Tangential fretting wear test fixture for nuclear power fuel cladding tube and grillwork rigid convex body

A test fixture, fretting wear technology, applied in the direction of analyzing materials, testing wear resistance, measuring devices, etc., can solve the problem that the rigid convex body and the fuel cladding tube are small in size, the fixture is difficult to hold, and the corrosion resistance of the fixture is poor. To guarantee and other issues, to achieve the effect of high high temperature strength, simple and convenient operation, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

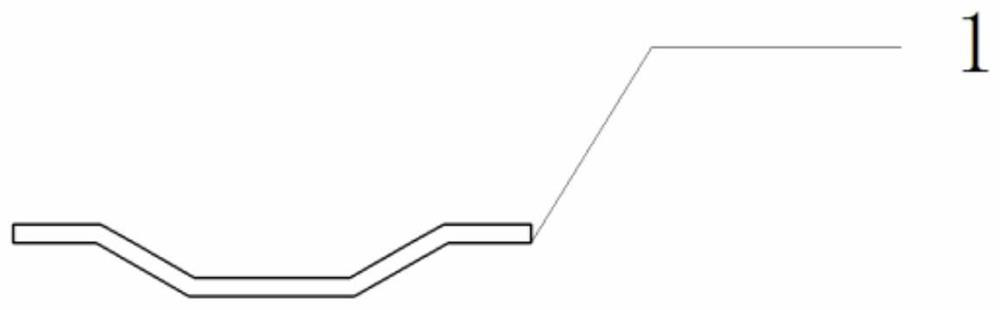

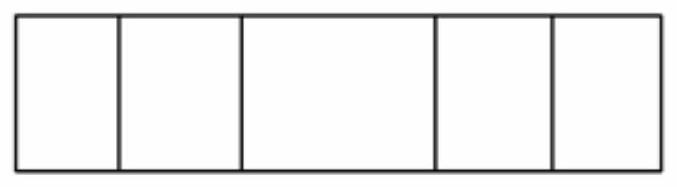

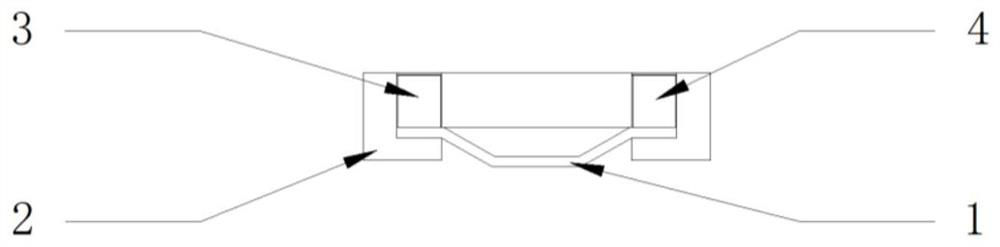

[0034] In the specific implementation process, the tangential fretting wear test fixture for the nuclear power fuel cladding tube and the grid rigid convex body in high temperature and high pressure water of the present invention mainly includes: a rigid convex body sample fixing block, a rigid convex body sample fastening stud , Rigid convex sample fixing block fixture, fixture fixing plate, fixture fixing bracket, cladding tube fixing base, arc-shaped clamping block, etc. Insert the rigid convex body sample into the rigid convex body sample fixing block, and lock the rigid convex body sample with the fastening stud, and then insert the fixed block into the lower opening of the rigid convex body sample fixing block groove And fix it with fastening screws, and finally fix the fixture of the rigid convex body sample fixing block on the fixture fixing plate and install the fixing plate on the fixture fixing bracket to realize the fixing of the rigid convex body sample. The cladd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com