region...

Embodiment 2

[0074] On the basis of Embodiment 1, Embodiment 2 provides another structure and placement method of the dilute phase guide vane 4 and the dense phase guide vane 5, and the structure and placement method will be described in detail below.

[0075] reference Picture 9 , The dilute phase guide vane 4 and the dense phase guide vane 5 are both bent plate structures, and their longitudinal section is in the shape of a broken line, that is, the dilute phase guide vane 4 and the dense phase guide vane 5 are both broken line-shaped bent plates. The dilute phase guide vane 4 is provided with a plurality of dilute phase guide vane guide holes 40, and the plurality of dilute phase guide vanes 4 are arranged spirally from bottom to top around the longitudinal center line of the casing 1 in the dilute phase region M Or they are staggered from bottom to top along the longitudinal centerline of the housing 1. The dense phase guide vane 5 is provided with a plurality of dense phase guide vane g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com