Efficient self-cleaning water curtain type waste gas multi-stage filtering method

A self-cleaning, graded filtration technology, applied in separation methods, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of reducing purification efficiency, poor exhaust gas filtration effect, interrupting the purification process, etc., and achieve the effect of improving the purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

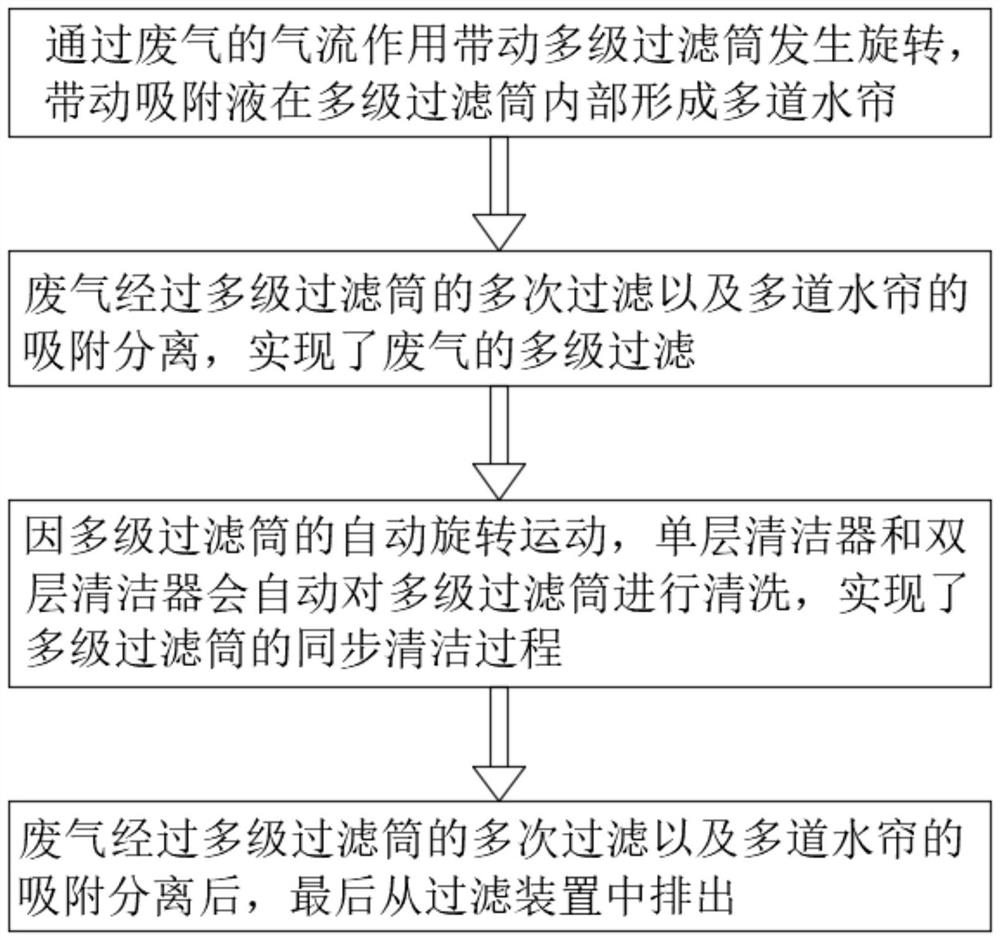

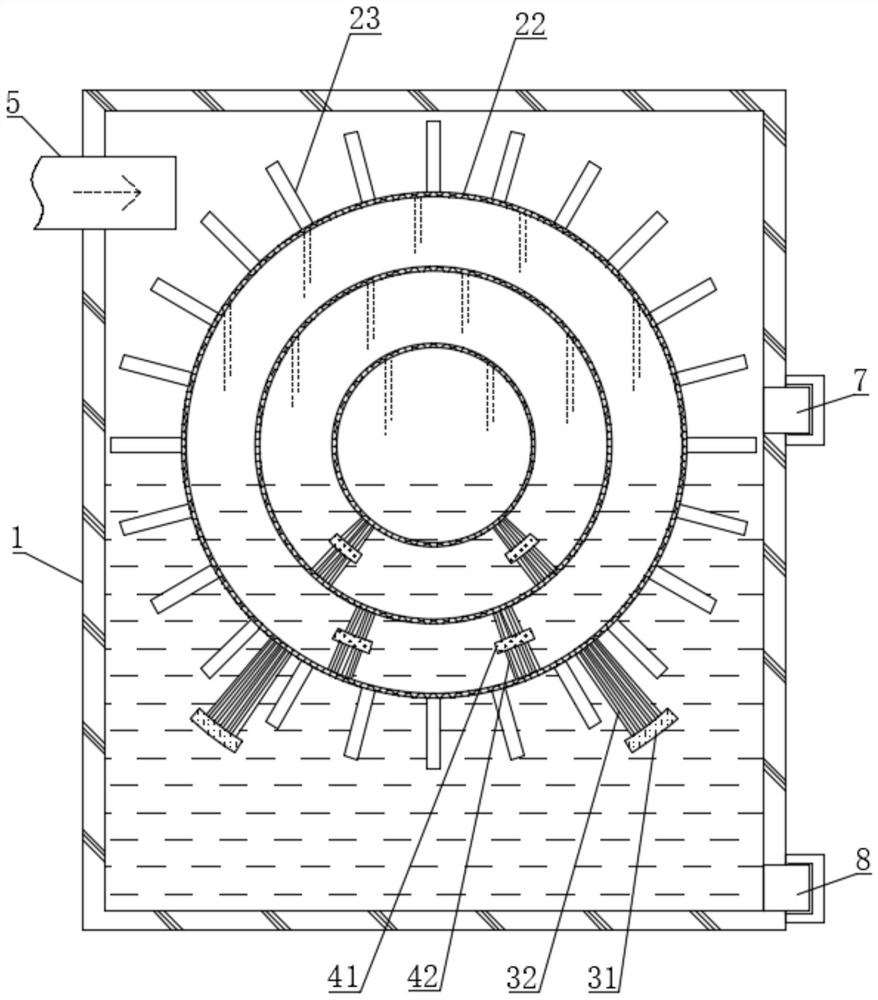

[0043] see figure 1 , a high-efficiency self-cleaning water curtain type exhaust gas multi-stage filtration method, comprising the following steps:

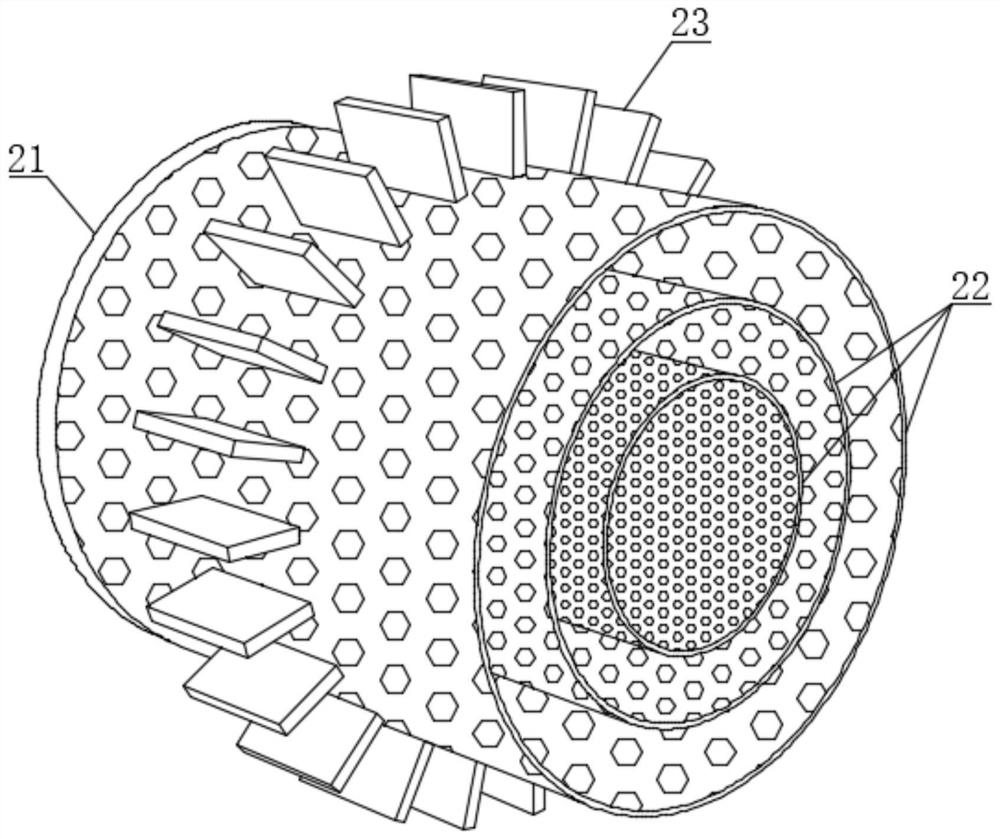

[0044] S1. The exhaust gas is passed into the filter device, and the multi-stage filter cartridge is driven to rotate by the air flow of the exhaust gas, thereby driving the adsorption liquid to form multiple water curtains inside the multi-stage filter cartridge;

[0045] S2. The exhaust gas enters the multi-stage filter cartridge. After multiple filtrations of the multi-stage filter cartridge and the adsorption and separation of the multi-channel water curtain, the multi-stage filtration of the exhaust gas is realized. Part of the particulate matter in the exhaust gas enters the adsorption liquid along with the water curtain, and the other Part of it is adsorbed on the multi-stage filter cartridge;

[0046] S3. Due to the automatic rotation of the multi-stage filter cartridge, a pair of single-layer cleaners and multiple doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com