Batch industrial CT detection system

A detection system, a technology in the chemical industry, applied in measurement devices, instruments, scientific instruments, etc., can solve problems such as difficulty, high cost, and incompetent detection technology, and achieve the effect of avoiding radiation environment and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

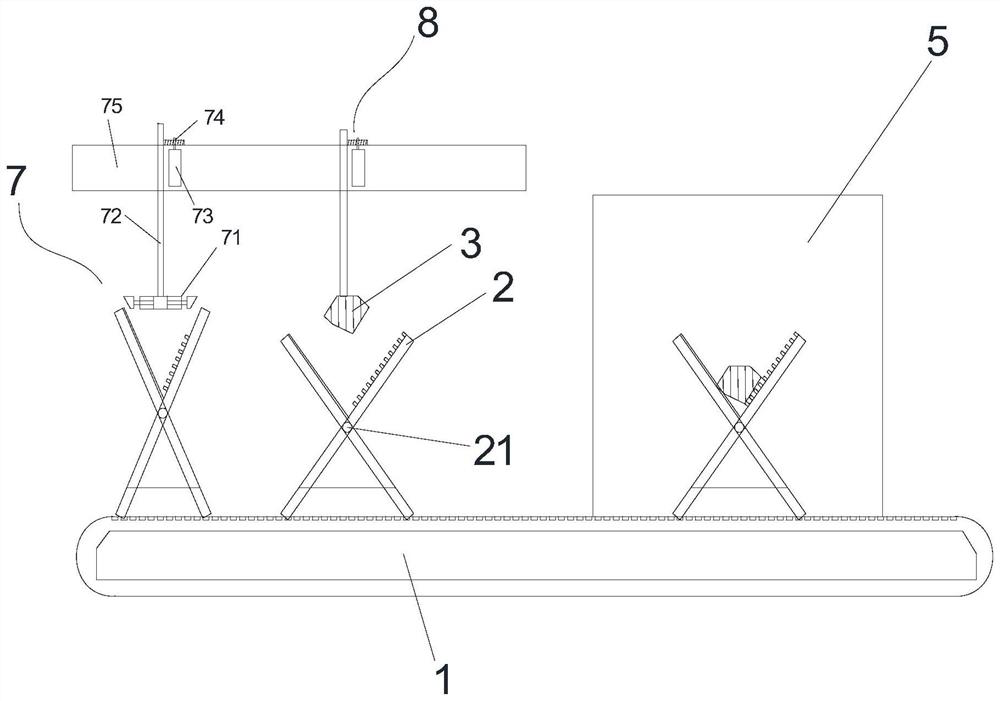

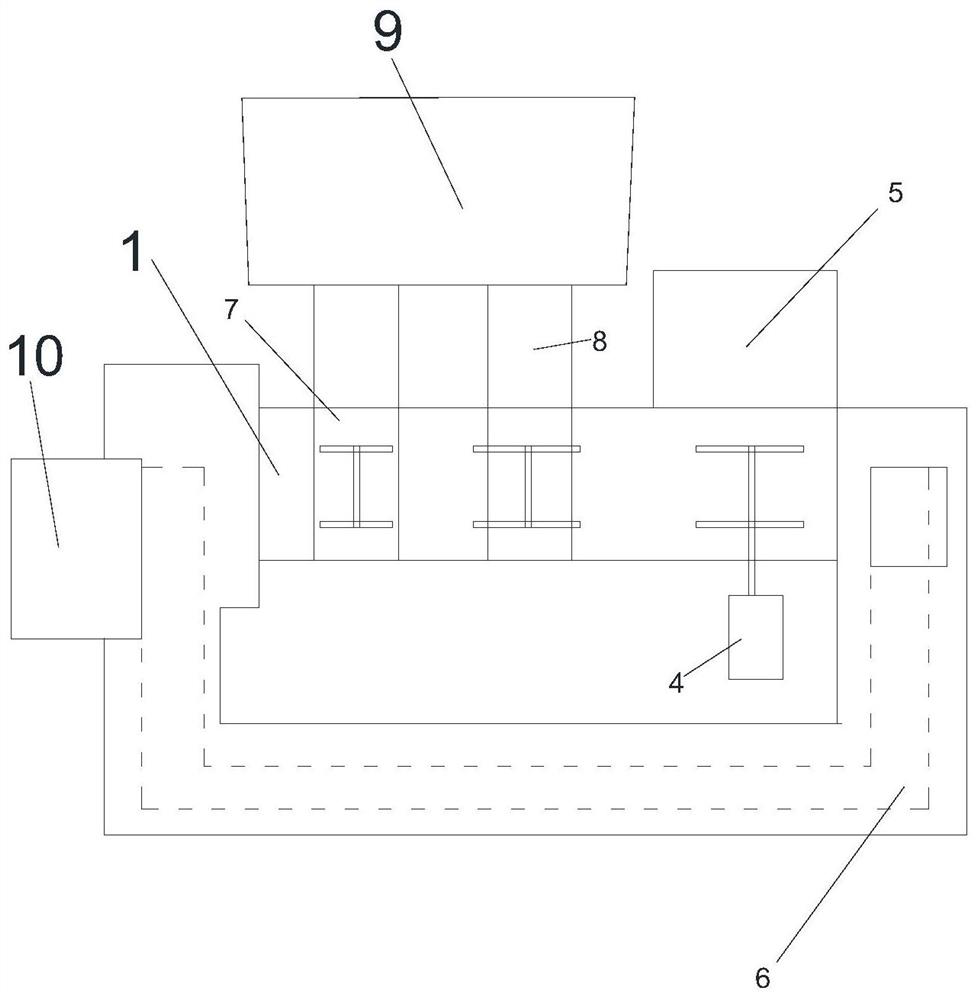

[0041] The batch industrial CT detection system in this embodiment includes a conveyor belt platform 1, a loading support frame 2, an industrial CT imaging device 5, a side push mechanism 4, a circulation conveying crane mechanism 6, a support frame expansion mechanism 7 and an upper Feeding mechanism 8, see figure 1 and figure 2 .

[0042] The conveyor belt platform 1 is a straight conveyor belt structure. The surface of the conveyor belt of the conveyor belt platform 1 is provided with a rubber limit groove. Increase the frictional force at the bottom of the loading support frame 2, so as to maintain the opening angle of the loading support frame 2.

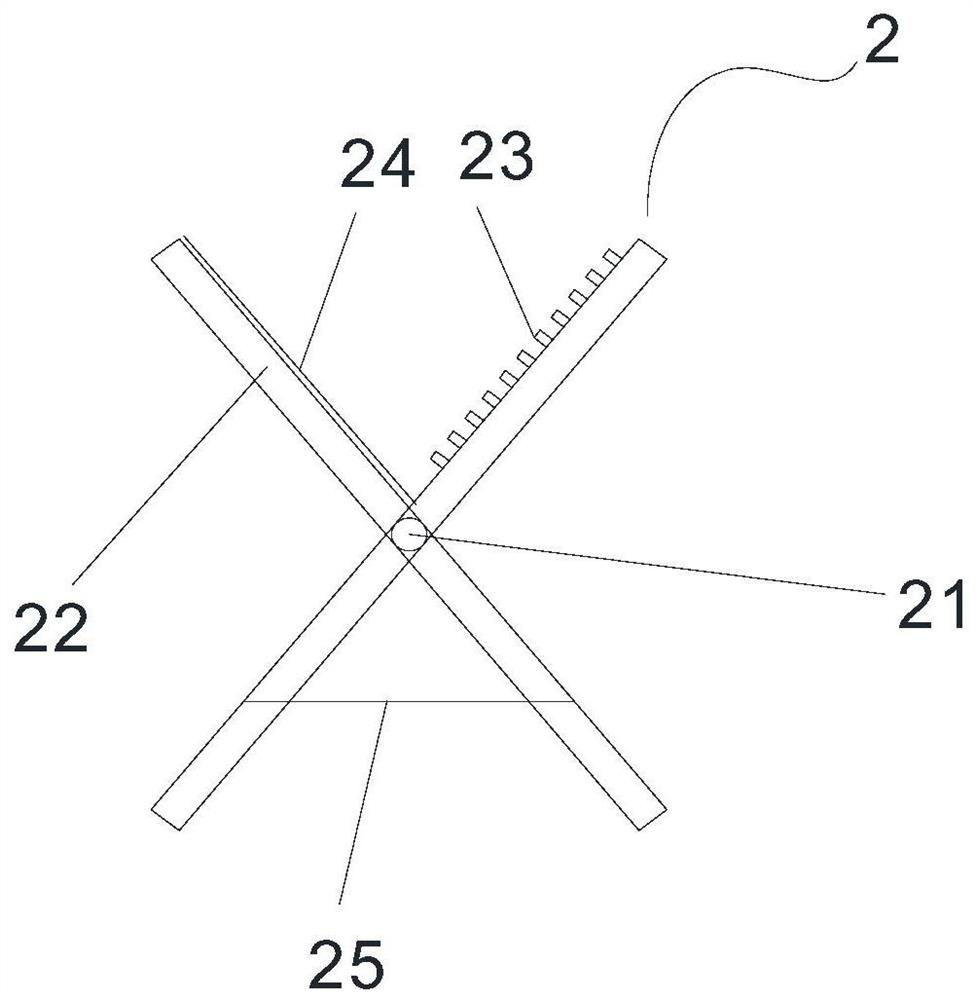

[0043] The loading support frame 2 is arranged on the conveyor belt platform 1, and the loading support frame 2 is a foldable structure. After the workpiece 3 is placed on the loading support frame 2, the loading support frame 2 can be folded adaptively. Adjust to match the outline of the workpiece 3 .

[0044] The indust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com