Efficient anaerobic bioreactor for industrial wastewater treatment

An anaerobic biological and industrial wastewater technology, applied in the field of anaerobic bioreactors, can solve the problems of affecting the efficiency of internal circulation, clogging of riser and return pipes, and paralysis of internal circulation, so as to ensure continuous and efficient operation and reduce the probability of clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

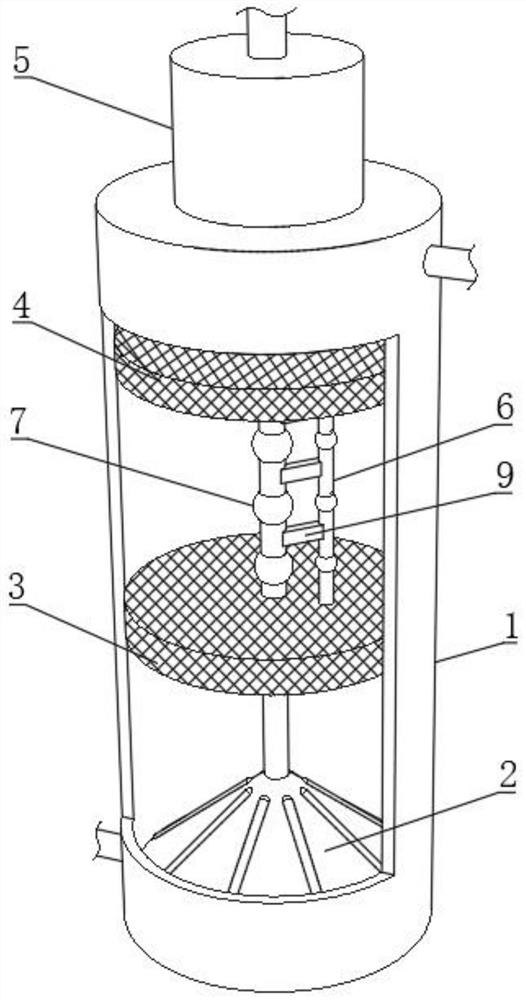

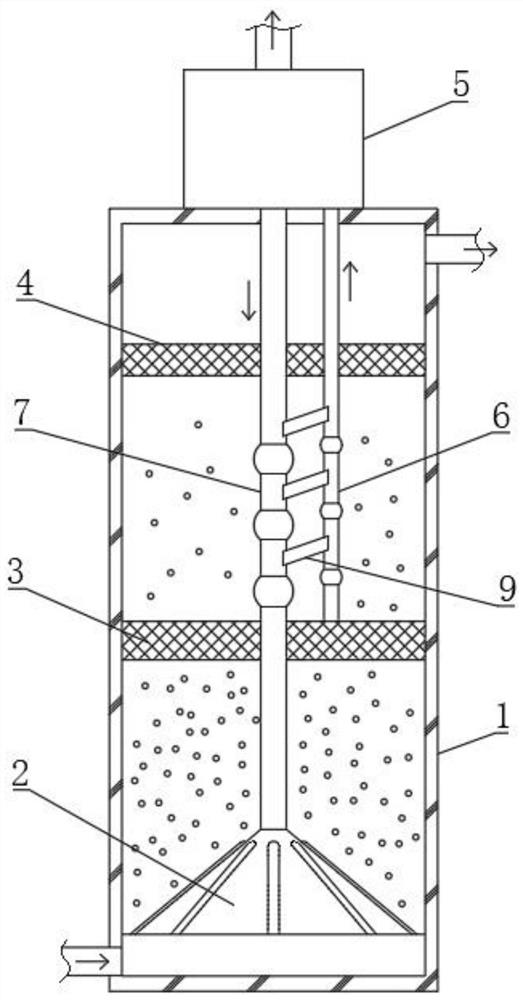

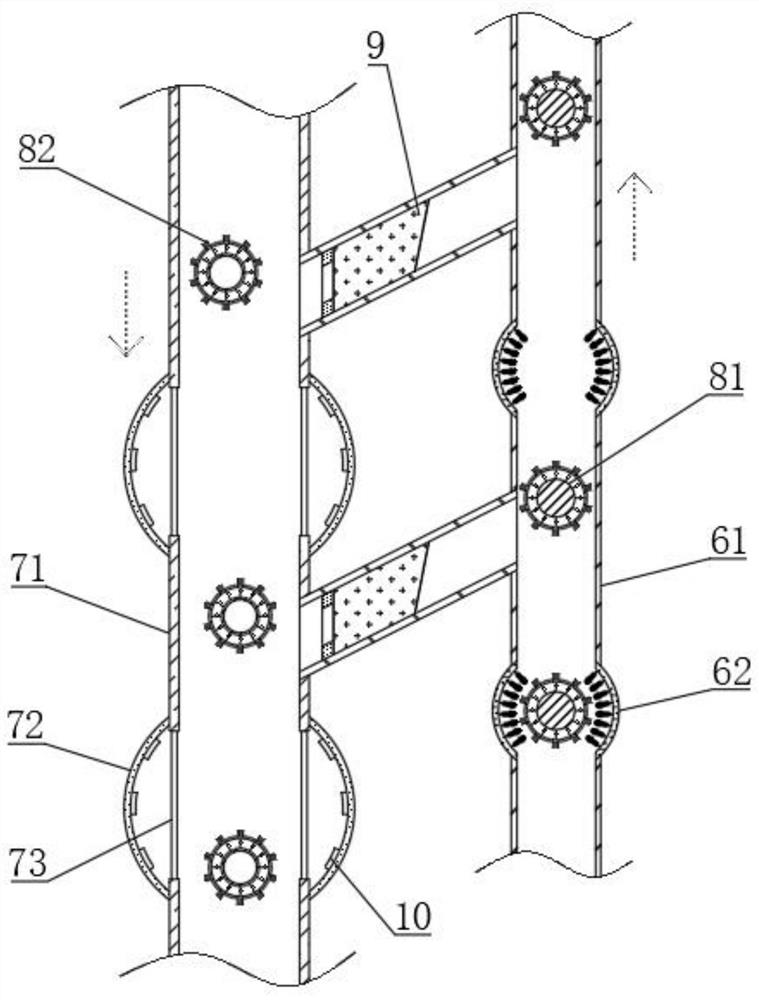

[0045]Seefigure 1 withfigure 2 A high-efficiency anaerobic bioreactor for industrial wastewater treatment, including reactor housing 1, and the inside of the reactor housing 1 is fixedly mounted and mounted with a wasteler 2, one-stage three-phase separator 3 and two. The stage three-phase separator 4, the decormer 2 and the first stage three-phase separator 3 are filled with active sludge, and the upper end of the reactor housing 1 is fixedly mounted with a gas-liquid separator 5, reactor. The side end of the housing 1 is fixedly connected to the water pipe and the water pipe, the water pipe and the wasteler 2 are in communication, and the water pipe is located on the upper side of the secondary three-phase separator 4, and there is also an improvement tube inside the reactor housing 1. 6 and the return pipe 7, the lift pipe 6 is fixed to the first stage three-phase separator 3 and the gas-liquid separator 5, the upper end of the return pipe 7 penetrates the reactor housing 1 and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com